Cell Line Development For Biologics

Cell line development creates stable cell cultures that continuously secrete or express a specific therapeutic protein or antibody. These cell lines are reliable factories for large-scale production of biopharmaceuticals, ensuring consistent quality and yield. Well-developed cell lines accelerate drug development, reduce costs, and bring new therapies to the market faster. They are a critical bridge between scientific discovery and clinical application.

Table Of Contents:

- Introduction To Cell Line Development

- Key Factors Influencing Cell Line Development

- Types Of Cell Lines And Their Applications

- Ensuring A Stable Cell Line

- Cell Banking

- Characterization

- Regulatory Considerations

- Conclusion And Summary

- Frequently Asked Questions (FAQs)

Introduction To Cell Line Development

Cell line development entails rigorous characterization and banking processes that safeguard purity, stability, and traceability, which are necessary to meet regulatory requirements and ensure the safety and efficacy of the final therapeutics. Additionally, the advent of continuous biomanufacturing demands robust and consistently productive cell lines capable of extended periods of operation, which cell line development facilitates.

However, developing the right cell line involves selecting the ideal host, choosing a cell line engineering process, developing stable clones, testing efficacy through characterization, maintaining the product’s stability, cell banking, scaling up, and, throughout the process, navigating byzantine regulatory waters. This comprehensive guide walks drug developers through each stage of cell line development and anticipates future trends.

Understanding Cell Lines In Biopharmaceuticals

Biopharmaceutical manufacturers must first select the appropriate cell line for their pharmaceutical product. But what is the “right” cell line? The answer depends on the characteristics of the desired product. First, companies weigh various factors to ensure that the chosen cell line meets the specific requirements of the production process and the desired product, such as:

- Host cell line: Factors such as protein complexity, post-translational modifications, and scalability influence the selection of the host cell line.

- Productivity: The selected cell line should be capable of producing high levels of the target protein. This can be assessed through initial screening of cell lines for desired protein expression.

- Stability: The stability of the cell line over multiple generations is crucial for consistent production of the target protein. Cell lines that exhibit stable protein expression over time are preferred.

- Growth characteristics: The cell line's growth rate and doubling time should be compatible with the production process requirements. Fast-growing cell lines are often preferred for efficient bioproduction.

- Post-translational modifications: Some proteins require specific post-translational modifications (e.g., glycosylation, phosphorylation) for proper function. The cell line should be capable of performing these modifications if needed.

- Regulatory considerations: Cell lines used for biopharmaceutical production must comply with product safety, efficacy, and quality requirements. They should also be free from adventitious agents and have a well-characterized genetic profile.

- Scalability: The selected cell line should be scalable to large production volumes in bioreactors while maintaining productivity and product quality.

- Cost and intellectual property: The costs of cell line development, licensing requirements, and associated intellectual property rights should also be considered.

Types Of Cell Lines

The most popular host cell lines are from mammalian sources, including:

- Chinese hamster ovary (CHO) cells: CHO cells are the predominant mammalian cell line used to produce therapeutic proteins and monoclonal antibodies. They have been extensively optimized and characterized, making them the industry standard for biopharmaceutical manufacturing.

- Baby hamster kidney (BHK) cells: BHK cells were among the earliest cell lines used for biopharmaceutical production, particularly for viral vaccines and recombinant proteins.

- Mouse myeloma cell lines (NS0, Sp2/0): These mouse cell lines were previously used for monoclonal antibody production but have largely been replaced by CHO cells.

- Human embryonic kidney (HEK293) cells: HEK293 cells are an approved human cell line that produces specific recombinant proteins and viral vectors for gene therapies

- PER.C6 cells: A human embryonic retinal cell line that produces biotherapeutics, including adeno-associated viral vectors for gene therapies.

While mammalian cell lines like CHO are preferred for producing complex glycoproteins due to human-like glycosylation patterns, non-mammalian sources offer advantages like higher yields, lower costs, and reduced risk of viral contamination. Examples of non-mammalian cell lines are:

- Yeast cell lines, such as Pichia pastoris (Komagataella phaffii) and Saccharomyces cerevisiae.

- Insect cell lines, such as Sf9 and Sf21 (derived from Spodoptera frugiperda) and High Five (derived from Trichoplusia ni).

- Bacterial cell lines such as Escherichia coli.

- Nicotiana tabacum BY-2 is a tobacco cell line derived from the callus culture of Nicotiana Tabacum L. cv. Bright Yellow 2.

The Importance Of Cell Culture In Manufacturing

In upstream bioprocessing, cells are cultured in an optimized, controlled environment designed to produce consistent, scalable, and reproducible yields of the target biologic.

Overview Of Cell Culture Techniques

Standard cell culture techniques include:

- Suspension culture: Cells are grown in liquid media, allowing for easier scale-up in bioreactors.

- Adherent culture: Cells grow attached to surfaces, often used for viral vaccine production.

- Fed-batch culture: Nutrients are added during the culture process to extend production time.

- Perfusion culture: Continuous addition of fresh media and removal of spent media, allowing for very high cell densities.

- Single-use bioreactors: Disposable culture vessels that reduce contamination risk.

Key Factors Influencing Cell Line Development

Cell line development uses transfection or transduction, the two standard techniques that introduce genetic material (such as DNA or RNA) into host cells to produce biopharmaceuticals. Both methods are essential for introducing genes that encode biopharmaceutical products into host cells, enabling the cells to produce the desired proteins for further downstream processing.

Transfection Techniques And Their Impact On Cell Line Stability

Transfection introduces foreign genetic material into cells to create stable cell lines that express specific proteins or therapeutic molecules. It is commonly used in mammalian cell culture systems, such as CHO cells, to produce recombinant proteins and monoclonal antibodies.

The transfection methodologies described below have advantages and limitations regarding efficiency, cytotoxicity, payload capacity, and ease of use. The choice depends on the specific cell type, the nature of the nucleic acid cargo, and the experimental requirements.

Chemical Transfection

Chemical transfection utilizes compounds like calcium phosphate or cationic polymers to form negatively charged nucleic acid complexes. These complexes can then bind to the cell membrane and enter the cell via endocytosis.

For example, calcium phosphate precipitation is a cost-effective method where a calcium phosphate-DNA precipitate forms and adheres to the cell surface for uptake. Also, cationic polymers like polyethyleneimine or DEAE-dextran form positively charged complexes with nucleic acids, facilitating their cell entry.

Electroporation

Electroporation is a physical method that uses brief electric pulses to create temporary pores in the cell membrane. This allows nucleic acids to enter the cytoplasm directly. It is highly efficient for many cell types, including hard-to-transfect cells like primary and stem cells.

Lipofection

Lipofection, also known as cationic lipid transfection, involves synthetic cationic lipids that form liposomes capable of complexing with nucleic acids. These lipid-nucleic acid complexes can fuse with the cell membrane and release their cargo into the cytoplasm. It is a versatile method suitable for various cell types and nucleic acid payloads.

Nucleofection

Nucleofection is a proprietary electroporation-based technique developed by Lonza. It combines the principles of electroporation with cell-type-specific nucleofection solutions. This optimized system facilitates the direct transfer of nucleic acids into the nucleus, resulting in high transfection efficiencies, especially for difficult-to-transfect cells like primary cells and stem cells.

Cell Line Transduction

Similarly to transfection, transduction introduces genetic material into cultured cell lines but uses viral vectors, most commonly lentiviral vectors. It is a powerful technique for generating stable cell lines that express a gene of interest or for modulating gene expression.

The choice of transduction method depends on factors such as the target cell type, desired expression duration (transient or stable), packaging capacity requirements, and biosafety considerations.

Retroviral Transduction

Retroviral transduction introduces genetic material into target cells using vectors derived from retroviruses like the Moloney murine leukemia virus. It produces replication-defective retroviral particles by co-transfecting packaging cells with plasmids encoding the viral structural proteins and the gene of interest.

The retroviral particles can then transduce and integrate the gene into the host cell genome, leading to stable long-term expression. However, retroviral vectors can only transduce actively dividing cells as they require the nuclear membrane breakdown during mitosis for integration.

Lentiviral Transduction

Lentiviral transduction utilizes lentiviral vectors derived from the human immunodeficiency virus to deliver genetic material into dividing and non-dividing cells. Lentiviral particles are produced by co-transfecting packaging cells with plasmids encoding the viral proteins, envelope protein (e.g., VSV-G), and the transfer vector containing the gene of interest.

Lentiviral vectors can transduce and integrate into the genomes of dividing and non-dividing cells, including stem and primary cells. They have a larger packaging capacity than other viral vectors.

Adenoviral Transduction

Adenoviral transduction involves using adenoviral vectors, which are non-integrating viruses, to deliver genetic material into target cells. Adenoviral vectors can transduce both dividing and non-dividing cells with high efficiency. They remain episomal without integrating into the host genome, leading to transient gene expression.

AAV Transduction

AAV (adeno-associated virus) transduction utilizes AAV vectors, which are non-pathogenic parvoviruses, to deliver genetic material into target cells. AAV vectors can transduce both dividing and non-dividing cells, including stem cells and post-mitotic cells like neurons. They can integrate into the host genome at a specific site (AAVS1 locus) or remain episomal, leading to long-term gene expression.

Genetic, Environmental, And Technical Factors

The genetic, environmental, and technical parameters discussed below must be fully optimized in upstream bioprocessing to produce high-yielding, stable cell lines for biologics.

Genetic Factors

The goal of cell line development is to produce a target gene of interest for biopharmaceutical applications, and several genetic factors affect expression:

- Host cell line: Different cell lines have varying capabilities for protein production and post-translational modifications.

- Gene optimization: Genetic engineering techniques such as codon optimization enhance the gene of interest’s expression.

- Vector design: The design of the expression vector, including promoter choice and regulatory elements, impacts gene expression levels.

- Integration site: The genomic location where the transgene integrates affects expression stability and levels. Site-specific integration can help control this.

- Copy number: The number of copies of the transgene that integrate into the genome also influences expression.

Environmental Factors

The cells’ environment affects their growth, yield, and efficacy, including:

- Culture media composition: The nutrients and supplements in the growth media significantly impact cell growth and protein production.

- Culture conditions: Temperature, pH, dissolved oxygen, and osmolality must be optimized.

- Scale-up considerations: Conditions may need to be adjusted when transitioning from small-scale to bioreactor production.

Technical Factors

- Transfection method: The transfection technique affects how efficiently the gene is delivered.

- Selection strategy: A vigorous selection strategy to identify high-producing clones is critical.

- Single-cell cloning: Monoclonal populations must be isolated to establish stable cell lines.

- High-throughput screening: Large numbers of clones must be rapidly evaluated to improve the chances of identifying top producers.

- Analytics: Robust assays assess product quality, titer, and cell line stability throughout development.

Optimizing The Workflow In Cell Line Development

Although cell line development is a complex process, biopharmaceutical manufacturers can reduce timelines and improve efficiency by adopting the following strategies:

Automation And High-Throughput Screening

Automating liquid handling systems and robotics accelerates cell culture and screening tasks, while high-throughput screening platforms rapidly evaluate large numbers of clones. Additionally, automated imaging systems enhance clone selection and growth monitoring.

Optimize Vector And Host Cell Engineering

Optimizing expression vectors with strong promoters and enhancers, engineering host cell lines for improved growth, productivity, and product quality, and employing site-specific integration techniques for more predictable gene expression all work together to improve cell line development.

Improve Clone Selection Strategies

Darly-stage metabolite analysis can identify high-producing clones faster. Also, miniaturized bioreactors provide earlier evaluation of clone performance while advanced analytics like metabolomics enrich clone characterization.

Streamline Processes

Wherever possible, manufacturers should implement parallel processing, optimize media and feed strategies early in development, and use predictive modeling to guide process development decisions.

Leverage Advanced Technologies

Single-cell printing/sorting technologies improve clonality assurance, while genome editing tools like CRISPR provide targeted cell line engineering. Companies should also utilize advanced analytics and data management systems for maximum efficiency.

Enhance Data Management And Analysis

Implement data analytics and machine learning for clone selection and establish robust data management practices for regulatory compliance.

What Factors Influence Cell Line Productivity?

Cell lines are stable when they can maintain consistent characteristics over time. Ensuring cell line stability involves monitoring genetic, phenotypic, and productivity changes over multiple generations and involves the following factors.

Media And Feeds: Their Role In Cell Line Productivity

- Cell lines can have different nutritional requirements and growth characteristics, even if derived from the same parent line. Optimizing media composition and feed strategies is crucial for maximizing productivity and product quality.

- Multi-omics analysis combines proteomics and metabolomics data, providing insights into the cell phenotype and helping design optimized media formulations tailored to the specific cell line.

- Appropriate nutrient feed strategies are based on real-time monitoring of nutrients, metabolites, and bioprocess parameters, improving substrate levels and preventing nutrient limitations or accumulation of inhibitory byproducts.

Optimizing Bioreactor Conditions For Enhanced Output

- Maintaining consistent environmental conditions, such as pH, temperature, dissolved oxygen, and carbon dioxide levels across scales, is critical for achieving similar cell growth, productivity, and product quality.

- Key parameters, such as impeller tip speed, volumetric gas flow rate, power input per unit volume, and mass transfer coefficient, need to be optimized to ensure adequate mixing and gas transfer and minimize shear stress.

- Strategies like micro-sparging and precise pore membrane cell retention devices may be required to handle high cell densities and maintain ideal dissolved oxygen levels during scale-up.

Process Intensification

Process intensification yields higher cell densities and increases productivity. Strategies such as N-1 perfusion and intensified fed-batch cultures enable higher seeding densities in production bioreactors with exponentially increased titers. Cell lines must be engineered to withstand intensified conditions, e.g., glutamine synthetase knockout in CHO cells. The goal of process intensification is to achieve higher volumetric productivity while maintaining product quality.

Monitoring Titer Levels For Efficient Protein Production

Systematically monitoring protein titer levels provides critical data to make informed decisions throughout the cell line development process and allows manufacturers to select highly productive and stable clones by doing the following:

- Identifying high-producing clones early: Measuring titer levels early and often during the cell line development process allows manufacturers to quickly identify the clones producing the highest levels of the desired protein and focus resources on expanding and characterizing the most promising candidates.

- Optimizing culture conditions: Monitoring titers over time and under different cultures provides data to optimize media formulations, feeding strategies, and other parameters to maximize protein production. This iterative process can substantially boost overall yields.

- Gaining insights into clone stability: Tracking titer levels over extended culture periods and multiple passages provides information on protein expression stability in different clones. This helps select clones that maintain high productivity over time.

- Guiding cell line engineering efforts: Titer data can reveal bottlenecks in protein production and guide targeted genetic engineering approaches to enhance productivity further.

- Making informed scale-up decisions: Understanding titer profiles at a small scale helps predict performance in larger bioreactors and informs process development decisions.

- Assessing product quality early: Along with titer, early analysis of protein quality attributes from different clones aids in selecting cell lines that produce protein with the desired characteristics.

- Reducing timelines and costs: By quickly identifying top performers and optimizing conditions, overall cell line development timelines and costs can be significantly reduced.

- Supporting regulatory filings: Comprehensive titer data throughout development provides essential information for regulatory submissions.

Scale-up Considerations And Strategies

- Bioreactor geometry, impeller design, and gassing strategies can impact cell growth, viability, and product quality during scale-up, necessitating scale-down models and bioreactor characterization.

- Computational tools and scaling algorithms are employed to determine the appropriate operating parameters (agitation, gas flow rates) across scales while maintaining consistent mixing, mass transfer, and shear profiles.

- A quality-by-design approach involving multi-parameter optimization and characterization at smaller scales is recommended to identify the "design space" and facilitate seamless scale-up while meeting product quality targets.

- Pilot-scale runs are essential for troubleshooting and fine-tuning process parameters before committing to large-scale manufacturing, as issues with product quality are more challenging and costly to resolve at larger scales.

Types Of Cell Lines And Their Applications

CHO cells remain dominant in biopharmaceutical manufacturing due to their long safety record and high productivity, but HEK293 and other human cell lines are gaining popularity, especially for proteins requiring human-like modifications or for viral vector production. The ideal cell line depends on the specific product and process requirements.

Characteristics Of Mammalian Cell Lines In Biopharmaceuticals

Mammalian cell lines are used to develop and reproduce the target protein. While CHO cells are the most widely used, other cell lines are gaining popularity.

CHO Cells

Due to their high productivity, robust growth, well-characterized glycosylation patterns, and long regulatory track record, CHOs remain the most popular cell line. Engineered variants such as CHO-K1, CHO-S, and CHO-DG44, are also available.

HEK293 (Human Embryonic Kidney) Cells

HEK293 cells are human-derived, providing high transfection efficiency. They grow rapidly, are easy to culture, and produce human-like post-translational modifications. HEK293 are often used for transient and stable protein expression and are increasingly used in viral vector production. Engineered variants include HEK293T, HEK293F, and HEK293-6E.

Other Notable Mammalian Cell Lines

Depending on the target protein, other mammalian cell lines may be used, including:

- NS0 and SP2/0 (murine myeloma cells)

- BHK (Baby Hamster Kidney)

- PER.C6 (human retinal cells)

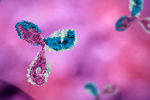

CHO Cell Lines: The Preferred Choice For Therapeutic Production

Remarkably, about 70% of all recombinant proteins are produced using CHO cells. Their popularity stems from their versatility, productivity, and ability to produce proteins with human-like post-translational modifications. In particular, CHO cells can perform human-like post-translational modifications, especially glycosylation, which is crucial for proper protein folding and function.

CHO cells are also highly productive and scalable to commercial levels. At the same time, they carry a lower risk of viral contamination than human cell lines. These cells also provide genetic stability, providing consistent protein production. Notably, CHO cells can grow in serum-free suspension cultures, which is cost-effective for large-scale manufacturing. Finally, CHO cells have a proven track record of regulatory approval.

CHO Cell Line Applications

CHO cell lines are used in many applications, including:

- Monoclonal antibodies for treating diseases like cancer, multiple sclerosis, asthma, and HIV.

- Recombinant proteins, such as enzymes and hormones.

- Bispecific antibodies, including complex antibody formats like bispecific antibodies.

- Cell line development, i.e., transfection, protein production, purification, and expression optimization.

- Process optimization like perfusion culture strategies for enhanced antibody production.

Comparing CHO And HEK293 Cell Lines For Protein Production

When drug developers choose between CHO and HEK293 cells, they consider the specific protein being produced and its requirements for post-translational modifications and functionality.

While CHO cells offer the many benefits described above, HEK293 cells have some advantages over CHO cells. First, since they are human cells, they can produce human post-translational modifications and are easier to transfect than CHO cells. They are also better suited to perform γ-carboxylation and tyrosine sulfation. HEK293 cells grow quickly in suspension and serum-free media while providing complex, human-like glycosylation patterns. They are often used for research, early-stage development, and some specific therapies.

Key Differences Between CHO And HEK293

- Post-translational modifications: HEK293 cells provide more human-like modifications, which can be crucial for some proteins.

- Safety concerns: CHO cells pose lower biosafety risks due to their non-human origin.

- Regulatory track record: CHO cells have a more established regulatory history for biopharmaceuticals.

- Protein-specific advantages: Some proteins perform better in HEK293 cells, while others are more suited to CHO cells.

- Scale-up: CHO cells are generally preferred for large-scale production, though HEK293 cells are improving in this area.

Ensuring A Stable Cell Line

Stable cell lines are necessary to develop the target proteins that create safe, viable, and highly effective biopharmaceutical therapy products.

How To Develop A Stable Cell Line

Precise engineering, single-cell sorting, and viability optimization allow manufacturers to develop stable cell lines that consistently produce high-quality biopharmaceutical products with improved efficiency and regulatory compliance.

- Host cell line selection: Choosing an appropriate host cell line, such as CHO cells, is the first step in ensuring stability.

- Vector engineering: The expression vector must be meticulously designed to include strong promoters, enhancers, and regulatory elements promoting the desired protein's high-level expression.

- Transfection and selection: The engineered vector is introduced into host cells via transfection or transduction.

- Cloning and expansion: Single-cell cloning establishes monoclonal cell lines and safeguards genetic homogeneity and stability.

- Screening and characterization: Clones are rigorously screened for high productivity, growth rate, and product quality. Cell viability, protein expression level, and genetic stability are also assessed.

Importance Of Single-Cell Sorting

Single-cell sorting ensures the following:

- Monoclonality: The cell line originates from a single cell for genetic uniformity.

- High-throughput screening: Advanced cell sorting technologies rapidly identify high-producing clones from a large population.

- Purity: Mixed populations are eliminated, reducing the risk of low-producing cells overtaking the culture over time.

- Regulatory compliance: Clonal derivation demonstration is often required for regulatory approval.

Strategies For Achieving High Viability In Stable Cell Lines

Manufacturers should adopt the following practices to maintain that stable cell lines are also highly viable:

- Optimize culture conditions: Optimize media composition, temperature, pH, and oxygen levels to support cell growth and productivity.

- Implement fed-batch or perfusion cultures: Select strategies that extend culture duration and maintain high cell viability.

- Monitor and control metabolite levels: Regularly assess and adjust glucose, lactate, and ammonia concentrations to prevent metabolic stress.

- Use anti-apoptotic strategies: Incorporate genetic modifications or media supplements that inhibit apoptosis and promote cell survival.

- Maintain low passage numbers: Regularly thaw fresh vials of cells to avoid genetic drift and maintain consistent performance.

- Optimize cell density: Maintain appropriate cell densities to prevent contact inhibition and nutrient depletion.

- Quality control: Implement rigorous measures to detect and prevent contamination or cross-contamination.

Best Practices For Screening And Transfection

Cell lines must maintain consistent characteristics over time, particularly regarding expressing the desired biopharmaceutical product. Ensuring cell line stability involves monitoring the cell line for genetic, phenotypic, and productivity changes over multiple generations.

Genetic Stability

Genetic stability occurs when the introduced gene or genes in the cell line appear without significant changes or mutations. Genetic stability is monitored using PCRs, sequencing, and Southern blotting techniques, as described in the Genetic Characterization section above.

Phenotype Stability

Phenotypic stability refers to the consistency of the cell line's characteristics, such as growth rate, morphology, and protein expression profile, over time. Changes in these characteristics can affect the productivity and quality of the biopharmaceutical product. Phenotype stability is monitored and controlled by:

- Growth Rate

- Growth kinetics, such as doubling time, specific growth rate (μ), and maximum cell density, are routinely tracked across passages/generations.

- Significant deviations in growth rates can indicate phenotypic drift or instability.

- Morphology

- Regular microscopic observation is performed to detect changes in cell size, shape, granularity, or abnormalities.

- Altered morphology may signal underlying genetic/epigenetic changes impacting productivity.

- Protein Expression Profile

- Techniques like ELISA, Western blotting, and protein analytics (glycosylation, charge variants) monitor product titer, quality attributes, and impurities.

- Consistent protein expression levels and critical quality attributes demonstrate a stable production phenotype.

To maintain phenotypic stability, cell lines undergo rigorous characterization and analysis at multiple stages:

- During clone screening and selection, only clones exhibiting stable growth, viability, productivity, and product quality are advanced.

- At the MCB stage, the selected production clone is extensively characterized to establish a reference phenotype.

- The phenotype is continuously monitored during culture scale-up by analyzing growth, productivity, and product quality.

- At the EOP stage, the phenotype is compared to the MCB reference to verify stability.

- Bioprocess parameters like media, pH, temperature, and dissolved oxygen are carefully controlled to minimize phenotypic drift.

If phenotypic changes are detected, techniques like cell sorting, recloning, or regeneration from an earlier cell bank may be employed to recover the desired stable phenotype.

Productivity Stability

Productivity stability is the cell line's consistent target protein production over multiple generations. Monitoring productivity stability involves measuring the expression levels of the target protein and ensuring they remain within acceptable limits.

Measuring Expression Levels Of The Target Protein

A comprehensive picture of target protein expression can be obtained by integrating data from multiple analytical techniques across different molecular levels (transcripts, proteins, metabolites). This enables the optimization of bioprocess parameters and timely interventions to maintain stable, high-level productivity of the desired biotherapeutic protein throughout manufacturing. To measure and monitor the expression levels of the target protein during bioprocessing to ensure productivity stability, manufacturers can choose from several methods.

Fluorescence Monitoring

A dicistronic construct is used where the target protein gene is coupled to a fluorescent reporter gene like mCherry or GFP. The fluorescence intensity, measured by spectrofluorometry or fluorescence microscopy, correlates with the expression level of the target protein. This allows real-time, non-invasive monitoring of target protein expression during fermentation.

Analytical Protein Assays

ELISA is commonly used to quantify the titer or concentration of the target protein in culture supernatants. Other techniques, such as SDS-PAGE and Western blotting, provide protein size, purity, and relative expression level information.

Product Quality Analysis

Analytical methods like chromatography (HPLC, SEC), mass spectrometry, or glycan analysis are used to characterize critical quality attributes of the target protein. Monitoring post-translational modifications, charge variants, aggregation levels, etc., ensures consistent product quality.

Transcriptomics/Proteomics

RNA sequencing can detect changes in transcript levels of the target gene and host cell genes related to protein synthesis. Ribosome profiling provides insights into the translational landscape, while proteomics techniques identify and quantify proteins synthesized under different bioprocess conditions.

In-Process Monitoring

Techniques like in-situ turbidity and Raman/NIR spectroscopy allow monitoring of biomass and nutrient levels related to productivity. Metabolic flux analysis tracks intracellular metabolic fluxes impacting protein synthesis.

Keeping Expression Levels Within Acceptable Limits

Integrating data from multiple analytical techniques across molecular levels (transcripts, proteins, metabolites) with bioprocess monitoring and control can maintain expression levels within the desired range throughout production. When deviations are detected, timely interventions like media/feed adjustments or parameter changes are made.

Additional methods to monitor and maintain expression levels of the target protein within acceptable limits during bioprocessing include:

- Bioprocess Monitoring And Control: Real-time monitoring of critical bioprocess parameters like nutrients (glucose, amino acids), metabolites (lactate, ammonia), dissolved oxygen, pH, etc., using analytical techniques like Raman/NIR spectroscopy, biosensors, etc., enables optimal control of conditions for target protein expression.

- Metabolic Flux Analysis: Tracking intracellular metabolic fluxes through techniques like 13C metabolic flux analysis provides insights into pathways impacting protein synthesis and productivity.

- Feeding Strategies: Appropriate nutrient feed strategies based on real-time data are employed to maintain ideal substrate levels and prevent nutrient limitations or accumulation of inhibitory byproducts that can negatively impact expression.

Selection Pressure

Cell lines are often subjected to selection pressure during the cloning and screening process, which can lead to the emergence of high-producing clones. However, this can also result in the loss of genetic stability and the accumulation of mutations. Careful management of selection pressure is necessary to maintain cell line stability, but it carries risks.

Loss Of Genetic Stability

High-producing clones are often generated through gene amplification systems like methotrexate or glutamine synthetase, which impose intense selection pressure. This can lead to genetic instabilities like rearrangements, deletions, or silencing of the amplified genes over time in culture. Phenotypic drift and loss of productivity are commonly observed in such high-producing clones due to the accumulation of mutations or epigenetic changes.

Clonal Variation And Heterogeneity

Even clones derived from a single-cell progenitor can exhibit significant phenotypic heterogeneity and variability in productivity. This heterogeneity arises from the dynamic population dynamics and shifting expression patterns in clonal cell populations over generations. Due to this inherent variability, identifying and maintaining the highest producers becomes challenging.

Prolonged Timelines

Generating high producers often requires multiple rounds of transfection, screening, and subcloning, which is labor-intensive and time-consuming (up to a year). Accelerating timelines using pools instead of clones can compromise productivity, stability, and product quality attributes.

Tradeoffs In Productivity Vs. Product Quality

Strategies to boost productivity, like gene amplification, can sometimes negatively impact critical quality attributes like glycosylation patterns. There may be tradeoffs between maximizing titer and maintaining desired product quality profiles.

Analytical Challenges

High-throughput screening of large numbers of clones for productivity and product quality is analytically demanding. Integrating multi-omics data (genomics, transcriptomics, proteomics, metabolomics) is required for in-depth clone characterization.

Cryopreservation Techniques

Cell lines are often cryopreserved at various stages of development to ensure their long-term storage and availability. Proper cryopreservation techniques are essential to maintain cell line stability during storage and revival. Slow freezing and vitrification are commonly used techniques that each have their advantages and disadvantages.

Slow Freezing

Slow freezing involves gradually cooling cells at a controlled rate (typically 0.5-2°C/min) in the presence of cryoprotective agents (CPAs) like dimethyl sulfoxide (DMSO) or glycerol. The controlled cooling rate allows cells to dehydrate gradually, avoiding intracellular ice formation, which is lethal. CPAs penetrate cells and help protect against freezing injury by reducing the amount of ice formed.

Slow freezing is suitable for preserving cell clusters/clumps and adherent cells and is a relatively simple and scalable process compared to vitrification. However, it can still cause sublethal damage, such as membrane disruption and osmotic stress.

Vitrification

Vitrification rapidly cools cells (>1000°C/min) in highly concentrated CPAs to solidify them into a glass-like state without forming ice crystals, avoiding crystal damage. Vitrification is suitable for cryopreserving individual cells, small cell clusters, and sensitive cell types and provides better post-thaw recovery and survival compared to slow freezing for some cell types.

However, the process requires high CPA concentrations (e.g., DMSO, ethylene glycol, sucrose), which can be cytotoxic. It is also technically challenging, requiring precise control of cooling/warming rates, and is less scalable than slow freezing.

Monitoring And Characterization

Regular monitoring and characterization of the cell line are essential to detect any changes in genetic stability, phenotypic characteristics, or productivity. This may involve regular genetic and phenotypic analysis and productivity assays.

Genetic Stability

Integrating data from genetic sequence analysis, gene expression studies, and cell bank characterization enables comprehensive monitoring of genetic stability throughout bioprocessing. This multi-pronged approach ensures product quality and consistency by identifying and addressing genetic drift early.

Cell Bank Characterization

The MCB and EOP cell banks undergo rigorous characterization to establish and verify genetic stability. Restriction endonuclease mapping and Southern blotting confirm the integrity of the transgene integration pattern in the host genome. Copy number determination of the integrated transgene is performed using quantitative PCR (qPCR).

Techniques like PCR or sequencing analyze the retention and stability of the recombinant construct over multiple passages. Karyotype analysis can detect extensive chromosomal abnormalities or rearrangements that may impact genetic stability. Comparing the genetic profiles of MCB and EOP cell banks allows the assessment of any genetic drift or instability accumulated during production.

Genetic Sequence Analysis

Sequencing technologies play a vital role in monitoring genetic sequence integrity. NGS enables complete genome sequencing to comprehensively analyze the transgene sequence, integration sites, and any mutations across the entire genome.

Targeted DNA sequencing of the transgene and surrounding regions can detect sequence variations or rearrangements. RNA sequencing of transcripts can identify mutations impacting gene expression. Sequence analysis at different stages (MCB, EOP) allows genetic alterations to be tracked over time.

Gene Expression Analysis

Techniques like RT-qPCR, Northern blotting, and RNA-seq quantify transcript levels of the transgene and host cell genes related to productivity. Ribosome profiling provides insights into the translational landscape and protein synthesis rates, while proteomics methods like mass spectrometry can detect alterations in protein expression profiles. Deviations in transgene expression levels or host cell protein expression patterns may indicate underlying genetic instabilities impacting productivity.

Phenotypic Characteristics

An integrated multi-analytical approach combining protein characterization, functional assays, and immunochemical analysis provides a comprehensive assessment of phenotypic characteristics and ensures the production of therapeutics with the intended critical quality attributes:

Protein Characterization

Protein characterization techniques monitor CQAs and product heterogeneity that can impact phenotype. Physicochemical properties like size, charge variants, and post-translational modifications (e.g., glycosylation) are analyzed using techniques like size-exclusion chromatography, ion-exchange chromatography, capillary electrophoresis, and mass spectrometry.

Spectroscopic methods like circular dichroism, Fourier-transform infrared spectroscopy, and intrinsic fluorescence evaluate higher-order structures (secondary, tertiary). Techniques like Edman degradation, peptide mapping, and mass spectrometry confirm amino acid sequence, primary structure, and modifications. SDS-PAGE, Western blotting, and analytical ultracentrifugation monitor purity, impurities, and aggregation levels. Deviations in these CQAs from the desired product profile can indicate phenotypic drift during production.

Functional Assays

Various cell-based functional assays are used to directly monitor the biological activity and mechanism of action of the therapeutic protein. For antibodies, antibody-dependent cell-mediated cytotoxicity and complement-dependent cytotoxicity measure effector functions. Binding assays like ELISA and surface plasmon resonance determine target antigens' binding affinity/avidity. Cell proliferation, apoptosis, migration, and other phenotypic readouts evaluate the functional impact on target cells. Changes in these functional characteristics can indicate underlying phenotypic alterations.

Immunochemical Properties

The immunochemical properties of antibodies, which define their phenotype, are characterized by:

- Binding kinetics and affinity measurements by surface plasmon resonance.

- Epitope mapping by techniques like hydrogen-deuterium exchange mass spectrometry.

- Cross-reactivity testing against related proteins/antigens.

- Assessing aggregation propensity by light scattering, size exclusion chromatography.

Monitoring these immunochemical parameters ensures the antibody retains its desired specificity and functionality.

Protective Stability

Formulation optimization, accelerated/real-time stability testing, and forced degradation studies are established approaches to understanding degradation mechanisms and ensuring the productive stability of therapeutic proteins during manufacturing and storage.

Clonal Selection And Cell Line Quality

Clonal selection is the process of isolating and selecting individual cell clones that exhibit desirable characteristics for the production of biopharmaceuticals. This step is typically performed after cells' initial transfection or transduction with the gene of interest. It aims to identify high-producing and stable cell lines for further development and scale-up.

The Role Of Clonal Selection In Therapeutic Protein Production

The clonal selection process often involves a multi-tier screening approach. Clones are initially evaluated for productivity, followed by stability and monoclonality assessments. The most promising clones meeting all three criteria are advanced for scale-up, process development, and manufacturing.

Productivity

Effective clones produce high levels of the desired therapeutic protein or antibody. Clonal productivity is typically measured by assessing the titer or concentration of the product in the culture supernatant. High productivity is essential for achieving economically viable yields during bioprocessing and is determined by the following factors:

- Specific productivity rate (amount of product produced per cell per unit time).

- Volumetric productivity (total product yield per unit volume of culture).

- Growth characteristics (maximum cell density, viability, growth kinetics).

Clones with high specific and volumetric productivity and desirable growth profiles are selected.

Stability

The clone must be stable to maintain consistent productivity and growth characteristics over extended periods of culturation and across multiple generations. Stable clones are crucial for ensuring reproducible and reliable bioprocessing and are defined as maintaining:

- Genetic stability (preservation of the transgene and consistent expression levels).

- Phenotypic stability (consistent growth, viability, and productivity profiles).

- Resistance to environmental stresses (pH, osmolality, shear forces).

Clones exhibiting stable transgene expression, consistent productivity, and robustness under bioprocessing conditions are ideal for bioprocessing.

Monoclonality

Monoclonality refers to the clonal purity of the cell line, ensuring that all cells within the population are derived from a single progenitor cell. Monoclonal cell lines are essential for consistent product quality and regulatory compliance and are assessed by techniques such as:

- Single-cell cloning (limiting dilution or flow cytometry-based sorting).

- Molecular analysis (PCR, Southern blotting, karyotyping).

- Protein analysis (isoelectric focusing, mass spectrometry).

Clones confirmed to be monoclonal, with a single integration site and consistent product quality, are chosen for selection and further characterization.

Determining Clonal Selection Outcomes

Throughout the clonal selection process, rigorous quality control measures are implemented to ensure the selected cell line's integrity, traceability, and regulatory compliance. The clonal selection process for identifying high-producing cell lines involves the following methodologies.

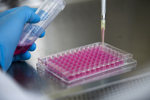

Single Cell Dilution

Single-cell or limiting dilution cloning isolates individual cells and establishes clonal cell lines from a heterogeneous population. First, the cell suspension is diluted to extremely low densities, ensuring that each well of a multi-well plate contains either zero or one cell. Next, the single cells proliferate, forming distinct colonies or clones. Finally, the clones are screened for the desired characteristics (e.g., productivity, stability). This process ensures monoclonality.

Cell Culture And Expansion

Once single-cell-derived clones are isolated, they undergo cell culture and expansion to generate sufficient biomass for further characterization and screening. Typically, this involves culturing the clones in specialized growth media under controlled conditions (e.g., temperature, pH, and oxygen levels).

The cell cultures are also carefully monitored and maintained during scale-up to larger volumes or bioreactors and checked for growth kinetics, viability, and productivity at different scales. Successful clones must maintain stable growth and productivity characteristics during expansion.

Primary Screening

Primary screening is the initial evaluation of a large number of clones to identify the most promising candidates based on specific criteria:

- Productivity: assessing the titer or yield of the desired product (e.g., antibody, recombinant protein).

- Growth characteristics: evaluating cell density, viability, and growth kinetics.

- Gene copy number: determining the number of transgene integrations.

High-throughput analytical techniques like ELISA, flow cytometry, and qPCR are often employed for primary screening.

Secondary Screening

Secondary screening involves a more comprehensive characterization of the top clones identified from primary screening. Genetic stability is assessed through gene expression analysis and karyotyping, while phenotypic stability is evaluated by monitoring productivity and growth over multiple generations. Monoclonality is confirmed via techniques like single-cell sorting and molecular analysis. Finally, product quality attributes (e.g., glycosylation patterns and charge variants) are closely evaluated.

The most promising clones that meet all the desired criteria are then selected for further process development and manufacturing.

Cell Banking

Cell banking enables consistent and reliable bioprocessing operations, ensuring the safety and efficacy of biopharmaceutical products and cell-based therapies.

What Are The Best Practices For Cell Banking?

The following issues are crucial to establishing safe, effective, and compliant cell banks:

Establishment Of Master And Working Cell Banks

Establishing well-characterized and cryopreserved MCBs and Working Cell Banks (WCBs) ensures reproducibility, consistency, and traceability in bioprocessing applications. MCBs are the originating source for generating WCBs, which are used for routine cell culture operations and manufacturing processes.

Biosafety And Contamination Control

Maintaining the integrity and purity of cell banks is paramount to preventing contamination by adventitious agents such as bacteria, fungi, mycoplasma, or viruses. Strict aseptic techniques, cleanroom environments, and rigorous testing for sterility, identity, and genetic stability are essential to ensuring cell banks' biosafety in bioprocessing applications.

Regulatory Guidelines and Requirements

Cell banking processes must adhere to stringent regulatory guidelines and requirements, such as GMP and ICH, FDA, and EMA guidelines. These guidelines ensure cell banks' safety, quality, and traceability in producing biologics, vaccines, and cell-based therapies.

Characterization

Characterization involves a series of tests and analyses to assess the properties of the cell line and the expression system used for producing biopharmaceuticals. This step ensures the final product's quality, safety, and efficacy.

Genetic Characterization

Genetic characterization is a crucial aspect of bioprocessing cell line development to ensure the production cell lines' genetic stability, identity, and integrity. These assessments are conducted at critical stages, such as the Master Cell Bank (MCB) and End-of-Production (EOP) cells, to demonstrate the genetic stability and integrity of the production cell line throughout the bioprocessing lifecycle. Rigorous genetic characterization ensures consistent product quality, safety, and regulatory compliance. Here are the essential methods used for genetic characterization:

PCR (Polymerase Chain Reaction)

PCR is a widely used technique for amplifying and detecting specific DNA sequences in cell lines by confirming the presence and copy number of the transgene encoding the therapeutic protein. PCR also verifies the integration site(s) and detects mutations in the transgene in the host cell genome. Quantitative PCR (qPCR) is helpful for accurate copy number determination and monitoring transgene stability across different cell passages or production stages.

Sequencing

DNA sequencing is a powerful tool for comprehensive genetic characterization of cell lines. It verifies the nucleotide sequence of the transgene construct, identifies potential mutations or variations in the transgene or host genome, confirms the integrity of the transgene integration site(s), and analyzes the genomic context surrounding the integration site(s).

Next-generation sequencing (NGS) technologies, such as whole-genome sequencing (WGS) and targeted sequencing, also provide high-resolution and in-depth characterization of cell line genomes.

Southern Blotting

Southern blotting is a traditional technique that involves separating DNA fragments by gel electrophoresis, transferring them to a membrane, and probing with labeled DNA probes specific to the transgene or genomic regions of interest. This technique determines the copy number of the integrated transgene, analyzes the integration pattern (single or multiple integration sites), and detects potential rearrangements or deletions in the transgene or host genome.

While labor-intensive, Southern blotting remains a valuable method for genetic characterization, particularly in combination with other techniques like PCR and sequencing.

Protein Expression

Optimizing protein expression in genetically engineered cell lines is the foundation for cost-effective, large-scale production of safe and efficacious biopharmaceuticals that meet regulatory standards. Commonly used methodologies include:

ELISA (Enzyme-Linked Immunosorbent Assay)

ELISA is a widely used analytical technique for detecting and quantifying proteins in various samples. ELISA quantifies the expression levels of a specific protein by measuring its concentration in cell lysates or culture supernatants. It also monitors changes in protein expression levels under different experimental conditions or treatments and screens for the presence or absence of a target protein in many samples.

ELISAs rely on antibodies' specific binding to the target protein. The signal generated (e.g., colorimetric, fluorescent) is proportional to the protein present, allowing for quantitative measurements.

Western Blotting

Western blotting is a semi-quantitative technique for analyzing protein expression. Proteins are separated based on their molecular weight and detected via specific antibodies. This confirms the presence and size of a specific protein in a sample and estimates relative expression levels by comparing band intensities across different samples or conditions. Additionally, Western blotting detects post-translational modifications or proteolytic processing events that alter protein size and validate antibodies' specificity in other protein expression assays.

While not as quantitative as ELISA, Western blotting provides valuable information about protein size, isoforms, and modifications, complementing other protein expression analysis methods.

Mass Spectrometry

Mass spectrometry (MS) is a powerful analytical technique for comprehensive protein expression analysis. MS identifies and quantifies proteins in a sample through peptide mass fingerprinting or sequencing, detecting post-translational modifications, splice variants, and mutations that alter protein sequence or mass. Additionally, it is used to perform relative or absolute quantification of protein expression levels across different samples or conditions. MS also analyzes protein-protein interactions and complexes through affinity purification and MS-based identification.

MS-based proteomics approaches, such as targeted or data-independent acquisition (DIA) methods, offer high sensitivity, specificity, and multiplexing capabilities for protein expression studies. However, they require specialized instrumentation, expertise, and bioinformatics support.

Product Quality Attributes

In cell line development, strategizing product quality attributes ensures safety and efficacy, regulatory compliance, consistency and comparability, process monitoring and control, and product characterization. Post-translational Modifications (PTMs), glycosylation, and structural integrity are carefully maintained through complex processes, detailed below.

Post-translational Modifications

PTMs are introduced and maintained through the action of various enzymes:

Conversely, enzymes like phosphatases, deacetylases, and deubiquitinases remove PTMs. This dynamic addition and removal of PTMs regulate protein function, localization, and stability.

Glycosylation Patterns

Maintaining desired glycosylation patterns on therapeutic proteins is crucial and achieved through:

- Host cell line selection: Mammalian cells like CHO, NS0, and HEK293 are preferred as they can perform human-compatible glycosylation.

- Media optimization: the composition of the culture media (glucose, amino acids, nutrients) is optimized to promote the desired glycosylation.

- Bioprocess monitoring: Glycosylation is routinely analyzed using HPLC, mass spectrometry, and lectin assays during upstream/downstream processing.

- Genetic engineering: Overexpressing or knocking down specific glycosyltransferases can tailor glycan structures.

- In vitro enzymatic modification: Using enzymes like galactosidases and sialyltransferases to modify glycan structures post-production.

Structural Integrity

Preserving the structural integrity and stability of therapeutic proteins involves:

- Optimizing expression conditions: Controlling temperature, pH, oxygen levels, and shear forces during cell culture to promote proper folding and minimize aggregation.

- Protein stabilization: using excipients, stabilizers (sugars, amino acids), and specialized formulations to stabilize proteins during purification and storage.

- Monitoring degradation: Techniques like size-exclusion chromatography, light scattering, and spectroscopy detect and quantify aggregates, fragments, and conformational changes.

- Process optimization: Optimizing pH, temperature, and buffer conditions to minimize chemical degradation (deamidation, oxidation) and physical instability.

- Genetic engineering: Introducing stabilizing mutations or fusion domains can enhance intrinsic protein stability.

Cell Growth And Viability

Rigorous monitoring and analysis of the following cell growth characteristics across different stages allow comprehensive characterization of cell proliferation, viability, and productivity:

- Cell count / cell density: Monitoring the increase in total cell number or cell density over time is a direct measure of cell proliferation and growth kinetics, whether manually using a hemocytometer or automatically via specialized equipment.

- Growth curve / growth phases: Analyzing the lag, log/exponential, stationary, and decline of the growth phase to assess its curve shape and kinetics, providing insights into proliferation rates and viability.

- Cell viability: Assessing the percentage of viable cells using standard methodologies such as trypan blue exclusion assays, fluorescent dyes that stain live/dead cells (e.g., calcein-AM, propidium iodide), and metabolic activity assays (e.g., MTT, resazurin reduction).

- Morphology: Regularly performing microscopic observation of cell morphology to reveal signs of stress, abnormalities, or contamination that impact growth and viability.

- Doubling time / specific growth rate: Calculate the population doubling time or specific growth rate (μ) during the exponential phase to obtain a quantitative measure of proliferation kinetics.

- Apoptosis / cell death: Monitoring apoptotic markers (e.g., caspase activity, annexin V binding) and cell lysis, which can indicate a loss of viability and productivity.

Metabolic Activity

Characterization may also include calculating the metabolic activity of the cell line through nutrient consumption, waste production, and energy metabolism to optimize the culture conditions for maximum productivity. Methods for tracking metabolic activity include:

- Metabolomics Analysis: Metabolomics, particularly mass spectrometry-based metabolomics, is widely employed to comprehensively profile the metabolic state of cells during different growth phases (exponential, stationary, decline). This allows tracking key metabolic pathways like glycolysis, pentose phosphate pathway, and the TCA cycle, as well as metabolite levels of nucleotides, amino acids, lipids, and energy molecules.

- Metabolic Flux Analysis: Techniques like 13C analysis provide quantitative insights into intracellular metabolic fluxes and pathway utilization by tracking the fate of 13C-labeled nutrient tracers to identify metabolic bottlenecks and optimize nutrient feeds.

- Gene Expression Analysis: Transcriptomic techniques like RNA sequencing and ribosome profiling are used to study changes in gene expression and translation related to metabolic pathways under different bioprocess conditions. This links cellular metabolism to its genetic regulators.

- Biomarker identification: Specific metabolites or metabolic signatures can be biomarkers to monitor and predict cellular metabolism and productivity during cell line development.

- Analytical assays: Measuring key metabolites like glucose, lactate, ammonia, amino acids, etc., in culture supernatants provides insights into central carbon metabolism. Techniques like the MTT assay track metabolic activity more broadly.

- Monitoring cell growth/viability: Parameters like cell density, viability, morphology, etc., routinely monitored during bioprocessing, serve as indirect indicators of cells' metabolic state and productivity.

Integrating data from these multi-omics approaches (metabolomics, transcriptomics, fluxomics) enables a comprehensive systems-level understanding of cellular metabolism. This knowledge guides media optimization, bioprocess control strategies, and metabolic engineering efforts to develop high-producing cell lines.

Contaminant Testing

Routine testing at multiple stages (seed stock, master cell bank, end-of-production cells) using the methods below is critical for ensuring contaminant-free, traceable, and regulatory-compliant cell lines.

Microbial Contamination

- Direct observation: Gross contamination can sometimes be detected visually by turbidity, color changes, or microbial growth in the culture medium.

- Culture-based testing: A small cell culture sample is inoculated into sterile growth media and incubated to allow the growth of any bacteria or fungi present. Turbidity in the test broths indicates contamination.

- Staining and microscopy: Staining with dyes like Gram stain followed by microscopic examination can identify bacterial or fungal morphologies.

Mycoplasma Contamination

- Culture techniques: Specialized mycoplasma broth and agar selectively grow and detect these bacteria that lack a cell wall.

- DNA staining: Fluorescent dyes, like Hoechst stain, that bind to mycoplasma DNA can reveal contamination under a fluorescence microscope.

- PCR or ELISA-based assays: Highly sensitive molecular techniques to detect mycoplasma nucleic acids or antigens.

Viral Contamination

- Cytopathic effects: Some viruses cause visible changes in cell morphology or viability, which can indicate contamination.

- Antibody production: Testing for antibodies against specific viruses in the culture supernatant.

- PCR or RT-PCR: Detecting viral nucleic acids by PCR amplification.

Cross-Contamination

- Isoenzyme analysis: Detecting differences in isoenzyme patterns between species.

- HLA typing: Human leukocyte antigen analysis for intra-species cross-contamination.

- DNA fingerprinting: STR (short tandem repeat) profiling to identify unique DNA fingerprints of different cell lines.

Regulatory Considerations

Regulatory agencies like the FDA, ICH, and EMA have strict requirements for bioprocess characterization and validation studies to ensure the safety, efficacy, and consistent quality of biopharmaceutical products. Current good manufacturing practices (cGMP) must be demonstrated and maintained throughout the cell line development process.

What Are The Key Considerations For Regulatory Compliance?

By addressing the following regulatory concerns and meeting the expectations for process characterization, biopharmaceutical manufacturers can demonstrate their ability to produce high-quality products and consistently gain regulatory approval for commercialization.

Demonstrating Process Understanding

Regulators emphasize the need for a comprehensive understanding of the manufacturing process, including identifying critical process parameters (CPPs), critical material attributes (CMAs), and their impact on critical quality attributes (CQAs) of the product, involving:

- Identifying potential CPPs and CMAs through risk assessments and filtering methods.

- Conducting studies (e.g., Design of Experiments) to determine the effects and interactions of CPPs and CMAs on CQAs.

- Developing mechanistic or statistical models enhances process understanding and establishes the design space.

Establishing A Robust Control Strategy

Regulators expect manufacturers to implement a robust control strategy based on understanding the process gained during characterization studies, including:

- Defining proven acceptable ranges and normal operating ranges for CPPs and CMAs.

- Justifying manufacturing operating ranges and acceptance criteria for CQAs.

- Implement appropriate control measures, such as in-process monitoring and control systems, to ensure process performance and product quality.

Scale-down Model Qualification

For bioprocesses, regulators require the qualification of scale-down models used for characterization studies to demonstrate their representativeness of the commercial manufacturing scale, such as:

- Comparing data from commercial-scale runs with data from scale-down models at set-point conditions.

- Statistically demonstrating the similarity between scales using appropriate statistical methods (e.g., TOST tests).

Data Integrity And Traceability

Regulators stress the importance of data integrity, traceability, and proper documentation throughout the characterization studies:

- Collecting and organizing data from various sources (upstream, downstream, quality, small-scale, manufacturing scale, etc.).

- Implementing strategies for data contextualization, handling complex data types (time-series, multivariate, etc.), and data management.

- Confirming data traceability and maintaining comprehensive records of all characterization activities.

Regulatory Concerns

Manufacturers must demonstrate comprehensive understanding and control over the production cell line, culture conditions, and manufacturing process to ensure a robust, consistent, and validated system for commercial-scale manufacturing of a safe and productive biopharmaceutical product in the following areas:

Cell Line Characterization And Documentation

Regulatory agencies require comprehensive characterization and documentation of the production cell line, including its origin, genetic modifications, banked cell lineage, and testing to ensure it is free of adventitious agents. Manufacturers must prove clonality and sustained genetic stability over an extended period.

Expression Vector Design

The design of the expression vector used for transfection is critical. It must contain the appropriate genetic elements to drive efficient and stable therapeutic protein expression in the host cell line. Regulatory bodies evaluate the vector for potential safety risks, such as undesirable sequences.

Transfection And Cloning Process

Manufacturers must provide details on the transfection method and cloning process to isolate the production cell line. Clonality verification by methods like cell imaging is required to demonstrate the production cell line originated from a single cell.

Tumorigenicity Assessment

Regulators may require tumorigenicity testing in relevant animal models for cell lines of tumorigenic origin to evaluate any potential safety risks, especially for products with direct patient exposure.

Adventitious Agent Testing

The clone screening and selection process must include controls and procedures to prevent adventitious agent contamination, such as viruses or other contaminants. Detailed information on the steps taken to maintain sterility and avoid cross-contamination during colony picking and expansion is required.

High-Throughput Screening Capability

Automated high-throughput screening platforms can increase the probability of identifying rare, high-producing clones and provide consistent, well-documented results. Regulatory agencies evaluate the suitability and validation of these systems.

Process Optimization And Scale-Up

Cell culture conditions (media, feed strategies, process parameters) are developed at a small scale to achieve the desired product quality attributes and productivity. As the process is scaled up, manufacturers must ensure consistent product quality and yield by maintaining similar environmental conditions (pH, dissolved oxygen, shear stress) across scales.

Critical Process Parameters

Critical process parameters like bioreactor operating conditions (agitation, aeration, pH, temperature), media components, and feeding strategies that impact critical quality attributes must be identified, controlled, and monitored during scale-up. Strategies like high-throughput screening may be used.

Comparability Studies

Regulatory bodies require extensive comparability studies demonstrating consistency in product quality attributes between scales and across multiple production batches. This includes analytical testing and biological characterization.

Manufacturing Process Control

Manufacturers must implement robust process controls, in-process testing, and monitoring strategies to ensure process consistency and product quality during scale-up. Detailed documentation on process development, equipment/facility qualification, and

Conclusion And Summary

Cell line development is a critical first step in bioprocessing therapeutic proteins and other biologics. Selecting a suitable cell line requires careful evaluation of various factors to ensure the successful production of biopharmaceutical products. Establishing a robust, high-yielding cell line requires a multifaceted approach combining molecular biology techniques, bioprocess optimization, analytical testing, and quality control measures.

Looking ahead, continued innovation in cell line development will be essential for meeting the growing demand for biologics and bringing new modalities like gene therapies to market. Companies investing in this critical capability will be well-positioned to develop and manufacture the next generation of life-changing biologics efficiently.

Emerging Trends And Advancements In Cell Line Development

The future of cell line development for biopharmaceutical production holds several promising trends and advancements:

Continuous Manufacturing

Continuous manufacturing promises to improve efficiency by evaluating multiple parameters in one run. This reduces human intervention and operational costs while creating smaller footprints with the flexibility to match market demand and accelerate tech transfer from pilot to commercial scale. While challenges remain, the biopharmaceutical industry is increasingly exploring continuous manufacturing, driven by its potential for higher quality, lower costs, and shorter timelines.

Early Clone Identification And Screening

A growing focus is on implementing high-throughput screening technologies like NGS, omics analysis, and optofluidics to identify and characterize high-producing clones earlier in the cell line development workflow. This allows faster parallel screening of thousands of clones to select those with optimal productivity, genetic stability, and desired product quality attributes upfront, reducing late-stage failures.

Automation And Closed Systems

Cell line development is moving towards more automated and closed systems for transfection, single-cell cloning, and clone expansion to increase efficiency, robustness, and consistency. Automated platforms with minimal manual handling steps can accelerate timelines while ensuring sterility and reproducibility.

Genetic Engineering Approaches

Emerging technologies like CRISPR/Cas9 genome editing, targeted integration systems, and inducible expression systems are being applied to engineer optimized production cell lines. This includes modifying host cells to improve product quality, increase titers, reduce metabolic burden, or enable the expression of complex proteins like bispecifics.

Computational Tools And Machine Learning

There is increased adoption of computational tools, bioinformatics, and machine learning algorithms to guide cell line engineering strategies, predict high producers, and gain deeper insights into factors influencing productivity and product quality.

Continuous Monitoring And Control

Advanced analytical tools enabling real-time monitoring of critical process parameters and product quality attributes during cell culture are being implemented to understand better and control production processes.

Alternative Production Platforms

While CHO cells remain dominant, alternative production hosts like human cell lines are being explored. These could offer advantages like more human-like glycosylation patterns and reduced immunogenicity for specific products.

Overall, the future of cell line development is focused on increasing speed, efficiency, product quality, and manufacturability through the integration of cutting-edge technologies, automation, computational approaches, and host cell engineering.

Process Intensification And Sustainability

The trend towards process intensification can help manufacturers meet their sustainability goals. For instance, continuous manufacturing, perfusion technologies, and smaller facility footprints enable higher cell densities and productivity while redoing waste and lowering energy consumption. Advanced control and monitoring technologies optimize continuous processes and improve efficiency. Meanwhile, the industry is also developing circular economies for raw materials and consumables with the goal of carbon-neutral manufacturing.

Common Pitfalls And How To Avoid Them

With careful planning, advanced technology, and best practices, biopharmaceutical manufacturers can significantly improve the efficiency and success rate of their cell line development processes.

Genetic Instability

- Pitfall: Loss of transgene expression or genomic rearrangements over time.

- Avoidance: Implement rigorous genetic stability testing, use site-specific integration techniques, and optimize selection methods.

Low Productivity

- Pitfall: Selecting clones with poor protein expression levels.

- Avoidance: Employ high-throughput screening methods, use predictive modeling, and optimize expression vectors.

Contamination

- Pitfall: Microbial contamination leading to loss of cell lines.

- Avoidance: Maintain strict aseptic techniques, regularly test for contaminants, and implement robust quality control measures.

Phenotypic Drift

- Pitfall: Changes in cell behavior or productivity over time.

- Avoidance: Minimize passage numbers, regularly thaw fresh vials, and implement comprehensive characterization protocols.

Poor Scalability

- Pitfall: Clones that perform well in small-scale cultures fail in large-scale production.

- Avoidance: Evaluate clones in conditions that mimic large-scale production early in development.

Inadequate Documentation

- Pitfall: Insufficient records leading to regulatory issues.

- Avoidance: Implement robust documentation systems and adhere to cGMP guidelines throughout development.

Selection Bias

- Pitfall: Choosing clones based on limited criteria, leading to suboptimal cell lines.

- Avoidance: Use multi-parameter analysis for clone selection and maintain a diverse pool of candidates.

Media Optimization Challenges

- Pitfall: Suboptimal growth conditions affecting productivity and quality.

- Avoidance: Implement systematic media optimization strategies and use chemically defined media when possible.

Frequently Asked Questions (FAQs)

Below are some frequently asked questions regarding cell line development.

1. What is cell line development?

Cell line development creates stable, high-producing cell lines for manufacturing biopharmaceuticals like monoclonal antibodies and recombinant proteins. It involves selecting host cells, engineering expression vectors, transfection, cloning, and screening to identify optimal clones for large-scale production.

2. Why are cell lines important in biologics manufacturing?

Cell lines are crucial in biologics manufacturing because they:

- Provide a consistent source for producing complex proteins

- Enable large-scale production of biopharmaceuticals

- Ensure product quality and consistency across batches

- Allow for cost-effective and efficient manufacturing processes

3. What is the process of cell line development?

The key steps in cell line development are:

- Host cell line selection

- Expression vector engineering

- Transfection

- Single-cell cloning and expansion

- Screening and selection of high-producing clones

- Cell banking and characterization

4. How do CHO cells differ from HEK293 cells in protein production?

CHO cells:

- Industry standard for antibody production

- Robust growth in suspension culture

- Produce human-like glycosylation patterns

HEK293 cells:

- Better for producing human proteins

- Faster growth and protein expression

- More human-like post-translational modifications

CHO cells are preferred for large-scale antibody production, while HEK293 cells are often used for research and early-stage development.

About The Author

Elizabeth Mann is a skilled writer with over a decade of experience in content creation, specializing in the life sciences industry. As a writer for Life Science Connect, she develops in-depth content that informs and engages professionals in the pharmaceutical, biotech, and medical device sectors. Her areas of focus include biologic drug production (including cell and gene therapies), clinical trial design and execution, and drug development and manufacturing outsourcing.

EXPERT INSIGHTS ON CELL LINE DEVELOPMENT

-