ABOUT CARR BIOSYSTEMS

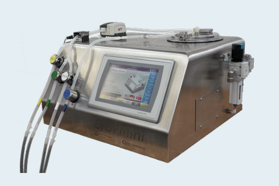

With over three decades of pioneering versatile stainless steel and single-use separation systems, CARR Biosystems delivers high-performance, fully-scalable bioprocessing solutions to accelerate process development. We help scientists and engineers produce vital biologics in emerging and established markets, including cell and gene therapy, vaccine development, microbial fermentation, and cellular agriculture.

OUR PRODUCTS

CONTACT INFORMATION

CARR Biosystems

14550 58th St N

Clearwater, FL 33760

UNITED STATES

Phone: 727.287.9400

Contact: Dave Johnson

FEATURED ARTICLES

-

Discover how N-1 intensification shortens production timelines and improves cell viability by replacing traditional filtration with automated, low-shear separation techniques to achieve higher seeding densities.

-

Learn how optimizing clarification workflows can reduce product loss and minimize buffer consumption by shifting primary workloads away from traditional high-capacity depth filtration systems.

-

Discover how automating cell banking workflows minimizes contamination risks and preserves viability in high-density cultures, ensuring consistent recovery and smoother scale-up.

-

A study demonstrates how a low-shear, closed-system centrifuge achieved over 90% MSC recovery and minimized viability loss, supporting scalable cell therapy manufacturing.

-

Low-shear, closed-system media exchange in iPSC differentiation is vital for scalability. This study compares automated centrifugation to gravity sedimentation, showing equivalent or superior differentiation outcomes.

-

In cell processing, rigid, single-function equipment can lead to inefficiencies, wasted space, and scheduling conflicts. A versatile approach can help teams do more with less.

-

Discover how new processing methods tackle challenges in large-scale stem cell production and how automated, low-shear processing maintains cell health and pluripotency across production scales.

-

Discover common pitfalls in cell washing and pre-formulation, including incomplete contaminant removal, manual handling, and throughput issues that compromise product quality and efficiency.

-

Current cell harvest techniques in allogeneic manufacturing face limitations, including scalability issues and cell damage. Learn why a shift in approach is vital for high-quality, efficient production at scale.

-

Traditional depth filtration struggles with lentiviral harvest clarification, leading to low yields and high costs. However, single-use centrifugation offers a promising alternative.

WEBINARS AND VIDEO

-

Scale-up often introduces shear stress and process variability. Learn how low-shear, single-use technology stabilizes media exchange and harvest, ensuring consistent cell quality and predictable performance.