Process Analytical Technology For In-line Bioprocess Analysis: MAVERICK

This easy-to-use process analytical technology device offers in-line bioprocess analysis and control with no complex modeling. Measure multiple critical parameters across media, across processes, across mammalian cell lines, across scales.

All In-line Gain, No Modeling Pain

MAVERICK is powered by Raman spectroscopy and a purpose-built de novo model. The de novo model is explicitly built on media chemistries and device physics, not on empirical data. It automatically interprets the spectra and quantifies process parameters enabling simultaneous measurements of glucose, lactate, and total biomass. This is achieved without the costs, complexities, and risks associated with conventional Process Analytical Technology (PAT) methods. There is no need to grapple with complex empirical models, reagents, or unreliable auto-sampling systems to implement in-line bioprocess analysis.

How the De Novo Model Works

The MAVERICK measurements are based on a de novo model. This model was developed from first principles without empirical observation/calibration in bioprocesses with any particular media. The de novo model considers both static and dynamic parameters measured during the actual bioprocess runs. One of the static parameters is a formulary which includes the spectral characteristics of many chemical components in media. These include glucose, lactate, and other cell culture media components detectable by Raman. The dynamic parameters include adapting to changes in environmental factors such as ambient light, temperature, and turbidity, including cell based fluorescence. It also accounts for the characteristics of each unique device from an optical, electronic, and measurement error model perspective.

The MAVERICK measurements are based on a de novo model. This model was developed from first principles without empirical observation/calibration in bioprocesses with any particular media. The de novo model considers both static and dynamic parameters measured during the actual bioprocess runs. One of the static parameters is a formulary which includes the spectral characteristics of many chemical components in media. These include glucose, lactate, and other cell culture media components detectable by Raman. The dynamic parameters include adapting to changes in environmental factors such as ambient light, temperature, and turbidity, including cell based fluorescence. It also accounts for the characteristics of each unique device from an optical, electronic, and measurement error model perspective.

Real-time Analysis in Minutes

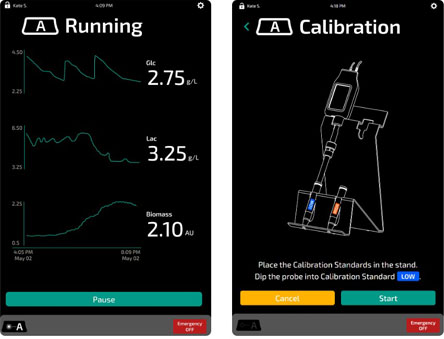

Measure critical bioprocess parameters now, not in weeks or months. No bioprocess runs to collect Raman spectra. No modeling required. There’s an easier way–with MAVERICK’s purpose-built de novo model. Get actionable process parameters in three easy steps: calibrate, autoclave, and start your bioprocess run.

Process Analytical Technology (PAT) Made Easy

While in-line process analytical technology (PAT) offers many benefits, adoption has been hindered by technical challenges, integration issues, and significant implementation costs.

MAVERICK addresses all these issues, ushering in an era of accessible, continuous monitoring of multiple parameters. With MAVERICK, your team can stay at the forefront of Bioprocessing 4.0 and fully harness the advantages of real-time in-line bioprocess analysis (bioreactor monitoring) and control. Intuitive setup and user-friendly interface means there is no training barrier to overcome.

MAVERICK – Easy to Learn, Easy to Use

MAVERICK – Easy to Learn, Easy to Use

MAVERICK is intuitively designed for ease of use, requiring no prior experience with Raman spectroscopy or chemometric modeling. It features a user-friendly hub with a high-resolution color touchscreen, CFR 21 Part 11 compliant software, and an intuitive interface that simplifies in-line bioprocess analysis. With MAVERICK, mastering bioprocess monitoring is straightforward and efficient.

Instant Raman, Ready in Minutes

MAVERICK offers all the advantages of Raman-based process analytical technology (PAT) without the cost and complexities associated with developing “black box” empirical calibration models, required by conventional process spectroscopy-based methods. While it can take months and a dedicated team of experts to build and validate a robust empirical calibration model—MAVERICK only takes a simple two-point probe calibration to begin monitoring multiple key process parameters in most types of bioreactors. Just take it out of the box, and you’re already halfway through the setup process.

Already Have Raman Implemented & Having Trouble?

MAVERICK removes the need to maintain models and simply works across processes, scales, devices, and probes. Because it is a commercial off-the-shelf system (COTS), it allows for easy measurement method validation, unlike complex empirical models. Experience a cost-effective solution with little to no device maintenance. MAVERICK delivers a robust and scalable Process Analytical Technology (PAT) solution that helps advance your bioprocess through the pipeline to commercialization.

Multiplex Flex

Connect up to six measurement modules to a single MAVERICK hub to monitor process conditions and control feeds across multiple bioreactors independently and simultaneously in real-time. This setup saves valuable bench space and boosts efficiency.