ABOUT W.L. GORE & ASSOCIATES, INC.

In a highly regulated industry marked by economic pressures and drug development and processing challenges, Gore provides technology-driven products and process components designed for efficiency, reliability and contamination control.

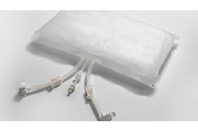

Single-use GORE® STA-PURE™ Flexible Freeze Containers are intended for storing and transporting bulk drug substances after freezing at -86°C (-123°F).

Single-use storage containers have many advantages to biopharmaceutical manufacturers and are commonly used throughout drug production. However, there are vulnerabilities associated with traditional polymer-film-based disposable bags:

- They can become brittle and fragile at cold temperatures, increasing the risk of loss during cold chain handling, transport or storage.

- Extractables and leachables from materials commonly used in disposable packaging are a concern.

NOW, GORE MATERIALS SCIENCE DELIVERS A SOLUTION TO BOTH ISSUES

Single-use GORE STA-PURE Flexible Freeze Containers are intended for storing and transporting bulk drug substances, after freezing at -86°C (-123°F).

The strength, durability and high purity of the materials of construction make GORE STA-PURE Flexible Freeze Containers ideal for high-value biopharmaceutical bulk drug substances such as:

- vaccines

- monoclonal antibodies

- antibody drug conjugates (ADCs)

- And a robust validation package and available technical support are offered to make initial evaluation easier

Utilizing our advanced materials understanding, we’ve engineered a highly durable proprietary fluropolymer (PTFE) composite film designed specifically for bulk biopharmaceutical cold chain applications.

GORE STA-PURE Flexible Freeze Containers are sold as an assembly and are suitable for both plate and blast freezers in sample, small, medium and large sizes. Maximum fill volumes vary by freezing method. Contact us for tubing and connector options.

Introducing the GORE® STA-PURE® Flexible Freeze Container Stability Bag

W.L. Gore & Associates, Inc.’s PharmBIO division is excited to announce the launch of the GORE® STA-PURE® Flexible Freeze Container Stability Bag. The stability bag is a product line extension to the GORE STA-PURE Flexible Freeze Container intended for handling, transport and storage of biopharmaceutical intermediates after freezing at temperatures as low as -86 C. The 50 mL container can be supplied with Luer Lock connectors for easy under hood filling. Colder AseptiQuik® S connectors for aseptic filling of small volumes are also available to support stability testing, phase 1-3 clinical testing or sampling during GMP production. The stability bag is constructed using the same proprietary 100% fluoropolymer PTFE film as our GORE STA-PURE Flexible Freeze Container product line. Supplied inside two Tyvek® pouches, the stability bag is sterile certified and ready to use. For more information, visit our website to review the GORE STA-PURE Flexible Freeze Container datasheet.

GORE STA-PURE Flexible Freeze Containers have proven strength and durability at frozen temperatures and maintain integrity after multiple freeze/thaw cycles. If the risk of product loss due to container breakages or leaks are a concern throughout your cold chain, you can contact a Gore associate today for more information or samples of the GORE STA-PURE Flexible Freeze Container product line.

VIDEOS

-

Learn how the GORE® STA-PURE® Flexible Freeze Container may help minimize the risk of product loss when storing and transporting bulk drug substances at low temperatures.

-

Single-use GORE® STA-PURE® Flexible Freeze Containers are intended for storing and transporting bulk drug substances, particularly at temperatures down to -80°C (-112°F).

-

How many containers are you willing to lose? This animated video demonstrates how the GORE® STA-PURE® Flexible Freeze Container helps minimize the risk of product loss in the cold chain.

CONTACT INFORMATION

W.L. Gore & Associates

402 Vieve's Way

Elkton, MD 21921

UNITED STATES

Phone: 410-506-5510

Contact: Joe Cintavey

PRODUCTS

-

See how the 50-milliliter (ml) stability container assembly supports handling, transport and storage of biopharmaceutical intermediates, after freezing at -86°C (-123°F).

-

Specially fitted disposable Hard-shell Carriers, suitable for plate or blast freezers, are available as accessories. They are designed to maximize freezer space, make handling easier and further protect tubing in the Container Assembly.

-

Discover single-use flexible containers intended for the handling, transport, and storage of frozen bulk drug substances that resist cracks, breaks, or leaks if accidentally dropped.

FEATURED ARTICLES

-

While barrier films in bags can be useful for cold chain applications, they do not fully protect against gas ingress and ignore other sources of permeability.

-

With each batch of cell and gene therapy product representing a wealth of lifesaving potential, this biopharma company needed the right packaging solution for its relatively new therapy applications.

-

Learn more about a flexible freeze container that maintains package integrity after freezing at -86 °C (-123 °F) through its durable design, minimizing product loss due to package failure.

-

Although polymer bags are an excellent choice for cold chain use, not all polymer films perform the same way, even if their specifications rate them for use at low temperatures.

-

Learn about new materials being considered for single-use cold chain storage containers to reduce or eliminate issues with durability at cold temperatures.

-

Explore how to develop a strong packaging system, and learn more about why a reliable supply chain is critical for drug substance and drug product transport.

-

Demands for flexible, scalable, cost effective manufacturing are prompting cell and gene therapy manufacturers and CDMOs to implement single-use technology for manufacturing their therapies.

-

Drug manufacturers seek packaging that maintains integrity during processing and freezing, scales up to larger volumes easily, and remains robust throughout the temperature-controlled supply chain.

-

See why single-use cold-chain containers made with polytetrafluoroethylene fluoropolymers may be less susceptible to failure and breakage at cold temperatures.

-

Packaging is critical, as biotechnology products requiring colder storage become more valuable. Find out how you can improve your temperature-controlled supply chain and meet cold chain storage demands.