Update On The Adoption Of Advanced Rapid Microbiology Methods In Biopharma

By Matthew Pillar, Editor, Bioprocess Online

A BioPhorum survey of biopharmaceutical end-users representing 11 companies reveals the big opportunity—and the key challenges—involved in the adoption of advanced rapid microbiology methods.

This fall, a group of 18 BioPhorum members comprised of executives from biopharma firms and the vendor/supplier community collaborated on a comprehensive survey-based project exploring next-generation methods for the detection of bacteria and viruses in bioprocess samples. BioProcess Online queried three authors of the resulting paper for a Q&A highlighting the findings published in the BioPhorum paper, Rapid Detection Of Bacteria And Viruses In Bioprocess Samples: Justification, Regulation, Requirements And Technologies — How Can Industry Achieve Broad Adoption?

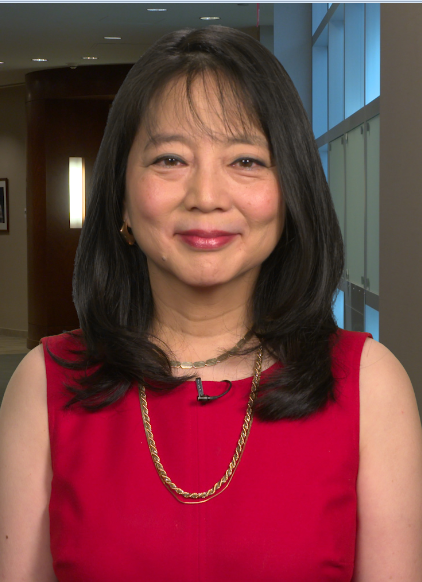

Participating in our Q&A were Audrey Chang, global head of development services at BioReliance Merck; Morven McAlister, senior director at Pall Biotech; and Scott Hooper, associate director at Merck & Co Inc. Kenilworth, NJ.

The trio provided an overview of industry’s progress in its adoption of advanced rapid microbiology methods (ARMM) to detect the presence of bacteria, mycoplasma and viruses in days, rather than the weeks required of traditional approaches.

Those traditional approaches to microbial detection are based on plate culture techniques developed in the late 1800’s—today’s compendial methods still rely heavily on growth based techniques for sterility testing. Alternative approaches to RMM have been in development since the early 2000’s, and while these techniques use different markers to indicate the presence of microorganisms, they all share a common end goal: to reduce the time required for results compared to conventional culture-based methods.

BioProcess Online: What was the impetus for conducting the survey and developing the resulting paper? What specific issues/challenges did it seek to address?

Chang: A primary goal for today’s biopharmaceutical company is the development and production of safe and effective products. As scientific advances are driving the evolution of next-generation manufacturing platforms, scientific advances are also providing new methods to test for unwanted microbial and viral contamination. These alternative methods can produce faster results (days vs weeks), and can potentially offer the same or even better sensitivity and range than their current counterparts. Methods such as next generation sequencing, PCRs, and rapid sterility platforms exist today, yet many of us are still releasing products using 28-day cell-based viral assays, 28-day mycoplasma assay, and 14-day sterility assays.

Chang: A primary goal for today’s biopharmaceutical company is the development and production of safe and effective products. As scientific advances are driving the evolution of next-generation manufacturing platforms, scientific advances are also providing new methods to test for unwanted microbial and viral contamination. These alternative methods can produce faster results (days vs weeks), and can potentially offer the same or even better sensitivity and range than their current counterparts. Methods such as next generation sequencing, PCRs, and rapid sterility platforms exist today, yet many of us are still releasing products using 28-day cell-based viral assays, 28-day mycoplasma assay, and 14-day sterility assays.

McAlister: The survey was intended to gather input from a broad range of end-users covering different job functions to try and understand why the biopharmaceutical industry is not using ARMMs more widely. Even though 50 percent of respondents stated that time to obtain results was the biggest source of dissatisfaction, it was not deemed of sufficient concern to change from current compendial to ARMMs. The survey revealed that this was because of either real or perceived regulatory hurdles associated with either implementation of ARMM for a new process, or doing a regulatory filing as change control of an existing process.

McAlister: The survey was intended to gather input from a broad range of end-users covering different job functions to try and understand why the biopharmaceutical industry is not using ARMMs more widely. Even though 50 percent of respondents stated that time to obtain results was the biggest source of dissatisfaction, it was not deemed of sufficient concern to change from current compendial to ARMMs. The survey revealed that this was because of either real or perceived regulatory hurdles associated with either implementation of ARMM for a new process, or doing a regulatory filing as change control of an existing process.

Hooper: The survey allowed the team to develop a broad view of the current state and gaps involved in adventitious agent and sterility testing. Through this broader viewpoint we were able to summarize the needs of the field and to outline methods and strategies for bridging from the current state to filling those needs.

Hooper: The survey allowed the team to develop a broad view of the current state and gaps involved in adventitious agent and sterility testing. Through this broader viewpoint we were able to summarize the needs of the field and to outline methods and strategies for bridging from the current state to filling those needs.

BioProcess Online: Frame up why this survey-based assessment is important.

Chang: Our group is focused on how to facilitate the adoption and implantation of rapid testing methods for viral and microbial biosafety assessment. We seek to understand the technical and regulatory perspective from our manufacturing colleagues. The industry survey on both topics, viral and microbial, provides clarity on the barriers that prevent us from adopting these methods.

McAlister: The effort showed that provision of a guidance document that enables sharing of best validation practices within the industry and includes regulatory involvement would have the greatest impact on widespread industry adoption of ARMM.

Hooper: The promise of ARMM is being held back due to a variety of barriers. Understanding and naming those challenges and barriers allows development of strategies for mitigating them.

BioProcess Online: What are the unique attributes/requirements of advanced therapy medicinal products (ATMPs) that pose challenges to the current paradigm?

Chang: ATMPs are a new class of biological products that have tremendous clinical promise. ATMPs differ from traditional biologics in that they have limited biological shelf lives, they’re made in small batches, there’s a speed to market urgency, and they meet previously unmet needs for patients. These factors make them unsuitable for assays that take weeks to complete. As they are a new product class, we see an opportunity for regulatory agencies and industry to work together to lay a foundation of biosafety assessment guidance documents purpose-built for ATMPs.

McAlister: In addition to potentially small batch sizes and short shelf lives, the environment in which the treatment may be administered to the patient creates a challenge for using current compendial methods on ATMPs. Further, smaller start-up companies involved with novel ATMP development may not have the resources or experience to validate ARMM for ATMPs. Therefore, provision of a playbook into best practices will help ensure the safety of lifesaving medicines.

Hooper: ATMPs in fact represent an opportunity for shifting the current paradigm toward implementation of ARMMs. Since the shelf-life, patient need and/or volumes of ATMPs do not fit the classical microbiology method model, they eliminate regulatory inertia and provide a compelling rationale for employing innovative methodologies.

BioProcess Online: Why aren’t current microbial detection methods applicable to continuous bioprocessing?

Chang: Current methods are based on batch processing, or testing at the end of the run, where the likelihood of detecting a contaminant is the greatest. Continuous bioprocessing, by definition, will have multiple points of assessments that will differ from platform to platform. ARMM can facilitate both process development and lot release assessments.

McAlister: While current detection methods can work, they delay the time for results either for process monitoring or sterility testing for product release. Further, because continuous bioprocesses may run for days, weeks, or even months, it is critical that the sterility of the process fluid be monitored throughout production. To fully reap the benefits of continuous bioprocessing, implementation of ARMMs is appropriate.

Hooper: The multi-day detection time required of classic microbiological detection methods results in a significant risk to the production process. This is particularly acute for a continuous process, since by the time a contamination is detected, a significant amount of product and potentially a significant portion of the equipment could be contaminated. For this reason, ARMMs are being employed to ensure, on a real-time or near-real-time basis, that the process steps remain under microbiological control.

BioProcess Online: Please summarize the most important or interesting findings from the survey. Were there any noteworthy surprises?

Chang: We expected that the primary point of dissatisfaction with current methods was time to result. It was surprising that it was overwhelmingly the #1 choice (90 percent for viral, 60 percent for microbial respondents). The difference in these percentages is reflective of the fact there are ARMMs for bacteria and mycoplasma but few ARMMs for virus detection.

McAlister: I was surprised that 60 percent of the respondents stated they outsource their testing. Outsourcing testing may make it more difficult for the end users to consider moving to ARMMs, potentially due to lack of internal resources to support this.

Hooper: It is also noteworthy that the top three impediments to the implementation of ARMMs are not technical, but rather acceptance-based concerns (regulatory acceptance, burden of regulatory change control, and burden of validation proof).

BioProcess Online: Why is it the case that regulatory acceptance is such a hurdle to the adoption of ARMM?

Chang: From a regulators’ perspectives, there are no specific regulatory hurdles, but a lack of experience from both industry and regulators with how to navigate implementing these new assays.

McAlister: Because there is not one gold standard to follow, end users adopt different ways of attempting to validate and implement ARMMs. This means from a regulatory perspective, there is no consistency is what they are provided to review, which leads to a lot of back-and-forth discussion. In addition, there may also be the feeling that maintaining the status quo for testing will not lead to delays caused by regulatory scrutiny, resulting in one less hurdle to overcome in getting a drug to market.

Hooper: There are two primary aspects to regulatory acceptance being the top hurdle to adoption in the survey. Most obvious is an agency’s decision of whether or not to adopt. The other, more inertia-setting aspect is the fear that a technology will not be accepted by a regulator.

BioProcess Online: What is the current state of regulatory engagement in ARMM development/adoption? Aren’t regulators part of the dialogue?

Chang: The agencies have seen ARMM methods for product release testing, in particular mycoplasma qPCR and rapid bacterial methods, but these represent the exception and it’s taken years to get to this state. Part of the expectation is that agencies are particularly attentive to the validation package presented, comparability studies with compendial methods, definition of method sensitivity and background, and typically the bar is set higher for the new methods. Currently, the agencies see individual validation packages on a case-by-case basis that can differ from one to the next, which precludes the development of best practices.

McAlister: Through the activities of this BioPhorum group, it was clear from the start that regulatory engagement was critical for success. In phase 1, we reached out to get feedback from the agencies on the survey findings, and what we considered to be logical next steps to facilitate adoption of ARMMs by end users. Most importantly, in Phase 2, the ultimate goal is to develop a best practice guideline for validating and implementing ARMMs. This will only be successful if we have regulatory buy-in and address their concerns as we move through this exercise, such that the learnings can be shared with the industry.

Hooper: Written guidance by regulatory agencies encouraging the use of ARMMs has been published. The tactical details behind how to implement the ARMM, however, are points of discussion and concern. BioPhorum has approached both the U.S. FDA and a group of European national regulatory agencies to discuss the potential pathway(s) to implementation of ARMMs.

BioProcess Online: Aside from developing the paper, what else is BioPhorum doing to facilitate alignment between industry and regulators on validation studies?

Chang: Gold standards in term of validation packages exist, and regulatory agencies have seen these, but it is up to industry to make them public.

McAlister: The output of Phase 2 is to develop a best practices guideline on how to validate an ARMM. The focus for this activity is on mycoplasma and virus testing, and a case study will be shared for implementation of an ARMM for mycoplasma testing. The plan is to share this data with the regulatory agencies, and ultimately, come up with a document that will be aligned with regulatory expectations, as well as sharing the pitfalls encountered along the way.

Hooper: As mentioned above, a BioPhorum industry collaboration has held face to face meetings with both the U.S. FDA and European national regulatory agencies to discuss the implementation of Rapid Microbiological Methods.

BioProcess Online: What are the next steps – for BioPhorum, for regulators, and for our readers/industry?

Chang: We have identified a need to focus on ARMMs for virus and mycoplasma. We are asking the question: what features does an assay validation need to have, regardless of platform, for a manufacturer to release a product? The rapid method must detect a wide range of targets at a low detection limit that provides assurance of the product’s safety profile, which is ultimately paramount to patient safety.

By establishing a framework early on, it will allow the development of methods to include the principles outlined in our Rapid Viral Method Validation Framework Guidebook that will lay the foundation for performing an industry-wide collaborative multi-validation that can be used for regulatory submissions.

The group is not interested in promoting a specific biological molecule, manufacturing platform, testing method, or testing platform but rather providing guidance that aligns industry and regulatory expectations. We envision that our Guidebook will be the first paper to outline the situation and provide consensus on the multi-validation collaborative approach. By issuing the Guidebook, new innovative methods will incorporate the principles for the validation parameters early in design such that the methods are fit for purpose.

Representing the industry consensus, we desire to share our work at a face to face meeting with the regulatory agencies for feedback on our vision and provide input on our Framework Guidebook.

McAlister: Completion of Phase 2 in the agreed timeline will be an enormous task, so we have to stay focused on our deliverables. In addition, because this involves multiple BioPhorum members, it is anticipated that the final output will reflect a broad range of opinions and be a very robust document. However, by publicly talking about the work this group is doing, it is hoped that some of the current barriers, perceived or real, to implementation of ARMMs can be broken down.

Hooper: Continued engagement with regulatory bodies through multi-company consultations will accelerate acceptance on both sides of the discussion. While companies can and do engage individually, knowing that multiple companies have sought and gained agreement for one or more technologies will allay fears that an ARMM technology will not be accepted.

ABOUT BIOPHORUM

The BioPhorum Operations Group’s (BioPhorum’s) mission is to create environments where the global biopharmaceutical industry can collaborate and accelerate its rate of progress, for the benefit of all.

Since its inception in 2004, BioPhorum has become the open and trusted environment where senior leaders of the biopharmaceutical industry come together to openly share and discuss the emerging trends and challenges facing their industry.

Growing from an end-user group in 2008, BioPhorum now comprises 53 manufacturers and suppliers deploying their top 2,800 leaders and subject matter experts to work in seven focused Phorums, articulating the industry’s technology roadmap, defining the supply partner practices of the future, and developing and adopting best practices in drug substance, fill finish, process development and manufacturing IT. In each of these Phorums, BioPhorum facilitators bring leaders together to create future visions, mobilize teams of experts on the opportunities, create partnerships that enable change and provide the quickest route to implementation, so that the industry shares, learns and builds the best solutions together.