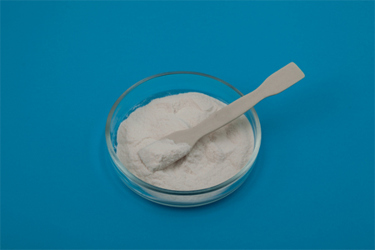

Rheological Properties Of Pharmaceutical Excipients: Lactose Monohydrate And Carboxymethyl Cellulose

By Behbood Abedi, PhD.

Powder rheology plays a critical role in the pharmaceutical industry for characterizing excipients and optimizing drug formulations. It examines the flow behavior and deformation of powders, directly influencing manufacturing processes and final product quality. The TA Instruments™ HR Powder Rheology Accessory enables comprehensive analysis by measuring flowability, compressibility, and shear under temperature-controlled conditions. This study focuses on lactose monohydrate and carboxymethyl cellulose (CMC), two widely used excipients, evaluating their flowability, cohesion, and compressibility to aid formulation optimization before scale-up.

Lactose monohydrate demonstrated over three times higher compression and cohesion values than CMC. Both excipients exhibited rate-dependent flow energy, decreasing as tip speed increased. Their rheological properties were assessed at 45 °C (to simulate sunlight exposure) and 4 °C (to simulate refrigeration). At 4 °C, lactose monohydrate shifted towards cohesive flow, indicating increased sensitivity to low temperatures.

The findings suggest that CMC flows better under high stress, whereas lactose monohydrate performs optimally under moderate to low stress. Both powders show similar flowability under minimal stress. Lactose monohydrate is characterized by easy flow, low confined flow energy, moderate cohesion, and excellent compressibility, making it suitable for applications requiring efficient flow and compressibility. Conversely, CMC displays lower cohesion but higher confined flow energy, which should be considered when selecting it as a filler. These insights provide a foundation for optimizing excipient selection based on specific processing and formulation requirements.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.