PUPSIT - Benefits Of Single-Use Technology In Pre-Use Post Sterilization Integrity Testing

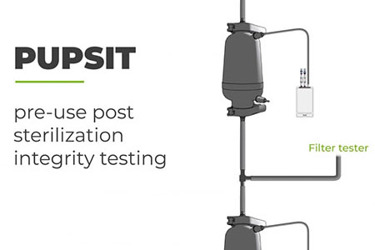

PUPSIT stands for pre-use post sterilization integrity testing. This method is performed once a sterilizing filter has been installed, and serves the purpose of filter integrity testing. In other words: PUPSIT ensures that the installed filter is functional during the sterilization and after installation process and that it complies with any regulatory requirements.

The general shift towards single-use technology in the pharmaceutical and biopharmaceutical industry can in part be attributed to the desire to eliminate certain elaborate steps like autoclaving. As systems made up of single-use components are sterilized in forehand by the supplier, autoclaving becomes obsolete and potential risks are reduced.

While pharmaceutical manufacturing plants have installed fixed pipings for fluid management made of stainless steel, medical drug product manufacturers are increasingly changing their setup to single-use technologies. One of the main advantages of single-use components is their high degree of compatibility and, as a consequence, flexibility.

Here we review the PUPSIT process and how its compatibility with single-use technology offers advantages compared to stainless-steel systems.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.