Protecting Single-Use Bags To Foster Their Progress

By Michael Eder, Business Development / Marketing Manager

Twenty years ago there was only steel.

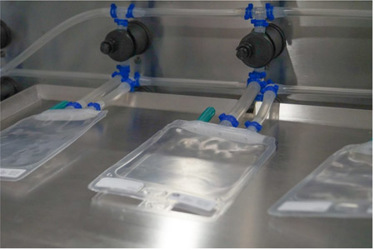

Biopharmaceutical manufacturing has been conducted by fixed stainless-steel installations for a long time. Pharmaceutical products were produced in rigid, inflexible vessels and pipings by cell culturing and/or fermentation, purification, filtering, filling and freezing. Only until single-use systems, such as single-use bags, aseptic fluid management tubings made of plastic, have proven to provide manufacturers with way more advantages for bioprocessing.

They are more flexible, scalable, faster and cost effective. And yet there is hesitation.

There is still potential product loss with unprotected single-use bags and there are still human errors dampening the euphoria of single-use systems.

Single-use bags containing highly valuable drugs consist of multi-layer plastics which are vulnerable even at ambient temperature. They become glass-like when frozen and without protection are prone to breakages when handled incorrectly. Or sometimes even when handling correctly.

By implementing a solution that protects the bag from external forces during freezing, handling storage and shipment, as well as absorbing the products’ natural expansion during freezing with a soft 3D foam, you can provides full immobilization and guarantees avoidance of product loss.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.