Packing MabSelect™ And MabSelect SuRe™ Resins Using Verified Methods

Efficient packing of MabSelect, MabSelect SuRe, and MabSelect SuRe LX resins is essential for successful chromatography in biopharmaceutical manufacturing. Proper packing prevents issues like bed cracking or compression gaps, which can cause costly disruptions and product loss. Verified methods described for AxiChrom, BPG, and Chromaflow columns ensure consistent packing, stability, and scalability.

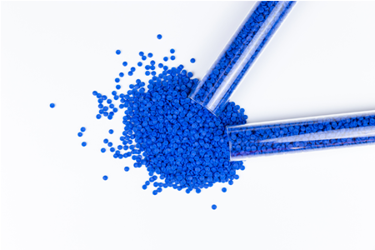

MabSelect resins, based on recombinant protein A, offer high binding capacity for IgG, and MabSelect SuRe variants provide enhanced cleaning stability with sodium hydroxide. Packing techniques include calculating resin volumes using compression and packing factors (CF and PF), adjusting for specific solutions like NaCl, and leveraging intelligent packing wizards for automation.

AxiChrom columns are recommended for scalability and uniform flow across column sizes. Intelligent packing methods automate tasks like slurry introduction, bed compression, and packed bed evaluation. BPG columns, designed for pilot scales, and Chromaflow columns, used for larger operations, also follow precise packing protocols to ensure reproducibility.

Testing packed columns for efficiency, using metrics like height equivalent to a theoretical plate (HETP) and asymmetry factor (AS), ensures performance consistency over cycles. Verified packing techniques across these systems help maintain bed stability and enable high fluid velocity operations.

These methods, supported by tools like UNICORN software, reduce operator errors, improve reproducibility, and optimize performance, ensuring robust biomanufacturing processes. For optimal results, adapting techniques to column types and resin properties is essential.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.