Minimizing Fluid Loss By Monitoring Back Pressure During Clarification

Source: Avantor

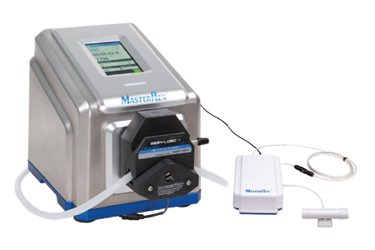

This case study highlights how incorporating back pressure monitoring in peristaltic pumping in biologics manufacturing can significantly reduce fluid loss and process risk. A biopharma CDMO experienced a costly rupture during lentiviral vector clarification, which was traced to elevated back pressure caused by filter fouling. By implementing Masterflex® MasterSense® peristaltic pumps with integrated single-use pressure sensors, the organization improved process control and mitigated the risk of future pressure-related incidents with minimal operational disruption.

access the Case Study!

Log In

Get unlimited access to:

Trend and Thought Leadership Articles

Case Studies & White Papers

Extensive Product Database

Members-Only Premium Content

Welcome Back! Please Log In to Continue.

X

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.

Subscribe to Bioprocess Online

X

Subscribe to Bioprocess Online