GMP Manufacturing Of RNA-Engineered Cell Therapies

By Matthew Pillar, Editor, Bioprocess Online

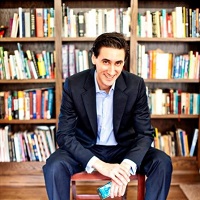

Murat Kalayoglu, M.D. reflects on his company’s GMP manufacturing approach as the company pushes ahead with first in-human studies of its RNA-engineered combination cell therapies.

Cartesian Therapeutics is on a quick pace in a hot space. Founded in 2016, the company has already grown its pipeline of RNA-engineered cell therapies to nine candidates across auto-immune, oncology, and respiratory disease indications. Four of them—Descartes-08 for myasthenia gravis, Descartes-11 and Descartes-08 for myeloma, and Descartes-30 for ARDS—have advanced to phase I/II clinical trials. With that recent and rapid activity in mind, Cartesian CEO Murat Kalayoglu joined the Business of Biotech podcast to share what he’s learned about navigating regulatory expectations for first in-human trials. Here are highlights shared by Dr. Kalayoglu on some of the topics we discussed.

FDA Guidance Is A Differentiation Enabler

“Regulators recognize that there are many different ways to end up at the same goal. The guidance they provide is appropriately broad to provide guardrails, as opposed to specific instructions. As such, guidance documents rarely indicate that something must be done according to a set plan. Companies that do well take the guidance to heart, but tailor it to meet the demands of their team and organization with respect to whatever indication they're going after and the kind of products that they're developing.”

Consistency Isn’t Easily Achieved; There Is No Precedent

We Don’t Know What We Don’t Know

“The critical parameters have to do with the inherent functionality and expansion potential of the cell. Everything else you can try to control, but there are some inherent properties that we just don't know about. In essence, we’re manufacturing tens of thousands of proteins within a given cell at any given time to determine their behavior and how they interact with one another. That’s asking a lot, relative to manufacturing a single purified protein.”

There Is No Precedent

“The guidance around small molecules and more traditional biologics has been around for many, many years and developed over time to have more structure. Cell therapy just isn't there yet. We're in the very early innings of this very long game.”

Experience, Procedure Minimizes Variability

“We do our best to minimize variability, and there's a lot that we can do. We can establish very specific SOPs, and that’s critical, because even minor things in the batch record make a huge difference. We can ensure the manufacturing organization is technically capable and staffed by a team of experienced, critical-thinking cell therapy professionals. Every single one of our operators in GMP manufacturing is an M.D., a Ph.D., or both.”

The Benefits Of In-House Control

“Everything we do is in-house. We're a fully integrated company in that GMP manufacturing is in-house. We have our own in-house quality management systems including our own clinical quality control laboratory. We do preclinical development discovery and clinical operations here. Everyone’s under the same roof, and that organization allows a lot of cross-divisional communication between folks that otherwise wouldn't necessarily be able to talk so fluidly. In fact, we've got an MD on the clinical operations side who can jump in and do GMP manufacturing. From a manufacturing perspective, I think it’s absolutely critical to have your own facility in cell therapy. We started off on this path with a CRO. It was very motivated and did a fine job, but we recognized that approach just wasn’t going to allow us to learn as much as possible for each and every engineering and production run. So, in 2018, we invested in a state-of-the-art GMP manufacturing facility and then built the entire company around it.”

It Takes A Dialog

“The folks in the cell and gene therapy space over at FDA are overwhelmed with the number of conversations that are ongoing. We’ve worked with many different divisions over the years, and we've certainly found that the cell and gene therapy division are the most engaged of any of the other divisions we've worked with. They’re really a pleasure to work with, and it speaks to the fact that you do need this type of conversation and you do need this type of back-and-forth engagement in the early stages.”

What’s Next For The RNA Armory Platform

“The platform we've coined ‘RNA Armory’ is focused on RNA engineered cell therapies and the vision is to engineer any cell to deliver any therapy or combination of therapies to any tissue. It’s a highly versatile cell therapy platform geared towards delivering not just one therapeutic, but multiple therapeutics directly to the site of disease. We're using the cell as not just the production factory, but also the vehicle for therapeutic delivery, specifically to diseases that don’t often respond to single-drug treatments. The number of iterations and combinations you come up with is really limited only by our imaginations.”

Tune into the conversation in its entirety on episode 48 of the Business of Biotech podcast.