bio-formulation-995x60

bio-formulation-995x60

FEATURED ARTICLES

-

The Hidden Challenges Of ADC Manufacturing - And How To Overcome Them

ADC manufacturing requires specialized expertise, single‑use systems, precise filtration, aseptic filling, and integrated lyophilization to ensure stability, safety, and consistent clinical‑grade production.

WHITE PAPERS & CASE STUDIES

-

Levers To Optimize The IVT Reaction For Increased mRNA Yield

Mastering IVT yield requires balancing magnesium and nucleotide ratios. Learn how specific buffers and pyrophosphatase optimize mRNA synthesis for scalable, high-quality therapeutic production.

-

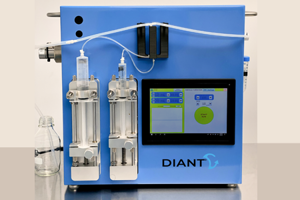

Accelerate LNP Manufacturing With Automated Process Development

Manual LNP formulation introduces process variability that threatens particle quality and yield. As programs scale toward clinical production, maintaining strict control over CQAs becomes essential.

-

Oligonucleotide Purification And Synthesis

Examine how a 21‑mer oligo was synthesized and purified through systematic resin screening, method optimization, and successful scale‑up to build reliable, high‑purity chromatography workflows.

-

Selecting A CDMO For Custom Activated PEGs

Custom-activated PEGs require thoughtful planning and precise analytical control. Discover key considerations for selecting a partner capable of supporting scalable, compliant PEGylation.

-

How GLP-1s Are Redefining Injectable Care For Chronic Conditions

GLP‑1 therapies are changing injectable care and driving rapid progress in delivery and manufacturing. See how patient needs, emerging tech, and regulations are reshaping chronic treatment.

-

Using DSC And MDSC To Study Material Interactions Of APIs And Excipients

Thermal analysis reveals how particle size and morphology influence material interactions and stability. Learn how DSC and MDSC techniques uncover compatibility issues and guide better excipient selection.

ABOUT

Formulation

Formulation in bioresearch is directly associated with pharmaceutical research and development. It is the practice of combining different chemical substances that include the active medical drug. This combination of drug and chemicals is tweaked until they have a final medicinal formulation that can be tested and receive final approval for large-scale market use.

The object of pre-formulation and formulation is to develop a stable preparation of a specific drug that is acceptable for human consumption. All drugs, by necessity, contain other chemicals. In order to put a drug into a capsule or tablet form it requires a variety of substances other than the drug itself. Formulation is needed to ensure that the drug will work when combined with these other substances.

It may surprise you to know that most formulations are not complete until after Phase III clinical trials are in progress or completed. All the early trials test drug stability, and drug load, which is the ratio of active drug to the total content of the actual dose.

Formulation studies address a variety of issues includinggrain size, pH (acidic or alkaline), solubility, and polymorphism (the ability of a drug to exist in more than one form like liquid and capsule). Other items formulation addresses is taste, appearance, tablet hardness and tablet or capsule disintegration.

Another aspect of formulation is testing how humidity, temperature, oxidation, ultraviolet light or visible light affects the formulation. The formula must be stable and not degrade under all of the different environmental factors.

Formulation involves a lot of experimenting with different blends of materials and drugs, but is absolutely crucial for the development of effective, safe, stable, oral drugs, and topical ointments.