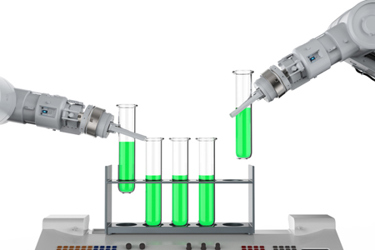

Why Aren't QC Labs Automated? Blame Sample Container Variability

By David Wolton

What pushes up the cost of automating QC equipment using robotics?

It appears there are two key drivers. The first is the lack of plug-and-play software (covered in my first article on the subject). The second is the variability of what a QC robot will need to physically interact with.

Things are starting to change, partly due to the needs of cell and gene therapy manufacturers. Robot-friendly cryovials are now available and starting to be used for samples.

Sadly, there is no industry body currently interested in the topic of sample container standardization, which means we are a long way from standardizing containers being used in QC.

With this in mind, I asked a group of industry experts from the Laboratory Automation Plug and Play (LAPP) group about their experiences and thoughts on the topic.

In your company, roughly how many different types of sample container types are booked into sample reception?

|

A few dozen. I do not know the exact figure, but it is not a small one. They vary in shapes, volumes, openings, material, haptics, etc. Miguel Alvarino — Lonza |

|

|

Company 1 — around 10 to 20 (including those for raw material samples). Company 2 — around five. Company 3 – around 50. Youjie Zhang – Ramskov Consulting Group |

|

Estimate how many types of sample containers are used in your QC lab, excluding microbiology samples.

|

A few dozen as well. Less than before the aliquotation but still a significant number. After aliquotation, you still have to use small-size bottles for some testing procedures and different types of vials for the rest of the tests. Miguel Alvarino — Lonza |

|

|

Company 1 uses more than 20. Youjie Zhang – Ramskov Consulting Group |

|

Have you come across a situation where the vendor will not move away from their preferred sample container?

|

Very few vendors enter the customization business. Very few can undertake such an effort internally. Therefore, most of the customization is done by third parties: integrators, subcontractors of the vendor, etc. Miguel Alvarino — Lonza |

|

|

We have seen this; however, we solved the problem using a 3D-printed adapter for the liquid handler. Adam Wolf — Takeda |

|

What percentage of the types of sample containers could be replaced by a pre-barcoded cryovial, excluding microbiology samples?

|

Being conservative, I would expect a figure above 50% of the total containers after aliquoting. I am not sure we will be able to reduce all vials to just one. But at least the shape and opening could be the same. Materials might vary depending on the properties of the product, but at least we would have standardized the shape and, therefore, the storage would be easier. Miguel Alvarino — Lonza |

|

|

It’s difficult to estimate for various reasons. However, it is unlikely the barcoding would be compatible with Company 1’s global LIMS setup. Youjie Zhang – Ramskov Consulting Group |

|

What barriers do you think there are to moving toward an industry standard for pre-barcoded cryovials?

|

The requalification effort and cost associated with changing the format. Adam Wolf — Takeda |

|

|

Vendors — especially the ones that are not selected in terms of technology — are very resistant to accept any standardization. Tom Kissling — Roche |

|

|

Vendors do want to sell their formats to avoid competition. Once you start using a particular one, you are not going to change to a different vial from a different provider. Therefore, vendors alone are not going to find a compromise to standardize anything unless they find a competitive advantage. Also, the pharmaceutical industry has not had an open discussion with vendors about it. This lack of standardization has a huge impact in the automation efforts undertaken at different labs (R&D, AD, QC, etc.). Miguel Alvarino — Lonza |

|

|

At Company 1:

Importantly, overcoming barriers comes down to the cost vs. benefit calculation, and manufacturers must ask themselves: is there a strong enough business case to bring in standardization? Youjie Zhang – Ramskov Consulting Group |

|

Conclusion

As you can see from the answers, there is still a lot of room for improvement; and it's not just about haptics — existing barcoding and automation solutions can also hold back rationalization of containers. However, there is promising light on the horizon. A leading biopharma company in Switzerland recently implemented mobile robots to transport samples directly from production areas to automated fridges, eliminating the need for sample reception. As part of this initiative, they adopted automation-friendly cryovials, proving it can be done.

Will standardization lead to even greater automation within the laboratory? Only time will tell.

About The Author

About The Author

David Wolton is an independent biologics manufacturing consultant based in Zurich. He has decades of experience managing teams, designing equipment, and designing facilities. He specializes in single-use equipment, automation, and mobile robotics.