Three Key Actions To Minimize Dead Volumes

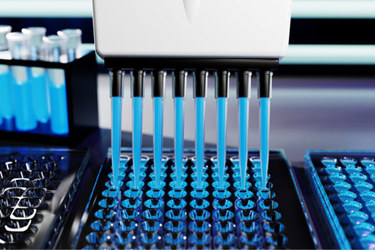

Reducing liquid dead volume is a critical factor in optimizing the performance of automated liquid handling systems—especially when working with costly reagents or limited sample volumes. Lower dead volume translates directly into less waste, which enables labs to stretch valuable materials further and run more assays per unit volume. This not only improves cost-efficiency but also enhances throughput and data generation per cycle.

Advanced liquid level detection technologies, such as Adaptive Signal Technology™ (AST), are helping labs achieve these goals without compromising precision or accuracy. By enabling more accurate detection of liquid levels, AST minimizes the residual volume left behind in pipetting processes. The result is a more efficient use of resources, reduced manual intervention, and improved consistency across workflows.

For labs focused on high-throughput screening, assay development, or any application where reagent conservation is key, understanding how innovations in liquid handling can reduce dead volume is essential. Explore how these technologies are reshaping lab efficiency and unlocking new possibilities for data-driven decision-making.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.