The Crucial Role Of Downstream Processing In Optimizing RNA-LNP Drug Development

Companies embarking on LNP development often opt to manage this intricate process in-house, leveraging their expertise and resources to engineer nanoparticles with precision. However, cultivating expertise in LNP development is a complex and time-intensive endeavor. From the initial lipid synthesis to the encapsulation of RNA molecules within stable nanoparticles and the establishment of critical quality attributes (CQAs), the process demands a high level of specialized knowledge and experience. Designing a specialized laboratory can take years, and validating manufacturing processes and developing in-house capabilities necessitates significant time, effort, and investment. This includes recruiting and training highly skilled scientists, engineers, and technicians, and continuously enhancing their skills to stay competitive in this rapidly evolving field. Alternatively, outsourcing offers a different path, potentially accelerating access to specialized expertise, facilities, and workflows. Leveraging access to this expertise can also help meet project goals and timelines.

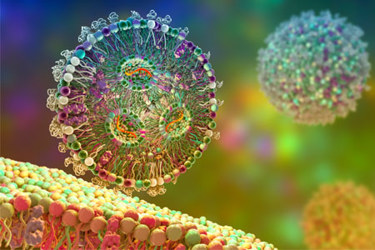

Thus, deciding to outsource RNA-LNP development and production is a strategic move that can place biopharmaceutical companies at the cutting edge of innovation and competitiveness, offering faster progress with the benefits of customization and efficiency. Here, the key aspects of LNP development are explored, highlighting essential downstream processes including Tangential Flow Filtration (TFF) and normal flow filtration. These processes are crucial for ensuring the purity, potency, safety, and stability of RNA-LNP formulations, underscoring their critical role in the development of genomic medicines.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.