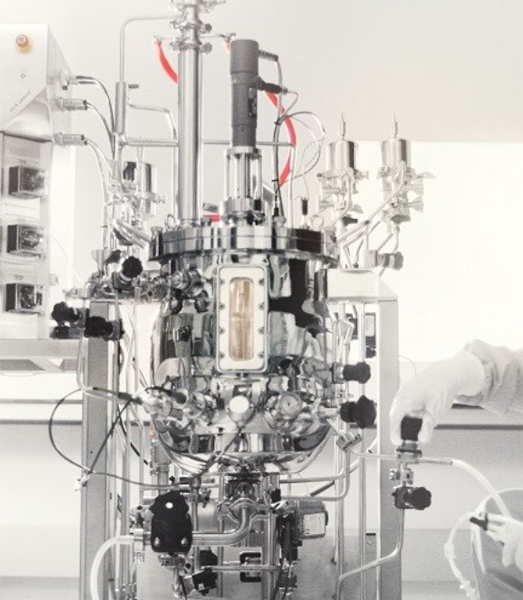

Sterilize-In-Place Bioreactor For Small-Scale Production

Applikon BioPilot

The multi-use Applikon BioPilot is the first step towards bioprocess production. The BioPilot is linearly scaled up from lab-scale bioreactors, which simplifies the transfer to production resulting in a quicker time-to-market. The consistent concept of modularity, using standard modules to build the bioreactor, simplifies customization to meet any specific requirements for microbial and cell cultures.

Accurate scale-up model for production

- Compact design reduces floor space needed

- cGMP compliant design simplifies validation

- Modular design allows easy configuration to match process demands

- Worry-free operation by minimizing human errors

Essential in developing vaccines and medicines

Bioreactors play a key role in developing and producing life-saving vaccines and medicines. This complex process requires highly optimized, state of the art systems. With the Applikon BioPilot standardized bioreactor designs, we provide ease and flexibility of customizing the vessel to handle any type of application needs with standard components.

Do you know...

- We have supplied stainless steel bioreactors for over 30 years

- GMP stainless steel bioreactors are one of our specialties

- we have supplied hundreds of production bioreactors worldwide

- you can combine add-on packages to upgrade your bioreactor

Scaling up from small volumes to full production volumes is key in every bioprocess and can be a challenge at the same time. To simplify this process, we provide Applikon BioBench and BioPilot stainless steel bioreactors systems, developed according to our well-known Applikon standards and built with the same modular approach that we apply to our lab-scale bioreactors. This enables you to configure a bioreactor with basic functionality into a fully featured bioreactor, simply by expanding your system with various add-on packs. Upgrade your bioreactor system to your specific application needs.

#GrowWithUs

The Applikon BioPilot is ideal for the following applications:

- Scale-up studies

- Medium optimization

- Process optimization

- Small scale production

- Seed train

- Microbial and cell culture

- Batch, Fed-Batch, Perfusion and Continuous cultivation

Applikon BioPilot Features

Easy to validate- The BioPilot range is built to the latest standards on hygienic processing, meeting cGMP and GAMP requirements, and can be supplied with an extensive documentation package to support efficient validation.

Easy to operate- Stainless steel bioreactors minimizes the risk of contamination as there are no consumables to be replaced for every single run. Furthermore, these Sterilizable-in-Place bioreactors are supplied with magnetic coupled agitator connections. Whereas the agitator shaft continues from the outside to the inside of the bioreactor with traditional connections (lipsealed or double mechanical seal), here the connection is established via magnets. Since there is no connection with the outside world, there is no risk of contamination. The open frame construction gives easy access for maintenance and operation.

Easy to clean- The Applikon stainless steel bioreactor range is completely fabricated using pharma-grade 316L stainless steel and supplied with a surface finish of Ra < 0.4 micron. This smooth surface ensures that biofilms and debris will not stick to the internals of the bioreactors. This greatly simplifies the cleaning procedure and creates ease of mind knowing that the bioreactors will always be reproducible clean.