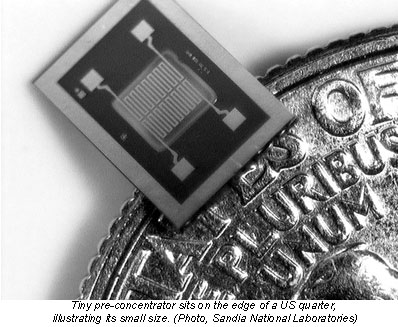

Sandia develops sample pre-concentrator for miniaturized chemical analysis units

Although intended primarily for the hand-held unit, the pre-concentrator can potentially be integrated with other micro chemical detectors, Sandia says, including a mass spectrometer or an ion mobility spectrometer.

The hand-held device in which the pre-concentrator is a component will eliminate the need to send samples to a large laboratory, Sandia explains. Advantages of the unit, notes Ron Manginell, a researcher at the lab, include its small size, low power consumption, portability and relatively low production cost.

A traditional pre-concentrator consists of a cigarette-size stainless steel tube packed with an adsorbent material. A pump forces the sample gas through the tube where it is adsorbed into the material. The steel tube then goes into a benchtop thermal desorber and is heated to 200º C. The gas escapes from the tube for analysis by a detector such as a benchtop gas chromatograph. Manginell says this traditional system is bulky, slow, and must be done in a laboratory setting -- not at all practical for field testing, in which the hand-held device would be highly useful.

Project lead Greg Frye-Mason says the microfabricated planar pre-concentrator is a "revolution" in front-end sampling devices. According to a Sandia description, the device is made using standard integrated circuit microfabrication technology that allows 200 units to be built on a single 4-in. (5 cm) silicon wafer. The unit has a silicon base topped by a one-half micron layer of silicon nitride. The silicon nitride membrane, formed by etching the silicon away, holds a patterned platinum heater, called a micro-hotplate. A thin layer of an adsorbent material goes on the front surface of the heater. Gold pads surround the device and help to connect the platinum heater electrically to the macroscopic world.

The micro pre-concentrator operates much like its larger relative. First, a small pump pulls air containing a chemical over the adsorbent material. Current flows through the platinum, heating up the micro-hotplate to 200º C. The high temperature causes the chemical to be released from the adsorbent material so it can be analyzed by a micro detector system.

"All this happens in the blink of an eye," Frye-Mason says in a Sandia press release. "It takes six milliseconds and 100 militates of power to reach 200 degrees. That's 1,000 times faster than using the conventional method."

Edited by Gordon Graff

Managing Editor, Laboratory Network.com