Reducing Risk For The mRNA Manufacturing Surge

By Life Science Connect Editorial Staff

Since the COVID-19 vaccines ushered in a new wave of mRNA possibilities, drug developers have sought innovative ways to leverage this targeted genre of vaccines and therapeutics. The rapid development and manufacturing response to the pandemic proved that high-quality mRNA vaccines can be produced with speed and quality. However, the relative newness of mRNA therapeutics has resulted in a major learning curve for drug developers and the CDMOs they partner with. In the recent Bioprocess Online Live event Risk Reduction In mRNA Therapeutic Development hosted by Matt Pillar, mRNA experts Patrick Baumhof, vice president of formulation & delivery at CureVac GmbH, and Christian Dohmen, senior director of formulation & aerosol research at Ethris GmbH, discussed the mRNA boom, the difficulties inherent to mRNA manufacturing, and the strategies they have identified to mitigate risk and produce safe, high-quality products.

Why The mRNA Surge?

mRNA offers several advantages for treating disease, including the ability to guide protein directly to its intended target. Baumhof’s company, CureVac, is the first to leverage mRNA for medical treatments; currently, they have a variety of prophylactic vaccines in their drug development pipeline, including multiple to treat influenza and COVID-19. Per Baumhof, “mRNA can encode every protein and build transmembrane proteins. It has a unique pharmacokinetic expression that can drive biological functions and use them for vaccine and therapeutic purposes. It can manipulate disease states on levels that are not typically reached by other drugs.” To effectively harness mRNA’s possibilities to treat patients, stakeholders must identify strategic approaches to avoid the challenges inherent to mRNA production.

What Are The Challenges Associated With mRNA Manufacturing?

To ensure efficient production of high-quality mRNA vaccines and/or therapeutics, the following concerns must be adequately addressed:

- Production scale-up challenges, including the limitations of chromatography, which must be addressed in order to generate a large, consistent supply of mRNA products

- Safety profiles that improve in tandem with the scale-up process

- Immunogenicity that is optimized for specific disease states

- A raw material supply that provides high quality and consistency

Using chromatography for large-scale mRNA production is often inefficient. Baumhof elaborates: “Chromatography is a complex process. At some point, scaling the dimensions of your column becomes a problem. It has disadvantages for process time and yield, especially if you aim to produce millions or billions of doses. That said, current vaccines on the market are delivering in the multi-billion dose range. Since chromatography is prohibitive from a process development standpoint, try to find alternatives to make your production faster and more versatile.”

Dohmen highlighted how his company, Ethris, which is designing mRNA therapeutics to treat rare pulmonary diseases, has avoided using chromatography in these scenarios: “As a therapeutic mRNA company, we need to design scalable processes and produce high-quality mRNA with said processes. We are currently focusing our efforts on processes that are high-performance liquid chromatography (HPLC) free; we tackle this mainly via tangential flow filtrations. You have to play around with conditions to meet the quality desired for the development of therapeutic drugs. If you run the right process, it will be both high-quality and scalable.”

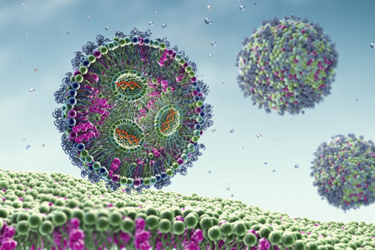

The stability of your LNPs throughout production is also critical. Per Dohmen, “LNPs in mRNA production are composed of a lipid that interacts directly with the mRNA, as well as helper and PEG lipids. Many LNP formulations tend to aggregate if you treat them wrong during manufacturing processes. When it comes to immunogenicity, the agglomeration of LNPs into larger fragments can have immunological effects that are difficult to control. If this is avoided and suspension is stabilized, this significantly improves your product’s safety profile. For LNPs, it’s important to choose the right components and provide proper shielding to avoid undesired side effects.”

For an mRNA therapeutic or vaccine to have a strong overall safety profile, a purification step to remove harmful impurities is critical. “In the future, there will be a lot of different production processes for different types of mRNA in place. In the end, however, there will need to be a purification step to get rid of byproducts that may influence your reactogenic profile,” Baumhof notes.

Ultimately, the solution to a given manufacturing challenge might be dependent on the targets for the disease being treated. Furthermore, the type of indication and application can determine which mRNA format is best suited for treatment. Possibilities include linear mRNA, circular mRNA, self-amplifying mRNA, oligo RNA, and siRNA; each of which offers its own distinct advantages and disadvantages.

What Are The Primary Risks?

Both supply chain delays and cold chain requirements are top of mind for mRNA developers and manufacturers. To establish a reliable supply chain, both Dohmen and Baumhof recommend forming partnerships with reliable suppliers who are highly communicative and skilled at navigating long lead times for critical supplies. Developers, manufacturers, and suppliers should work collaboratively to develop realistic production timelines and secure a reliable supply of critical raw materials.

Currently, mRNA vaccines require cold chains that maintain temperatures as extreme as minus 80 degrees C to ensure safety and stability upon delivery to patient. To help make both mRNA vaccines and therapeutics more accessible to patients around the world, both Dohmen and Baumhof believe developers will need to identify strategies for maintaining quality and stability at more manageable temperatures.

At Ethris, they have already identified some potential solutions to these extreme requirements, perhaps most notably by leveraging lyophilization to create long-term storage stability. Dohmen elaborates: “In the therapeutic fields, it's even more important to have [fridge temperature] conditions so that patients might receive their dose at home. To go a step further, room temperature conditions would simplify everything. While working on a therapeutic to treat respiratory disease, we addressed this quite early. We have an LNP formulation that is stable at minus 20 degrees C, which simplifies the cold chain significantly. We are also working on research for a lyophilization process that supports stability for up to half a year at room temperature without any loss of LNP quality.”

For those looking to create the next wave of mRNA treatments, these safety risks will need to remain top of mind. Despite these challenges, Dohmen is optimistic: “There is clear evidence and literature that shows that modified mRNA has clear advantages over non-modified mRNA. For modified mRNAs, the safety profile for the marketed vaccines has been demonstrated and proven. Doses have been applied to numerous people and the safety profile is very good.”

What’s Next?

As the pharma industry strives to leverage mRNA to treat diseases on a global scale, drug sponsors must be innovative and forward-thinking in their approaches to development and manufacturing. Due to the relative novelty of the form, many mRNA developers are coming up with new approaches and technology to achieve stability, establish critical quality attributes, and guarantee a safe, high-quality product for patients.

To view the Bioprocess Online Live event, “Risk Reduction in mRNA Therapeutic Development” in its entirety, click here.

References

- Harnessing the potential of mRNA. Pfizer. https://www.pfizer.com/science/innovation/mrna-technology