Reducing ADC Timelines With Integrated Development And Manufacturing Services

By Thomas Rohrer, Senior Director of Technical Support, Bioconjugates, Samsung Biologics

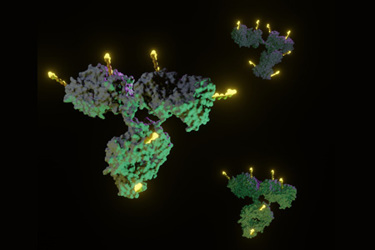

Antibody-Drug Conjugates (ADCs) are a revolutionary class of cancer drugs designed to deliver potent chemotherapy directly to tumors. Unlike traditional treatments, ADCs minimize harm to healthy cells, offering a promising new approach in the fight against cancer. ADCs have proven to be highly effective in cancer treatment, but their manufacturing poses challenges due to the specialized capabilities required. Samsung Biologics, a leading contract development and manufacturing organization (CDMO), is making significant strides in the field of antibody-drug conjugates (ADCs). Samsung Biologics aims to simplify ADC projects by offering integrated capabilities for their development and manufacturing.

This article explores the growing impact of ADCs and the challenges associated with their complex manufacturing process. The intricate nature of ADCs, with their unique combination of antibodies, linkers, and payloads, necessitates a multifaceted production approach. The article highlights the benefits of integrated manufacturing, where all aspects of ADC development and production are streamlined under one roof. This integrated approach can significantly reduce development timelines and ensure consistent quality control.

The future of ADCs is brimming with potential. As scientific understanding continues to evolve, researchers are developing even more effective targeting agents, payloads, and linkers. This continuous innovation will allow ADCs to target a wider range of cancers and improve patient outcomes.

Learn how a CDMO partner with expertise and integrated manufacturing capabilities can help bring these innovative treatments to patients safely and efficiently.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.