Perfect Potent API Processing: Handling Hazardous Drug Actives Effectively

A Q&A with David O’Connell, PCI Pharma Services

The journey from discovery laboratory to pharmacy shelf is long and arduous, particularly for highly potent APIs, which must be handled in compliance with complex regulatory requirements at each stage of the journey.

Pharmaceutical companies looking for a Contract Development and Manufacturing Organization (CDMO) to help them navigate should look for one with a combination of true expertise, capabilities and a robust assessment process giving all molecules a “potent passport” according to David O’Connell, Director of Pharmaceutical Development at PCI Pharma Services.

INTRODUCTION

High potency active pharmaceutical ingredient (HPAPI) processing is an attractive market for CDMOs.

Regulatory demand for effective, lower-dose treatments combined with growing incidents of cancer, diabetes, and cardiovascular diseases has seen many pharmaceutical companies focus their R&D investments in HPAPI-based products. This focus, paired with the ever-present need to reduce costs, has increased demand for HPAPI processing services.

Another factor driving CDMO interest in HPAPIs is differentiation. Competition in the contract manufacturing industry is fierce, particularly in traditional API processing.

Many U.S. and European CDMOs have struggled to compete with rivals based in locales where wages, energy, and raw material costs are lower. In response, some contractors have focused their efforts on offering specialized services that competitors elsewhere cannot, including HPAPI processing.

As a result, the number of CDMOs offering HPAPI processing capacity has increased dramatically. However, while many organizations claim to be able to work with such materials, very few have the experience, expertise or equipment needed to complete such projects efficiently, and even fewer have the ability to support initial development through to long-term commercial supply.

Choosing a CDMO to take on an HPAPI project is a complex business requiring detailed assessment. There are significant safety and regulatory challenges involved in HPAPI production and specific considerations for a pharmaceutical company selecting a partner.

API POTENCY

An API is defined as a substance that has pharmacological activity in a finished drug product1. An API is deemed to be highly potent if it meets one or more of several criteria, primarily if it has biological activity at a dose of 150 μg/kg of body weight, is able to bind to specific receptors, is oncogenic, or has the potential to cause developmental defects2.

There is no standard definition of a highly potent API. Often an API is also classified as highly potent if it has an Occupational Exposure Limit (OEL) of below 10 μg/m3 of air as an eight-hour time-weighted average. This is the critical definition from a manufacturing and processing standpoint, as such substances require specialized handling and containment under current regulations.

The challenge for manufacturers is that HPAPI handling and engineering containment regulations differ depending on both the agency involved and the market.

HPAPI REGULATIONS

In general, regulations covering the sterile processing of highly potent products impose stricter handling and employee safety requirements than those covering standard drug product processing.

For example, guidelines such as Occupational Health and Safety Management System (OHSMS) 18001 and ISO 14001 set out clear worker safety and environmental health standards for HPAPI processing. A number of other specific regulations cover HPAPI manufacturing and processing.

U.S. and European current Good Manufacturing Practice (cGMP) guidelines also cover HPAPIs, detailing how manufacturers should try to avoid cross-contamination, clean equipment, and handle various substances3,4.

HPAPI handling requirements are also set out in FDA guidance on aseptic processing, in sections covering the containment of ingredients during manufacture5, and in the International Council for Harmonization (ICH) document on quality systems, ICH Q106.

A number of International Organization for Standardization (ISO) standards also pertain to HPAPIs. These are: ISO 13408 on aseptic processing; ISO 14664-1 on cleanrooms and controlled environments; and ISO 11134, 11137, and 14937 on sterilization.

In summary, while regulations and standards covering HPAPIs have similar themes relating to containment, cleaning, and handling, the large number of requirements and the differences among them can pose significant challenges for a manufacturer.

TECHNOLOGY INVESTMENT

Pharmaceutical companies are used to working in a strictly regulated environment7. In addition, regulations covering HPAPI containment and processing differ depending on the destination market.

The containment technologies and cleanroom capacity required to comply with the regulations are expensive, particularly for manufacturers supplying multiple markets. In addition, while safety technology testing guidelines are available8, there is little regulatory guidance covering HPAPI facility design.

As a result, many pharmaceutical developers with products containing HPAPIs choose to outsource manufacturing to a CDMO with established capabilities and experience in handling such materials in compliance with all the applicable regulations9.

CHOOSING THE RIGHT CDMO FOR A HPAPI PROJECT

Outsourcing HPAPI processing to a CDMO allows pharmaceutical companies to avoid investing in dedicated facilities and the specialist containment and handling technologies required to work with such materials10.

The challenge is finding a CDMO that has both the technical capabilities and experience to take on an HPAPI processing project11.

The following is a best practices guide that pharmaceutical companies should use to assess CDMOs prior to outsourcing any HPAPI project.

OEL BANDING AND TESTING CAPABILITIES

The first stage of the CDMO selection process should focus on the contractors’ HPAPI handling capabilities. CDMOs that work with HPAPIs usually tailor their handling and containment requirements based on the potency of the material in question.

Potency is assessed according to one of a number of banding systems12. While the systems are similar; there is considerable variation between contractors. For example some companies use a four band system, while others prefer a six band system. It is therefore advisable to choose a contractor that adheres to a banding system that is most appropriate for the specific HPAPI.

For early-phase development compounds whose potency has been estimated rather than measured13, selecting an appropriate CDMO is even more important.

Potency estimates can be used to ensure HPAPIs are managed safely during the early phases of a project due to the lack of available toxicology information. However, when the substance moves from preclinical to clinical development, it is usually necessary to accurately determine potency.

There are distinct time and cost advantages to working with a CDMO that is capable of making such determinations in-house, and it is important to fully assess such capabilities before selecting a partner.

AVOIDING CROSS-CONTAMINATION AND EQUIPMENT

A CDMO’s approach to preventing cross-contamination should also be assessed before any project is outsourced. Preventing contamination can be achieved using dedicated or disposable technologies.

Some CDMOs use the same equipment for multiple HPAPI projects. It is highly advisable to conduct a detailed review of cleaning protocols ahead of time. CDMOs with data showing their cleaning protocols consistently reduce product residue, cleaning agent residue, and microbial levels to the appropriate levels should be favored.

ENVIRONMENT HEALTH ASSESSMENT

Another means of assessing a CDMO is to conduct an Environment, Health, and Safety (EHS) audit, which will establish if the organization has capacity to contain the HPAPI and protect its employees and the wider environment14.

EHS audits take time and can delay HPAPI projects. To address this, some CDMOs use independent experts to assess their operations on a continual basis which is a useful indication of compliance with containment and handling regulations. Other CDMOs use in-house assessments that are no less rigorous than those conducted by consultants. Either way, determining a CDMO’s EHS mind-set prior to any project is critical.

CONTAINMENT TECHNOLOGY

Assessing a CDMO’s production, processing, and containment capacity should be a key part of the selection process. However, for HPAPI projects, it is also advisable to find out if the CDMO candidate has relationships with technology suppliers.

As previously stated, there are few clear HPAPI facility design guidelines. As a result, most manufacturing operations for such substances are custom-developed for each project. In such circumstances, a CDMO that regularly interacts with developers of containment technology is best placed to identify areas of improvement and to access the latest technology. For example, bespoke containment solutions should be tested in accordance with guidelines set up by the ISPE.

CONCLUSION

Assessing a CDMO’s capabilities, track record, compliance history, and ability to provide long-term support is key to the success of any outsourcing decision. However, the additional complexity and higher regulatory hurdles involved in processing HPAPIs make choosing the right CDMO for such products even more important.

Clearly, cost of goods and services and a CDMO’s financial stability are important, but for an HPAPI project, cost should not be the determining criteria. Instead, assessment should be based on the CDMO’s ability to handle and process HPAPIs in a way that keeps employees safe and is in compliance with regulatory requirements.

Similarly, access to the latest containment technology is also a good indication of a CMO’s HPAPI processing capabilities. Furthermore, a CMO should actively track the evolution of applicable regulations in all major markets.

PLANNING, POTENT PASSPORTS, AND TEAMWORK — KEYS TO HPAPI PROJECT SUCCES

All CDMOs understand that handling potent APIs requires careful planning and implementation at each stage of the process, from receipt of materials through distribution.

How well these activities are performed is determined by a contractor’s experience, infrastructure, and relationships with suppliers, according to David O’Connell, Director of Pharmaceutical Development at PCI Pharma Services.

How does PCI approach a HPAPI project? O’Connell: The first stage of every HPAPI project PCI undertakes is a detailed assessment of the material. We try to find out as much about the API as possible, everything from basic CMC (chemistry, manufacturing, and control) parameters to details of processes used by other companies in the supply chain. The aim is to determine whether a project can be handled using existing resources or whether we need to add new capabilities.

How complex is the process? O’Connell: Gathering this information is very complex and requires all the expertise PCI has gained through it many years working with HPAPIs. One of the major challenges is that not all of this information is available for every project.

For example, smaller customers often operate with a “virtual CMC” approach that relies on development conducted by third parties. In such circumstances, gathering the necessary data can take time and delay projects unless you know precisely what information you need. In contrast, larger customers usually are able to supply detailed material specifications and a complete toxicology package.

So, how does PCI carry this out? O’Connell: In circumstances where the information isn’t available — and this applies to both standard API and potent API projects, we use a precautionary approach and treat all materials as potent. This means we use handling and containment protocols specifically developed for hazardous materials.

Aside from the obvious safety considerations, the precautionary approach is beneficial for our customers who can use the detailed records to illustrate their materials have been handled in compliance with regulatory requirements at every stage of the process.

Once the information has been gathered, what is the next stage of the process? O’Connell: The next stage is to assess the project in terms of PCI’s in-house capabilities. The containment required when handling HPAPIs can only be achieved using the appropriate technologies.

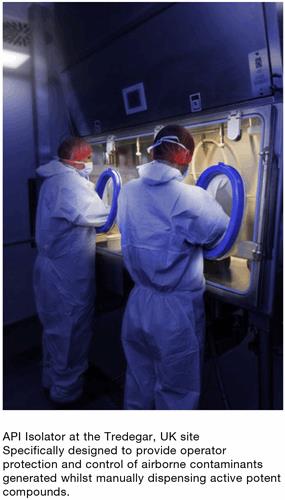

Once we have the basic CMC and toxicology information, we look at capabilities at our facility in Tredegar near Cardiff, Wales to determine if the systems we have in place are sufficient to ensure we can handle the specific material in a safe, compliant, and contained manner. If necessary, we then work with our in-house engineering team and to fine-tune our systems to the project.

We have a considerable track record in this area that dates back to capabilities developed at Penn Pharma [a specialised CDMO acquired by PCI in 2014 with over 30 years’ experience in the development and manufacture of highly potent molecules]. An example of this is that we work as an engineering consultant for companies that work with HPAPIs.

What level of technological know-how is required to ensure an HPAPI is handled properly? O’Connell: Well, as I said, PCI has considerable in-house expertise in engineering and development of the handling and processing steps required for the safe handling of HPAPIs.

Our in-house expertise is vital in determining the OEL for a particular material. The internal team assesses the molecule based on the CMC, toxicology, and other relevant data and feeds this information back to the customer as a potent passport.

A potent passport strongly defines the molecule, its mode of action, and the appropriate handling requirements. This documentation then follows the molecule throughout its life-cycle and its journey through our Contained Manufacturing Facility.

Another advantage we have is our strong links with technology and equipment developers. We work in collaboration with technology developers on the systems required for specific projects. This ranges from the provision of feedback on how a particular piece of technology performs in a real world setting to testing innovative systems. We find our relationships allow us a great deal of flexibility, which is valued by customers.

Our customers also value our ability to work on different scales of HPAPI projects. At our Tredegar facility we have two equipment trains; a small-scale and a larger-scale which customers appreciate. The ability to test a process at a smaller scale allowing our customers to mitigate risk. This “design for manufacture” approach and geometric scale-up of equipment ensures a smooth transition from development, through clinical to commercial scale delivering true speed to market for our clients.

Modern CDMOs often conduct multiple HPAPI projects in parallel. How challenging is it to ensure the requirements of each of these projects are understood and correctly implemented by all staff members? O’Connell: Understanding the specific handling requirements is vital to the successful completion of any HPAPI project. To do this requires a team effort, another advantage of PCI’s potent passport approach. PCI’s documentation required to determine the assignment of a potent passport clearly sets out how each material should be handled by all personnel at every stage of the process keeping our staff safe and allowing our customers to ensure their materials have been handled in compliance with the appropriate regulations.

The potent passport approach also allows us to use a modular approach to staff training, whereby members of our team are trained to handle materials based on our determination of their potency. This minimizes costs, giving us an advantage over our competitors, and allows us to update specific parts of our staff training programs as needed.

Expertise in HPAPI handling is clearly an important part of PCI’s approach …O’Connell: Absolutely. Our team is our strength, and we actively try to ensure that we have the best people combined with investment in leading edge technology and latest scientific developments.

How is this achieved? O’Connell: We have very strong links with academic institutions, both locally, for example Cardiff University, and internationally. We recently hired two analytical chemists who studied at Cardiff, and our analytical group works with researchers at Cardiff and other institutions.

Pharmaceutical industry customers really value scientific expertise, particularly clients from the U.S. and Japan, who often ask for information relating to percentage of degree educated employees through to how many Ph.D.s we employ before projects begin.

In 2014 we were awarded ISPE Facility of the Year for a, purpose built Contained Manufacturing Facility. This facility is truly market leading, providing customers with a state of the art facility for the development and manufacturing of highly potent molecules.

The facility has the ability to process multiple compounds from development to commercial scale and the containment technology allows us to safely process molecules with an OEL down to 0.01µg/m3. Equipment includes a high shear mix granulator, fluid bed drier, contained Xcelodose® technology delivering drug in capsule/vial options for early stage clinical trial and first in man studies, contained roller compaction for products sensitive to heat and moisture, tablet and capsule technology and associated bottle and blister packaging. Contained engineering solutions eliminate the need for traditional Personal Protective Equipment (PPE) and automated cleaning procedures along with a purpose built high performance and bespoke effluent treatment facility, ensures that we are able to meet global regulatory standards including the FDA, the MHRA, ANVISA and the Turkish Ministry of Health. The design for manufacture approach through geometric scale up delivers true speed to market for our customers.

References

1. http://www.who.int/medicines/areas/quality_safety/quality_assurance/DefinitionAPI-QAS11-426Rev1-08082011.pdf

2. http://cat.inist.fr/?aModele=afficheN&cpsidt=18761959

3.http://www.ecfr.gov/cgi-bin/text-idx?SID=3ee286332416f26a91d9e6d786a604ab&mc=true&tpl=/ecfrbrowse/Title21/21tab_02.tpl

4. http://ec.europa.eu/health/files/eudralex/vol-4/chapter_5.pdf

5. http://www.fda.gov/downloads/Drugs/.../Guidances/ucm070342.pdf

6. http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q10/Step4/Q10_Guideline.pdf

7. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=30061

8. http://www.sciencedirect.com/science/article/pii/S0098135400003884

9. https://webstore.iec.ch/publication/24241

10. http://lifesciences.thomsonreuters.com/m/pdf/Bowman_SCM_Jul13.pdf

11. http://www.americanpharmaceuticalreview.com/Featured-Articles/182922-Growing-Demand-for-Small-Molecule-CDMO-Services

12. http://www.ivtnetwork.com/article/auditing-contract-manufacturers-what-do-you-do-when-contractors-have-terrible-gmp-profiles

13. http://www.cdpr.ca.gov/docs/risk/bmdcont.pdf

14. http://www.asse.org/assets/1/7/safetyaudit-plancondjfearing1408.pdf

About the author

After graduating from Glasgow Caledonian University with a Bachelor of Science degree in Applied Bioscience David spent seven years as a Supervisory Scientist working for Aptuit in Edinburgh before moving to Penn Pharma as Head of Formulation Development in 2009. Here he played a vital part in the design of the high potent Contained Manufacturing Facility (CMF), which won the ISPE Facility of the Year award for Facility Integration (2014). With the acquisition of Penn by PCI Pharma Services in 2013, Dave took on the role of Director, Pharmaceutical Development at the PCI site in Tredegar. In his current role Dave aids clients with Formulation Development, Technical Transfer and Scale-up of solid oral, oral liquid and semi-solid products for clinical trials and/or commercialisation.

After graduating from Glasgow Caledonian University with a Bachelor of Science degree in Applied Bioscience David spent seven years as a Supervisory Scientist working for Aptuit in Edinburgh before moving to Penn Pharma as Head of Formulation Development in 2009. Here he played a vital part in the design of the high potent Contained Manufacturing Facility (CMF), which won the ISPE Facility of the Year award for Facility Integration (2014). With the acquisition of Penn by PCI Pharma Services in 2013, Dave took on the role of Director, Pharmaceutical Development at the PCI site in Tredegar. In his current role Dave aids clients with Formulation Development, Technical Transfer and Scale-up of solid oral, oral liquid and semi-solid products for clinical trials and/or commercialisation.

About PCI Pharma Services

PCI Pharma Services is an integrated full service provider, a proven and trusted partner to leading companies in the global healthcare industry. We offer unparalleled expertise and experience in taking compounds from the earliest stages of development through to successful commercialization, delivering speed-to-market and commercial success for our customers.

Our core services support each stage of the product lifecycle, including drug development, clinical trial supply, commercial launch and ongoing commercial supply. We partner with clients in providing innovative technologies, flexible solutions, and an integrated supply network supporting lifesaving medicines destined to over 100 countries around the world.

We support clients with a dedication to providing the industry’s leading experience, exemplified in our operational flexibility, delivery, and commitment to safety, supported by industry leading technologies and an exemplary quality and regulatory record. This has allowed us to be the partner of choice for leading pharmaceutical companies around the world, operating as a seamless extension of their business.