Novel Nanofiber Membrane To Increase Yield And Purity For Cell And Gene Therapy Applications

By Ian Scanlon, Ben Wallis, Adam Pinnock, Nathaniel Hughes, Eric Schmid, Marc Hummersone, and Bilal Ahmad, Astrea Bioseparations Ltd

Bioprocess adsorbents, both bead- and membrane-based, are limited by capacity, flow rate and pressure drop. These adsorbents are also expensive to manufacture and can easily become unstable under different process conditions (e.g., temperature, pH, etc).

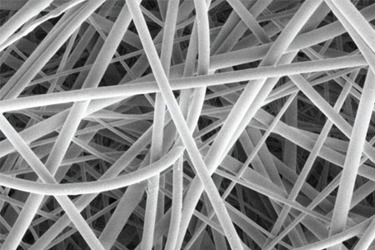

Membranes constructed from electrospun nanofibers have shown great promise when applied to the separation of biological substances, particularly for fragile vectors used in cell and gene therapies. Recently, membrane adsorption/chromatography using nanofibers have shown great promise for use in bioseparations. Such single component nanofibers are superior to single component microfibers, as pore sizes, affinity characteristics, and other performance criteria, can be more precisely controlled.

However, single-component nanofiber structures are often less efficient in terms of stability and time requirements. There is a need to further improve stability of these single-component nanofiber structures and the purification efficiency of biological products.

Here, we demonstrate that AstreAdept™, a novel composite nanofiber material, can bring fast flow rates, increased binding capacities to biological product purification, and ameliorate many of the limitations posed by single-component fiber systems.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.