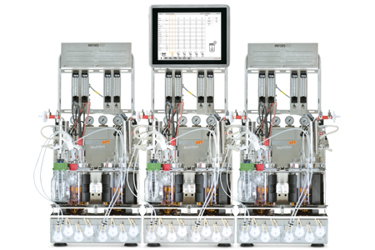

Multifors 2 Bench-Top Bioreactor: Up To Six Culture Vessels On Three Base Units

Source: INFORS HT

Manage multiple bioreactor vessels in parallel while mitigating risks during scale-up.

Increase efficiency during process development and characterization by configuring your Multifors® 2 bench-top bioreactor with the same sensor technology as your production bioreactor systems.

Key Multifors Advantages

- Maximum options while minimizing contamination risks: The magnetic drive system allows for maximum headplate ports and ergonomics while minimizing the contamination risk and wear on components; capable of 1600 RPM operation for extended continuous batches.

- Increase productivity and minimize downtime within existing lab space: Save time, space, and resources with optimized parallel bioprocessing, operating up to 6 Multifors® bioreactor vessels from one touchscreen control. With a small footprint and robust housing, you can make the most of your bench space to increase productivity and minimize downtime.

- Easily scale-up your process: Be prepared to scale-up from the bench using the same sensor technologies as the larger scale bioreactors, delivering comparable data. Optional PAT tools are available to offer a straightforward way of preparing for later production at bench or pilot-scale bioreactors.

- Automate your process development data: Further optimize your process development through automation. eve®, a web-based bioprocess platform software easily integrates with your bioreactors, regardless of the manufacturer, so you can more efficiently control, monitor, and analyze your data.

Product Specifications

- Vessel sizes (and working volumes): 400 mL (115 - 250 mL), 750 mL (180 - 500 mL), and 1400 mL (320 - 1000 mL)