Is Your Bioprocess Facility Truly 'State-Of-The-Art?'

By Maik Jornitz, principal consultant, BioProcess Resources LLC

Scanning announcements of new process and facility investments within the biopharmaceutical industry, you can see that declarations that they are state-of-the-art are becoming more and more prevalent. Diving into what that declaration encompasses often shows that it may not be the case and, typically, the state-of-the-art description is overstretched, if not erroneous.

This article will review what “state-of-the-art” means as well as what is often described as state-of-the-art and what should it really be.

The Definition Of ‘State-Of-The-Art’

The term "state-of-the-art" implies the highest level of development and advancement in a particular field, whether it's related to technology, procedures, techniques, or processes. According to sources like Merriam-Webster, "state-of-the-art" refers to the current level of advancement achieved through modern methods.

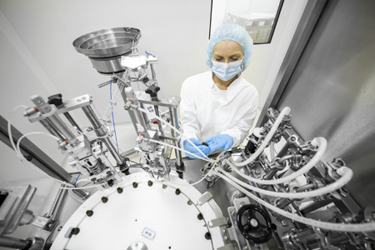

In the context of biopharmaceutical processes and facilities, being state-of-the-art means incorporating the most modern, technologically advanced, and up-to-date practices. This includes using the latest generations of materials, automation systems, and processes. To be considered state-of-the-art, a facility should employ cutting-edge technologies and techniques that represent the pinnacle of development in the biopharmaceutical industry.

The Reality

In some cases, the term "state-of-the-art" may be used loosely without truly reflecting the highest level of technology and innovation. It is important to critically evaluate the claims made about a facility and consider whether it genuinely meets the criteria of being state-of-the-art.

Regarding the use of outdated materials and designs, it's possible that some facilities may still incorporate older technologies due to various reasons such as cost constraints, regulatory requirements, or limitations in the availability of newer technologies. For example, there are still new biopharma production facilities being constructed that utilize epoxy-coated gypsum cleanroom wall materials instead of much more modern and robust UPVC modular wall panels. In such cases, the term "state-of-the-art" might not accurately describe the facility, as it implies the use of the most advanced methods and equipment available.

Moreover, state-of-the-art implies that something is at the cutting edge of technology at a particular moment in time. However, as technology advances rapidly, what may have been state-of-the-art at one point may no longer hold that status in the future. Newer technologies and innovations continuously emerge, challenging the notion of a static state-of-the-art facility.

To mitigate these challenges, it is important to consider the context in which "state-of-the-art" is being used. Evaluating the track record and reputation of the organization behind the project, considering independent assessments and reviews, and analyzing the specific technologies and processes being implemented can help determine whether a facility truly meets the criteria of being state-of-the-art.

Ultimately, the concept of state-of-the-art is dynamic and subject to change. What is considered advanced today may become standard practice tomorrow. It is essential to continually push the boundaries of technology and innovation to strive for continuous improvement in the biopharmaceutical industry. It very much belongs in the same discussion topic basket as aging facilities and the threat of drug shortages due to the breakdown of processes. State-of-the-art needs to hold its promise and should not be used to describe antiquated technologies.

The Motivation To Call Everything ‘State-Of-The-Art’

There could be several motivations for erroneously labeling a facility as state-of-the-art. A few possible reasons could be:

- Marketing and Promotion: Using the term state-of-the-art can create a sense of prestige and attract attention from potential investors, partners, and customers. It may be employed as a marketing strategy to enhance the perception of the facility and generate interest.

- Competitive Advantage: In a highly competitive industry such as biopharmaceuticals, claiming to be state-of-the-art can differentiate a facility from its competitors. Even if the facility doesn't meet the strictest definition of state-of-the-art, using the term may create an impression of superiority and innovation.

- Perception Management: Calling a facility state-of-the-art can be a way to manage external perception and maintain a positive image, including in the eyes of regulators. It may be intended to showcase a commitment to advancement and cutting-edge technologies, even if the implementation may not be as up to date as claimed.

- Limited Awareness or Knowledge: Sometimes the use of the term arises from a lack of awareness or knowledge about the latest technologies or industry standards, as press releases are typically filed by marketing functions, which do not necessarily have all the information needed. It could be unintentional or based on outdated information, where the department releasing the information genuinely believes that it is at the forefront of technology.

It is essential for stakeholders to critically assess and validate the claims made about a facility's state-of-the-art status through independent evaluations, research, and understanding the actual implementation of advanced technologies. This scrutiny can help ensure transparency and accuracy, benefiting both the industry, regulators, and the consumers. This will become more important with new therapies entering the realm of patient care and the discussions of abbreviation of post-approval change rigidity to implement new technologies. If promises or statements are made that do not reflect reality, they will cause more harm than good, as regulators must rely on statements made.

The Ideal

The ideal or optimal state would be to elaborate on the new facility’s attributes. Instead of generically declaring a facility is state-of-the-art, one could describe what technological progress has been made and how these new technologies will support patient safety and access to medicinal products. The ambition of the industry must be to serve its customers, the patients, as best as possible and that can only be done with optimized and new processes. For too long, we have experienced drug shortages because of outdated technology, process and facility breakdowns, or quality observations.

As mentioned, state-of-the-art biopharmaceutical processes and facilities are at the forefront of technology and innovation in the field. They represent the most advanced and cutting-edge methods and equipment available for the development, production, and manufacturing of biopharmaceutical products such as drugs, vaccines, and therapies. For example, new process technologies that have been developed include single-use process assemblies, which can be aseptically interconnected and represent a first barrier to the surrounding environment. These assemblies have not only been extremely helpful as a barrier system but also in avoiding using high levels of energy, water, and labor resources. Such a technology advancement not only benefits the patient but also reduces operating costs and environmental impact.

However, state-of-the-art means also that technological progression does not stand still. In terms of processes, state-of-the-art biopharmaceutical facilities utilize the latest techniques and methodologies to ensure optimal efficiency and quality of the products being developed. This could include advanced purification processes, cell culture technologies, gene expression systems, and bioreactor technologies, among others. These processes are designed to maximize yield, purity, and safety of the biopharmaceutical product.

Automation is another key aspect of state-of-the-art biopharmaceutical facilities. Automation systems allow for highly precise and consistent control over various processes, reducing the risk of human error and ensuring a high level of reproducibility. They also enable continuous monitoring and real-time data analysis, allowing for immediate adjustments to and optimization of the manufacturing process. This leads to improved efficiency, productivity, and quality control. This aspect is especially important for new cell and gene therapies as these require greater automation to lower costs and enhance safety. Moreover, traditional quality control steps to release a batch will not be practical in some of these therapies as the therapeutic product must be administered within an extremely tight time frame. New technologies, like rapid microbial testing, closed processes, process intensification, highly controllable containment, and clean, robust materials, to name a few, are key to enhancing the availability of such therapies.

Overall, state-of-the-art biopharmaceutical processes and facilities are characterized by their commitment to utilizing the most advanced technologies, materials, automation systems, and processes available at any given time. By staying up to date with the latest advancements in the field, these facilities can improve the quality, safety, and efficiency of biopharmaceutical production, ultimately benefiting patients and healthcare systems.

Conclusion

While the term "state-of-the-art" is frequently used to describe new process and facility projects, it is important to approach these claims with a critical mindset. Erroneously labeling a facility as state-of-the-art can stem from various motivations, such as marketing and promotion, competitive advantage, perception management, or limited awareness. By examining the context, assessing independent evaluations, and understanding the actual implementation of advanced technologies, stakeholders, including regulators, can make informed judgments about a facility's status. It is crucial to recognize that the concept of state-of-the-art is dynamic and subject to change as technology continues to advance. Striving for continuous improvement and staying up to date with the latest innovations should be the ultimate goal for the biopharmaceutical industry, especially with new therapeutic developments and approvals.

About the Author:

Maik W. Jornitz is a technical expert with over 35 years of experience in bioprocesses, especially sterilizing grade filtration and single-use technologies, including regulatory requirements, integrity testing, systems design, and optimization. Jornitz has published 11 books, 18 book chapters, and more than 100 scientific papers. He is a member of multiple PDA Task Forces, a former chair of the PDA Board of Directors, and the PDA’s Science Advisory Board.

Maik W. Jornitz is a technical expert with over 35 years of experience in bioprocesses, especially sterilizing grade filtration and single-use technologies, including regulatory requirements, integrity testing, systems design, and optimization. Jornitz has published 11 books, 18 book chapters, and more than 100 scientific papers. He is a member of multiple PDA Task Forces, a former chair of the PDA Board of Directors, and the PDA’s Science Advisory Board.