InSiliCHO: Modeling Cell Line Dynamics For Process Development

Modeling and simulation can be a powerful tool for bioprocess design. We now present InSiliCHO, an open source implementation for in silico simulation of Chinese hamster ovary cells (CHO) and a foundation for future work in DoE tools, active learning and more.

Why Simulate?

A good process model:

- helps researchers understand and predict bioprocess behavior during scale-up;

- allows qualitative exploration of system dynamics by testing control strategies quickly and cheaply;

- provides more detailed understanding of process behavior than an empirical response surface derived from Design of Experiments (DoE).

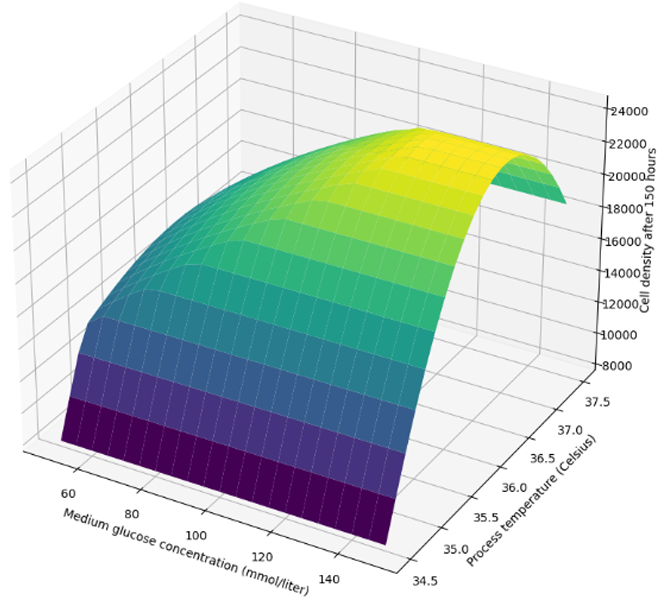

See here for a comparison of process dynamics as described by a typical response surface as obtained with DoE (left), versus a response surface from a process model (right).

DOE Response Surface

Mechanistic Model Response Surface

The figures show cell density after 150 hours for different glucose concentrations in the starting medium and different process temperatures. While the DoE model gets the relationships directionally correct, it misses details that the process model is able to capture.

Foundations

We implemented the model described in Möller et al., 2020 [1]. This model describes the evolution of cell density, glucose, glutamine, lactate, ammonia and monoclonal antibody (mAb) concentrations. It encodes sensitivity of growth and death rates to the various chemical species, lactate metabolic shift (dependent on glucose concentration), and the inhibitive effect of ammonia on antibody production. The dynamics of the model are based on known characteristics of CHO, and the default parameters used in the model were chosen to reconstruct experimental data with good fidelity.

[1] Möller, Johannes, Tanja Hernández Rodríguez, Jan Müller, Lukas Arndt, Kim B. Kuchemüller, Björn Frahm, Regine Eibl, Dieter Eibl, and Ralf Pörtner. “Model Uncertainty-Based Evaluation of Process Strategies during Scale-up of Biopharmaceutical Processes.” Computers & Chemical Engineering 134 (2020): 106693.

Try It!

You can try the model in our app. Use the sliders to adjust parameter values and initial conditions. The process dynamics are simulated in real time. The experimental data on which the original model was fitted is also visualized.

A fun thing to try is to optimize control and initial conditions for final mAbs concentration (can you get above 1000 mg/L?). The model can also be installed locally as a Python module via pip.

What's Next?

- DoE: We use InSiliCHO to run Design of Experiment campaigns (DoE) in silico. We learn the cost and complexity tradeoffs of different experimental designs. This helps form priors on what might be observed in different experiments. And ultimately this technique helps us identify the most effective set of experiments to run in vitro.

- Fitting: The parameters of the model can be fine-tuned in order to match experimental results for a specific project. By doing so, the same model structure can be used to simulate and compare different cell lines and reactor setups.

- Active learning: After fitting the model, we estimate uncertainty about model parameters in the system (such as growth rate). Together, the model and these uncertainty estimates can be used to decide which experiments to run next. The purpose here is to run experiments for model improvement - which is different from the common industry approach of running experiments to optimize a quality metric.

- And more: Scale Up, CHO Model Improvements, and Modeling Other Platforms