Improving Digital Integration Between Biomanufacturers & Partners

By BioPhorum

Over the past decade, biopharmaceutical supply chains have become increasingly complex, often involving multi-enterprise manufacturing collaborations and partnerships to supply lifesaving medicines to patients. This evolution beyond the single-source manufacturing model is driving an industry need for standardized approaches to data integration between organizations to support agile and predictive supply chains. Initial projects to improve digital collaboration have often deployed bespoke point-to-point solutions between sponsor and contract organizations.

However, without standardization, data and data structures are different from each source, vary over time (over product life cycles), and are difficult to use for the advanced purposes we need. It is important for the industry as a whole to simplify the complex diversity of the current landscape.

This article describes the current state of digital integration between sponsor and contract organizations in the biopharmaceutical industry. It characterizes the problems that need to be addressed and outlines the benefits that would come from better digital integration. A simple maturity model gives a high-level overview of increasingly sophisticated patterns of data and information exchange between sponsors and contract organizations. It also reveals the need for layers of alignment in any contractual relationship. It suggests that identifying process touch points and data needs is the business-led foundation for any digital integration design.

To supplement the creation of this vision and ensure the ideas reflect a breadth of views across the industry, biomanufacturers, contract organizations and relevant IT solution providers – 31 participants from 22 organizations – completed a detailed survey during August and September 2022. This asked participants which broad process areas were the highest priorities for investment in more advanced digital integration with external organizations.

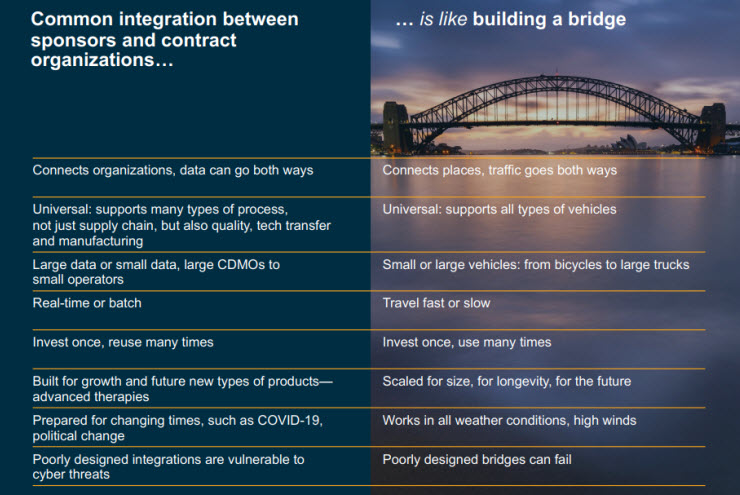

Vision: It’s Like Building A Bridge

Creating common integration between sponsors and contract organizations is like building a bridge (see Figure 1). Just like a bridge connects places and traffic goes both ways, our vision solution must connect organizations with data going both ways.

Figure 1: Bridge analogy

BioPhorum’s Digital Plant Maturity Model (DPMM) is used across the industry to assess manufacturing plant maturity, identify capabilities needing development, create strategic plans and road maps, influence suppliers, and develop human resources competency and development frameworks. All of this relates to manufacturing within a single organization. But what does digital maturity look like when there is a partnership between sponsors and contract organizations?

The DPMM is still the reference point for the manufacturing plants in each organization, but for our processes to achieve digital maturity we also need to consider many collaboration points between organizations.

The DPMM requires digitization, common processes across products, and aggregated data to make predictive and adaptive approaches possible. The same should be true of a digital maturity model for interactions between sponsor and contract organizations.

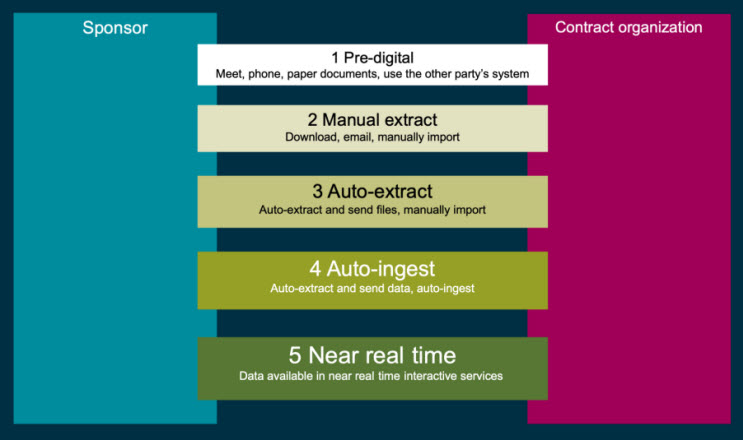

The DPMM describes five levels of maturity: pre-digital plant, digital silos, connected plant, predictive plant, and adaptive plant. It seems appropriate to classify the maturity of the interactions between organizations in a similar way (see Figure 2).

Figure 2: Patterns of maturity in digital integration

Over the past decade, biopharmaceutical supply chains and manufacturing networks have become increasingly complex, often involving multi-enterprise manufacturing collaborations and partnerships to supply lifesaving medicines to patients. The trend is similar to some other industries where 80% of the value of products is now produced by external partners.

This evolution beyond the single-source manufacturing model is driving industry to pursue more standardized and digitized approaches to collaboration. The goal is to manage and improve processes and support agile supply chains through the bidirectional sharing of data and process knowledge. More reliable and timely information will support supply visibility, continuous process verification, analytics, and predictive capabilities while ensuring product quality.

Sponsors are working with more contract organizations and in deeper collaborations. Vice versa, contract organizations are working with more sponsors. There is often a mismatch in digital maturity: a contract organization may be working with a small startup biotech with almost no IT capability; conversely, a sponsor may choose a contract organization with good biotech capability but limited IT. The mismatch means that there will always be some diversity in how we interact.

The situation is compounded by issues such as:

- The expectation that there should be the same level of visibility and sophistication of decision support when working with external organizations.

- When information needs to leave an enterprise’s internal systems of record, it is typically conveyed to outside parties in a highly manual and unstructured manner.

- Industry has developed point solutions to meet the specific needs between two parties.

- There is limited opportunity to reuse the technical investment because capabilities are siloed to working with a particular partner, rather than being flexible.

Types Of Digital Communication Between Sponsors And Contract Organizations

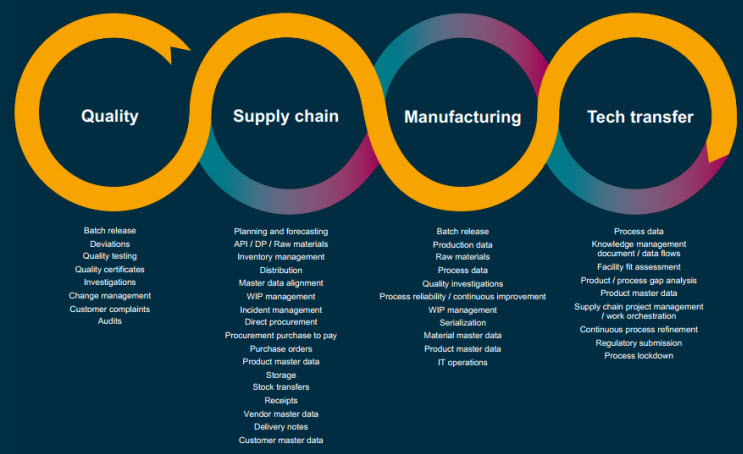

There are four key areas where accurate and timely data exchange is fundamental to

success for sponsor and contract organizations:

- Quality

- Supply chain

- Manufacturing

- Tech transfer

Digital integration in these areas supports closer ways of working within each partnership. Sponsors have increased transparency across the end-to-end life cycle of a product and data passing from sponsors allows contract organizations to plan better and execute more efficiently.

Examples of the types of data exchange in each process area are shown in Figure 3. The items in each broad process area are shown in ranked order of importance revealed by questions in the survey, which asked, “Which types of data exchange is it most important to improve?”

Figure 3: Types of data exchange. Click on image to enlarge.

Figure 3 makes clear that some items are specific to one process area, whereas others are interrelated (e.g., the themes of batch release, master data, and investigations). This helps establish the case for a common approach across different audiences rather than point solutions.

It is helpful to create an end-to-end value chain chart that in one big picture shows, in parallel, the contributions of the sponsor and contract organization for a particular set of partnerships throughout the life cycle. This reveals all the touch points between the organizations, and each touch point can then be analyzed to discover the current and preferred levels of digital maturity.

One biomanufacturer case study revealed 35 digital touch points with their contract organizations, mostly at maturity levels 1 to 3 (pre-digital, manual extract, or auto-extract), prompting an analysis of the weak points and beginning the process of prioritizing some for uplift to maturity level 4 (auto-ingest).

Benefits Of Better Digital Integration

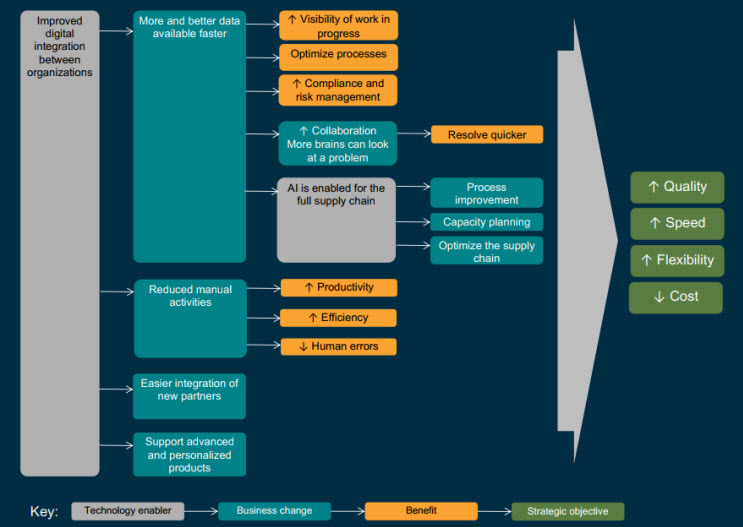

Improved digital integration between organizations is for a purpose: we want to enable business improvements that bring benefits that support the strategic objectives of our organizations.

Figure 4 shows that improved digital integration between organizations leads to four main business improvements:

- More and better data available faster

- Reduced manual activities

- Easier integration of new partners

- Support advanced and personalized products

All these business improvements translate into support for the strategic objectives of biomanufacturing organizations in terms of quality, speed, flexibility, and cost.

Figure 4: Benefits of improved digital integration between organizations. Click on image to enlarge.

Each organization, whether a sponsor or contract manufacturer, brings their own data infrastructure, systems, and practices into an engagement.

To establish the best approach for collaboration, each organization should assess and share its requirements and align on digital capability and strategy. The goal is not always Level 5. The digital maturity level targeted for each type of communication depends on:

- the business needs driving the data exchange

- the volume of transactions

- how and when the data will be used and for what purpose

- the maximum capability of each party

- the priority of the relationship.

It may be necessary to communicate similar data with a range of partners but using different levels of communication according to what they are able to do. Collaboration solutions must accommodate partners at the lowest maturity level and be able to evolve as organizations mature.

The survey had three main findings about the aspirations the participants reported for digital maturity in the broad process areas:

- The main aspiration in most areas is auto-ingest.

- Near real-time is a growing aspiration for supply chain and manufacturing.

- The aspiration for tech transfer is more mixed – a little less sophisticated.

Where a clear understanding of maturity level requirements exists, partner organizations are better positioned to define a vision for collaboration between organizations. Digital road maps and timelines to implement higher maturity levels can then be embedded into the relationship. It is unlikely that all data requires the same maturity level, so the expectation should be for a mixed model of data exchange appropriate to the intended use of the data.

Whatever the maturity level, partners need to agree on the structure, content, and labeling of the data being exchanged, and changes must be carefully managed over time to ensure work processes and applications using the data are not broken when a change occurs.

Principles For Digital Integration Between Sponsors And Contract Organizations

The goal of increased digital maturity in the interactions between sponsors and contract organizations requires a framework of principles to guide successful implementation (Figure 5).

Figure 5: Principles for digital integration

A key element for successful long-term collaboration between sponsors and contract manufacturing organizations (CMOs) is trust. Building that trust requires transparency and equitable information sharing. CMOs must provide access to the information and data that sponsors need to run their businesses effectively. Meanwhile, sponsors may need to provide technical expertise and knowledge to the CMO to ensure they can be successful, while allowing them the latitude to work within their own processes and structures.

Other principles include:

- Do not just automate emails, design an effective overall process.

- Document the purpose of each data point.

- Work with existing systems.

- Support varied levels of digital maturity.

- Contract for transparency, agility, and the ability to move forward.

For effective digital communication between sponsors and contract organizations, there needs to be a lot of alignment: legal, contractual, project execution, technical transfer, technical structure, and use. The main focus is on four layers of technical alignment:

- Process and required data

- Data structure

- Information container

- Secure transport mechanism

To avoid point solutions, we would want to use the same secure transport mechanisms, the same data load containers, and similar data structures wherever possible. The options and detail of each layer can be considered separately and then assembled in an appropriate way for each integration point with a particular partner, respecting their level of digital maturity. Using the principle of decoupling, the effect will be common data exchange, even though the choice of mechanism in certain layers could vary from partner to partner.

Issues to consider include process and required data, data structure, the information container, and secure transport.

Conclusions

Collaboration between sponsors and contract organizations has not reached digital maturity. There are some bespoke point-to-point solutions, but there is little standardization. Demands for improvement with the narrow perspective of particular partnerships have paradoxically increased the overall complexity and compounded the problem for biomanufacturers and their partners. To achieve efficiency, agility, visibility, and the benefits of advanced analytics, we need improved and more standardized digital integration between organizations.

The challenge is now for biomanufacturers, contract organizations, and IT solutions providers to work together to make this vision a reality. We must transform paper into data, records into actionable insights, and contracts into partnerships. For the industry as a whole, we must achieve the benefits of cost, speed, quality, and flexibility that will come from digital maturity. And when we collectively achieve these goals, we will accelerate the nobler and more important goal of bringing new, life-changing, quality therapeutics to the people who need them around the world.

This article is a summary of a recent BioPhorum publication on the topic. To read more, check out the full report in Vision for digital maturity in the integration between biomanufacturers and partner organizations.