Hyper-Productivity In Your mAb Purification Step

Modern chromatography resins and systems have continued to improve over the past fifty years. However, challenges related to resin designs, columns, and processes keep the actual process performance below theoretical limits. Cylindrical formats, non-ideal packing, and hardware limit the ease of use and flexibility in biomanufacturing. The recent improvements in chemical stability and dynamic binding capacity (DBC) of Protein A-based affinity resins have only allowed incremental increases in the productivity (g/L/h) of monoclonal antibody (mAb) capture processes. The limited mechanical stability of packed beds in columns is a particular challenge. It forces resin manufacturers to compromise the mass transfer offered by smaller, and sometimes less rigid, particles against the better pressure-flow properties of larger, more rigid particles.

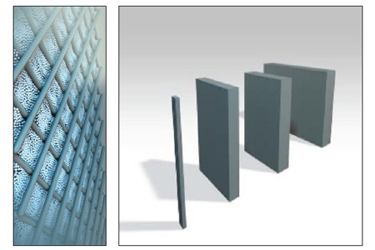

The internal lattice structure of Chromassette supports the resin bed, allowing high flow rates for conventional, and the more challenging smaller and softer resins. Chromassette cassettes can be packed with any chromatography resin and scale-up is linear as the rectangular pre-packed cassettes offer the same bed support at both lab and manufacturing scales.

In this study, a high capacity prototype 30 μm Amsphere Protein A resin was packed in Chromassette, which enabled the process to reach ~200 g/L/h. This application note provides details of the process developed including data on throughput and product quality. Scale-up of this technology and the process is also discussed.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.