Frontiers In Digital Bioprocessing: Modular Plant Automation And Cloud

By René Reinbigler, Head of Software Analytics & Sensors Integration and Lukasz Paciorkowski, IT Architect for Cloud and new Business Models

Digital innovation is a critical enabler to meet growing market expectations and adapt to the paradigm shift required by the biomanufacturing facility of the future, an ecosystem of intensified, connected, and continuous processing seamlessly coupled with uninterrupted data acquisition and analysis. Today, to embrace this change, biomanufacturers are evolving their operations to address unprecedented market trends and new business drivers.

Among today’s market trends, there is fast market growth – mainly fueled by global demand for new therapeutics. In parallel, new product modalities are emerging, such as cell and gene therapies, mRNA with the potential to change the market demand. At the same time, globalization is adding uncertainty to existing clinical and regulatory risks, along with the constant need for sustainability. Lastly, biopharmaceutical companies will also need to respond to growing pressure to deliver by increasing production capacity and improving supply chain resilience.

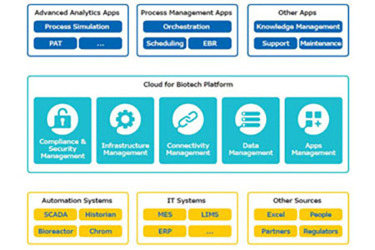

Both cloud and modular plant automation concepts focus on flexibility and automated deployment, are data driven and enable modularity. As the biopharmaceutical industry is embracing digital transformation and thus evolves in its digital maturity, these future-ready concepts will play a leading role in the shift toward bioprocessing 4.0.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.