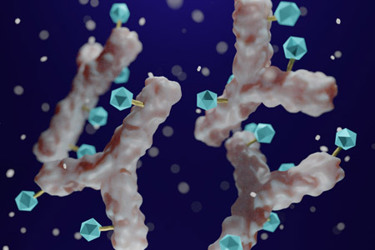

Eliminating Downstream Bottlenecks And Boosting Productivity In Antibody-Based Therapies

By William Barrett, W.L. Gore; and Chase Snyder, AGC Biologics

AGC recognized a bottleneck in downstream protein purification processing as a key challenge. The R&D center was achieving high titers in the cell lines it produced but was limited by a facility footprint monopolized by large, fixed-bed columns in its post-consumer resin (PCR) environment. AGC needed to improve upon the time those devices required to purify even small amounts of drug product.

Gore’s rapid cycle, ePTFE membrane solution provides a binding capacity advantage at high flow rates and improves the speed of purification versus more traditional, packed bed resin-based technology. Resin chromatography is driven by intraparticle diffusion: the protein of interest must diffuse into agarose resin beads, where it then interacts with the ligand of interest via affinity binding, hydrophobic interactions, ion exchange, or a mixed-mode modality. Gore membranes, meanwhile, utilize a combined convective and diffusive flow, which allows for much faster mass transfer, resulting in a significantly higher volume of drug product (e.g., in grams) processed per liter of chromatographic media, per hour, enabling a single-use option in Protein A purification.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.