Crystallization Process Development: Ramping Up Bench-Scale Control For Manufacturing

By Hayley Reece, Executive Director, Technical Services, and Craig Callahan, PhD, Project Scientist 4, Crystallization Process Development, Cambrex

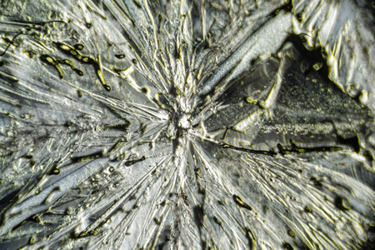

Crystallization is an essential element of drug development, whether it is performed during formation of an API or as a means to purify intermediates. Since physical structure and biological activity are directly linked, controlling the physical form of a compound is paramount to a final drug product’s quality and effectiveness. Drug manufacturers must also demonstrate to regulatory authorities that the physical properties and chemical purity of a drug substance are well understood and controlled. Therefore, the development of a robust crystallization process is an integral part of drug development.

Before scientists can manipulate various critical process parameters to yield the optimal result, they must have an in-depth understanding of the thermodynamic and kinetic processes affecting the product material. At Cambrex, we leverage our expertise to bridge the gap between the bench and manufacturing, providing controlled crystallization processes to help our clients achieve clinical delivery timelines.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.