Creating A Drum Transfer Solution

By Scott Patterson

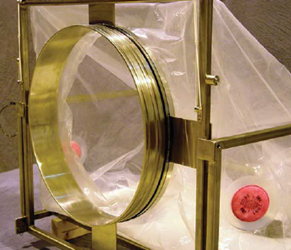

One of the simplest, most convenient and most cost-effective ways to ship, receive, and store bulk powder ingredients, including active pharmaceutical ingredients (APIs), intermediates, excipients, and ingredients for buffers and media, is in drums. The contents of these will need to be transferred before use, and this process can be challenging. Integrated drum transfer solutions make the process simpler, cleaner, and faster, improving safety for both workers and patients, as well as protecting any remaining ingredients for storage.

The Challenges Of Drum Transfer

A great many powder ingredients for pharmaceutical manufacturing are delivered in large drums, from media ingredients to the APIs themselves. The ingredients then need to be taken out of the drums and transferred into other containers for the next step in their use – this includes:

- Milling — sifting or particle size reduction

- Subdividing — dividing into measured amounts

- Repackaging — for customer use

- Charging —– transferring to vessels for the next step of processing

Whatever the application for powder transfer, the fi rst challenge faced is handling the drums. Full drums can be very heavy to lift, and may need to be lifted high to charge containers or equipment. Unless drums are handled carefully, this puts workers at risk of injury. Manual handling can also be a slow process, which can cause delays.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.