Continuous Flow Manufacturing Of Pharmaceutical Ingredients

While batch process chemistry remains the standard in the pharmaceutical industry, a clear increase in continuous flow processes has emerged over the past decade thanks to the commercialization of preparative flow reactor units. In a recent survey questioning both CDMOs and major pharma companies, the majority anticipates that in the next 15 years, there will be a shift from batch to flow to up to 25% of the total portfolio.1 Moreover, with the release of the draft guidance “Quality Considerations for Continuous Manufacturing” in February 2019, the Food and Drug Administration (FDA) is determined to promote the implementation of continuous manufacturing processes with the main objective to improve product quality, which is the main underlying cause of drug shortages and recalls.2

In the future, a strong growth is anticipated for continuous flow manufacturing of active pharmaceutical ingredients as it offers a number of important advantages over traditional batch manufacturing in terms of quality, safety and sustainability of the overall process.

FOCUS ON SAFTEY

The enhanced safety of chemical processes is often the driving force to switch from batch to flow processing. At Ajinomoto Bio-Pharma Services, we have a long-standing successful track record of assisting customers with their hazardous chemistry needs. Recently, we have transformed a diazomethane batch process into a continuous flow process, which enables us to supply the growing demand of at least 500 tons/year of a specific product.

Compared to batch chemistry, the reaction volumes in flow chemistry are much lower and inherently represent a lower safety risk upon the unlikely event of a runaway reaction. Furthermore, the heat-transfer in continuous flow installations is several orders of magnitude greater then what is usually observed for traditional batch process vessels. Consequently, the heat that is generated upon chemical reaction is dissipated swiftly and allows superior control of the manufacturing temperature to stay within safe operating conditions.

Another advantage is the opportunity to combine various process streams at any point of the chemical reaction. This permits the generation of unstable intermediates and in situ prepared hazardous reagents, which are immediately consumed upon combination with a subsequent process stream prior to the formation of side products.

FOCUS ON QUALITY

Concerning patient safety, drug regulators require active pharmaceutical ingredients to meet high quality standards and prescribe manufacturers to implement control strategies at each stage of the production. The unrivalled control of the reaction profile in flow processing translates in consistent purity and quality of the target material.

The superior heat and mass transfer form the basis for the improved regulation of the set of reaction conditions. In batch processing the heat transfer surface area usually drops by an order of magnitude upon scaling from laboratory to pilot. As a consequence, the ability to evacuate excess heat from the reaction mass is hampered and the reaction mixture can feature local hot spots ultimately leading to unwanted side reactions and degradation of the target material. While the upscaling of continuous flow reactions also suffers from a reduction in heat transfer area, the drop is less severe as the initial surface area to volume ratio is much larger compared to the ratio in batch reactors.

A frequently encountered issue that impacts product quality upon upscaling in traditional batch processes is inefficient mixing. Similar to heat transfer, the mass transfer declines when traditional batch processes are scaled and while there are several engineering and modelling tools to optimize mixing performance, the plethora of parameters impacting the latter make predictions uncertain. In contrast, mixing in plug-flow (tubular) reactors is more straightforward and mass transfer can relatively easy be kept constant throughout the development of the continuous manufacturing process at different scales.

The benefits of the superior reaction control are exemplified in a recent example where we successfully optimized the selectivity of a reaction with a polyunsaturated starting material. Conducting the reaction for a shorter timeframe at higher temperature followed by rapid cooling of the reaction mixture, hampered the generation of overreaction side products in which multiple double bonds are modified.

Continuous flow chemistry set-ups are particularly well-suited for automation and quality-by-design principles. In-line process monitoring and PAT tools can instantly detect process deviations and automatically divert any nonconforming material without affecting the rest of the batch ultimately leading to high quality material.

Another important aspect regarding continuous processing is that the equipment is designed to manage process needs, while in traditional batch chemistry, the chemistry is often customized to fit in the available plant. In multipurpose pharmaceutical manufacturing equipment, contamination of different products is managed by stringent changeover procedures. Given the fit-for-purpose design of the continuous process equipment, and the relatively low cost for the reactive parts in the setup, dedicated or single-use coils and reactors can be considered, eliminating contamination hazards.

Finally, multi-stage continuous processes can circumvent the need to store sythetic intermediates hence avoiding degradation and other stability issues. Furthermore, concomitant with the above, the net working capital of multi-stage continuous processes is less compared to batch processes.

FOCUS ON SUSTAINABLE MANUFACTURING

Continuous processing is considered a key technology for green chemistry. The superior mixing and heat transfer enables chemical reactions to be carried out more concentrated or even in the absence of any solvent3, thereby significantly minimizing waste. Associated to the latter, continuous flow processes often display an enhanced productivity versus the respective batch process counterparts. Furthermore, flow processing can further decrease solvent consumption by applying in-line extraction techniques (eg. Counter current extraction) that typically operate with less solvent compared to batch extractions.

In addition, continuous flow chemistry expands the chemical toolbox with higher temperature and pressure windows in comparison to traditional batch chemistry. The broadened chemical window together with the decreased risk upon use of hazardous reagents, empower shorter synthetic reaction schemes and benefits the purity and yield of certain reactions, thereby reducing raw and auxiliary material requirements. In addition, fully in line with green chemistry principles, continuous flow processes exhibit lower production costs due to the smaller footprint and decreased energy consumption of the set-up.

Continuous flow chemistry also offers the opportunity to use alternative forms of energy to promote chemical reaction. Whereas traditional chemistry relies on thermal energy, continuous flow enables the use of electricity and light.

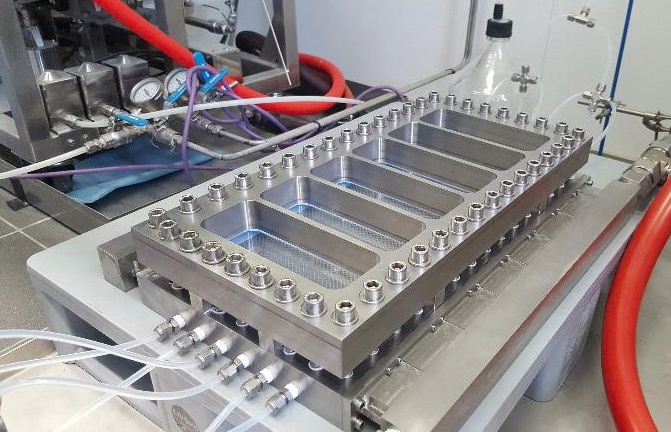

While in the past 15 years, numerous scientific publications have emerged showcasing the synthetic potential of photochemical reactions, but hitherto upscaling has remained an engineering hurdle. Recently developed linear scalable photoreactors like the HANU plate reactor are an effort to overcome this issue.4

FOCUS ON SPEED

The pharmaceutical industry has continuously focused on speed to market. The faster a given product reaches the market, the sooner development costs are recovered which benefits the long term profitability of the innovator company.

Continuous manufacturing can significantly contribute to speeding the development of a particular project. Depending on the required volumes, the same continuous flow installation can be used to manufacture larger amounts simply by running the setup for an extended time, a process often denoted as scaling-out. Furthermore, the scale-up of continuous processes is often straightforward and both footprint and capital expenditures are lower compared to batch processes. As a consequence, the commissioning of novel continuous flow reactor train is markedly faster than that of a new batch chemistry unit.

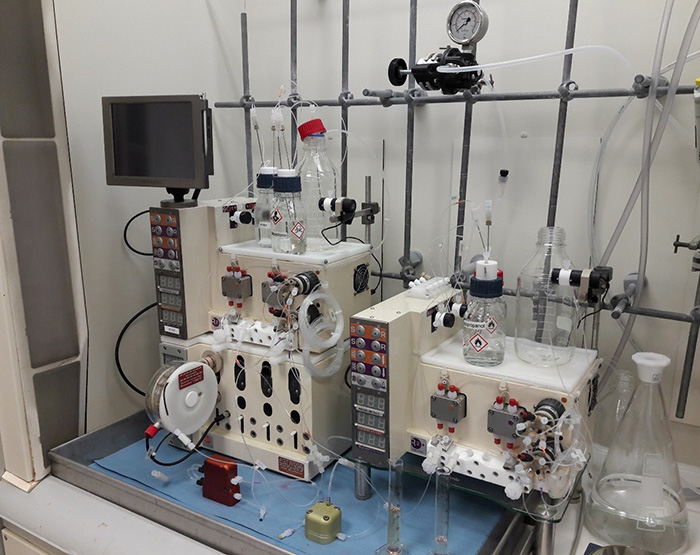

As an experienced CDMO for small molecules and hazardous chemistry Ajinomoto Bio-Pharma Services has made significant investments in to its continuous flow equipment and technical staff. Additionally at the same facility, Ajinomoto Bio-Pharma Services implements or develops new equipment in order to continuously improve processes or to tackle scale up issues for its customers. This includes slurry compatible plug flow reactors, immiscible liquids reaction scale up, inline degassers, counter current extractors and the co-developed HANU (photo) flow reactor.

By selecting a CDMO that possesses extensive flow chemistry experience and a structure that meets your production, one can be more prepared for the the ebbs and flows of small molecule synthesis.

References:

- Org. Process Res. Dev., 2018, 22 (9), 1143-1166, DOI: 10.1021/acs.oprd.8b00160

- https://www.fda.gov/regulatory-information/search-fda-guidance-documents/quality-considerations-continuous-manufacturing

- ChemSusChem., 2013, 6(12), 2220-2225, DOI: 10.1002/cssc.201300684

- www.creaflow.be