Assessing The Implementation Of Periodic Counter Current Chromatography As A Solution To The Protein A Capture Bottlenecks And First Step Towards DSP Continuous Manufacturing

Antonio Ginés García Saura, AGC Biologics and Ingrid Long, Cytiva

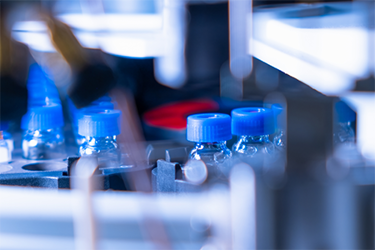

Protein A capture has long been a critical step in monoclonal antibody purification, yet traditional batch chromatography increasingly creates bottlenecks due to high resin costs, inefficient utilization, and large facility footprints. Periodic Counter-Current Chromatography (PCC) offers a transformative solution, enabling continuous loading across multiple columns to maximize resin capacity and significantly boost productivity. Experimental applications of PCC to fed-batch and perfusion processes demonstrated step yields and product purity comparable to batch methods, while achieving up to 81% higher specific productivity and reducing resin requirements by as much as 92%. These improvements translate into substantial cost savings and sustainability gains, without sacrificing buffer efficiency or scalability. Advanced resins like MabSelect SuRe 70 further enhance performance, supporting shorter residence times and high-flow operations under acceptable pressure limits. With strong regulatory support from FDA and ICH for continuous manufacturing, PCC represents a strategic first step toward fully integrated continuous downstream processing. For organizations seeking to overcome capture bottlenecks and accelerate biologics production, PCC delivers a compelling combination of efficiency, quality, and compliance.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.