After Decades Of Biomanufacturing Workforce Development, What's Next?

By Kamal Rashid, Ph.D., International Biotechnology Associates

How can we expand the workforce to support the growing biomanufacturing industry?

It’s a question I have been answering for almost 40 years

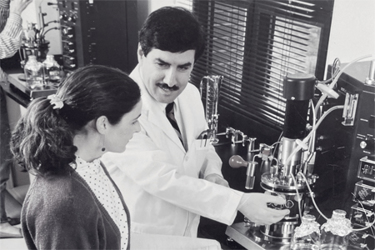

From those pioneering days at Penn State in the 1980s, when we created the first hands-on bioprocessing workforce training programs in the country, to the exponential growth of the biotech industry since, companies have struggled to find qualified workers. To close that workforce gap, we need to leverage the lessons from successful biomanufacturing training programs and consider new approaches to communicate the breadth of opportunities available in this important industry.

Let’s Align

Biopharmaceuticals are the fastest growing sector of the human therapeutics market. More companies are biomanufacturing more products than ever before, which means they need more workers. We see growth in traditional biologics, as well as new classes like cell and gene therapies, bi-specific antibodies, antibody-drug conjugates, immunotherapies, and mRNA vaccines.

Outsourcing to CDMOs adds complexity — these service providers need a workforce capable of handling different processes and rapidly switching between processes based on customer demands. There’s also constant innovation in laboratory equipment to improve existing processes and enable the manufacturing of new classes of biologics.

Taken all together, this means the industry needs greater capacity for ongoing training and retraining of existing workers. To meet this challenge, the overall capacity of workforce development programs needs to align with the distribution of headcount in a biomanufacturing company. While companies always have needs in QA, QC, or R&D labs, the vast majority of their employees are in the manufacturing suites and related support processes. The greatest focus should be on workforce development programs emphasizing hands-on biomanufacturing readiness.

A multilevel workforce development approach begins in high school. What used to be called trade schools in the United States are now typically known as vocational technical high schools. They have a long and successful history of preparing students for hands-on careers in traditional sectors like electrical, carpentry, plumbing, automotive, IT networking, food service, and others. Today, biotechnology programs already in vocational high schools should be expanded and aligned with industrial partners wherever possible.

For too long, biomanufacturing companies have required bachelor’s degrees for nearly all of their jobs, even entry-level positions. This is a mistake. The truth is that the entry-level or even mid-level work in biomanufacturing suites does not require a four-year degree. What it demands are reliable people who are adept at hands-on work, comfortable working in teams, and who can faithfully follow standard operating procedures (SOPs).

There can be a direct pathway from high school to biomanufacturing work if we invest more in the high school vocational schools and if biomanufacturing companies partner with these better focused programs. Improved outreach to high school students, counselors, and families would help demystify the industry and shatter the perception that biotech companies — or CDMOs — are filled only with advanced scientists. We need to work to promote a greater awareness of the careers available in biomanufacturing.

Two- And Four-Year Programs

Community colleges also have a greater role to play in this effort, with a mix of certificate and two-year degree programs focused on specific skills. Additional modules of education and training after high school can enable traditional students to enter the industry at a higher level. Perhaps more importantly, community colleges can help adult learners with no prior experience or relevant education who want to transition their careers into the biomanufacturing space.

For a best practice example of the potential impact of community colleges in this field, people should look to the great success of the biotechnology program at Solano Community College in California, founded and led by Jim DeKloe.

Four-year undergraduate programs in the life sciences can also assist in integrating several biotechnology courses and hands-on biomanufacturing laboratory experiences. This would give graduates exposure to the science and methods used to design, validate, scale up and produce biologics and help them get on a rising career track within a biopharma or service provider, perhaps starting in manufacturing or one of the laboratory support functions.

What We’ve Learned

Regardless of the level of the biomanufacturing program, hands-on experience is essential. There is no substitute for having students working with real equipment, doing projects that reflect the actual tasks they would be expected to perform in a cGMP environment. These lab experiences should be closely integrated with classroom lectures and discussions.

While delivering some of the lecture content remotely is happening widely and with reasonable success, I believe the ideal condition is for the classrooms and laboratories to be in the same facility so the information discussed in lectures can be translated quickly into action in the lab. That is the essence of learning by doing.

From a design perspective, bench-scale laboratories are sufficient for nearly every program. Much can be accomplished at the benchtop as students learn to take cells from frozen stock to a T-flask, to a benchtop bioreactor, and then downstream through a range of operations. Building a bench-scale facility has far lower capital costs, so this would enable more centers to be built or for programs to be integrated into existing academic facilities.

Flexibility is now a core competency. Over time, titers have improved significantly, and more precision therapeutics are becoming a reality. While there will always be a need for large-scale production of blockbuster biologics for large populations, much of the future of biomanufacturing is trending toward smaller batches of an increasing number of products.

Furthermore, outsourcing is growing significantly, with CDMOs requiring employees with skills across upstream and downstream processes and the ability to use different expression systems and technology platforms.

Historically, biomanufacturing companies have relied on their internal training programs to bring new hires up to speed on the basics and to cross-train existing employees. By expanding biomanufacturing programs at all levels of our educational establishment, we will broaden the pipeline and deliver foundational training in settings that emulate cGMP environments. Moreover, we can allow students to take on new challenges, develop new skills, and learn from their mistakes without putting actual product at risk.

The formula for success in these efforts requires a three-way partnership among academia, government, and the bio-based industry. I believe academic institutions are the proper place for these programs, not stand-alone centers. Academia is the seat of research and learning, where faculty understand how to share knowledge. State and federal governments can help fund educational and training programs and provide tuition assistance for income-eligible students and displaced workers seeking retraining. The industry can partner with schools to provide subject matter experts and industrial-grade laboratory equipment to enhance the programs.

It was only 1982 when the FDA approved the first recombinant drug (insulin). Given the relativity of time, 1982 seems like yesterday and also like ancient history to me. So much has changed in 40 years. What remains a constant, however, is the need to expand our collective efforts in workforce development.

About The Author:

Kamal Rashid is the founder of the consulting firm International Biotechnology Associates. In an academic career spanning four decades, he has led bioprocessing academic and workforce development programs at Penn State, Utah State University, Worcester Polytechnic Institute, and the Albany College for Pharmacy and Health Sciences.

Kamal Rashid is the founder of the consulting firm International Biotechnology Associates. In an academic career spanning four decades, he has led bioprocessing academic and workforce development programs at Penn State, Utah State University, Worcester Polytechnic Institute, and the Albany College for Pharmacy and Health Sciences.