Achieving Flexibility In RNA Drug Manufacturing With Microfluidics

By Sung-Hye Grieco and John Stubenrauch, Nutcracker Therapeutics

RNA therapies have, undeniably, gained attention in recent years from drug developers and the general public. With the success of mRNA COVID-19 vaccines, this field has proven its ability to make a positive impact on global health, leading to increased interest and growth in RNA therapeutic development.

Finding an effective way to scale manufacturing is critical to this growing area of medicine in an effort to provide support across all stages of research and production. In fact, a growing number of organizations have already realized the technology to accomplish this.

By using a microfluidics-based approach to RNA therapeutics manufacturing, researchers can efficiently discover and develop a pipeline of therapies for a wide range of indications. In some cases, the same RNA therapeutics manufacturing platforms can be quickly scaled up to meet the increase in demand. This manufacturing flexibility may pave the way for the future of RNA therapeutics.

Current Landscape Of mRNA Manufacturing

Adjusting the scale of manufacturing for different stages of drug development is a common challenge, and the field of RNA therapeutics is no exception. The fundamental differences in the design of manufacturing platforms at different scales present the need to redesign processes to fit the new platform as production increases. For RNA therapies, this means transitioning from plate-based assays to flasks and onto bioreactors — and spending time and resources on process optimization for every new mode of production.

Ironically, this limits the efficiency and flexibility of scale for a modality whose main advantages are precisely efficiency and flexibility. Researchers in the discovery and preclinical stages need the ability to manufacture high-quality RNA therapies in small quantities and to easily transition to larger scales as their therapeutic progresses through the pipeline.

A number of organizations with RNA therapeutics are developing ways — both in process and in technology — to add flexibility and to minimize the footprint of RNA manufacturing and, therefore, to expand the range of scale in which these therapeutics can be produced. BioNTech, for example, has created a modular, shippable manufacturing facility known as the BioNTainer. These modules are essentially portable, high-tech cleanrooms that can be set up easily with a few resources, improving accessibility to RNA therapeutics in low-income countries. And Quantoom Biosciences has created an automated RNA production technology line, called Ntensify, with a variety of unit sizes meant to meet the scale needs of different stages in the drug development process.

Meanwhile, other groups, including Nutcracker Therapeutics, saw microfluidics as an interesting solution to create right-sized manufacturing processes optimized to RNA’s unique properties.

Applying Microfluidics To RNA Manufacturing

How it works

Because of the small volume of RNA typically needed for a single therapeutic dose, a microfluidics approach creates a process that is better optimized for manufacturing RNA therapies. Utilizing the power of microfluidics, the operations of an entire manufacturing facility can be compressed into a much smaller package.

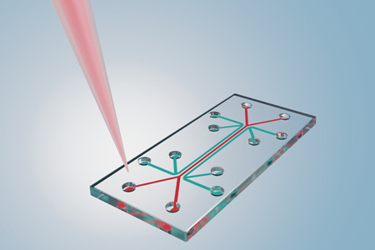

The extent to which microfluidics can be employed in RNA manufacturing varies. It is often used for RNA-loaded nanoparticle production, the simplest method being a Y- or T-shaped device that feeds the necessary solutions into the same channel to combine them.

However, microfluidics has shown utility in other parts of the manufacturing process as well, with some companies — such as Nutcracker Therapeutics and Kilobaser — conducting all reactions and purifications for each step of RNA manufacturing compressed on a microfluidic chip. In this scenario, reagents, fluids, air, and other raw materials are dynamically loaded onto the chips in an automated manner. The reagents can then move across minute channels into multiple chambers serving as the site of each reaction in a semi-continuous process.

Benefits of a microfluidics-based approach to RNA manufacturing

There are several distinct advantages that a microfluidic method of RNA manufacturing provides. These include:

Control

A microfluidic system facilitates precise control of reaction conditions, including the quantity of any given reagent used in the reaction, resulting in superior product quality and targeted particle morphology. Further, automated capabilities can be used to limit manual operations and reduce the opportunity for human error.

Analytics

On-chip measurement enables in situ process monitoring and, in turn, analytic capabilities that can lead to parametric releasability of RNA drug batches. This capability also leads to a radical reduction of the quality control burden.

Factory design

Because of its small physical scale, microfluidics often allows RNA manufacturing within a small footprint — meaning that a great deal can be accomplished in a small amount of GMP space, and that, in some cases, production units can be transported to areas where a therapeutic is needed most.

Speed of transition

The same platform can be utilized from early-stage research and development to investigational new drug-enabling studies and to manufacturing in commercialized settings — speeding transitions between these stages of drug development.

The Impact Of Flexibility

Utilizing the same chip-based microfluidic platform makes it possible to conduct a wide range of manufacturing, from very small to large scale, virtually eliminating the time- and resource-consuming “gap” of transitioning between different processes. This method ensures consistency in processes, which, in turn, ensures consistency in the quality of the end product.

Additionally, the flexibility of a microfluidics system means that it can be used for a variety of purposes. This versatility can be seen in the different companies that utilize it: While Kilobaser is focused on synthesizing RNA and DNA oligos for research, gene editing, and diagnostics, the Nutcracker Manufacturing Unit is designed and optimized for producing RNA therapeutics.

In practice, this means a microfluidic system can be used to make small amounts of each candidate for drug discovery and preclinical research, with the potential to scale up to full production for commercialized settings, when necessary. It also holds great potential for creating individualized therapies, or patient-specific drugs, which would require such a small amount of a drug product that traditional large-scale manufacturing would not be practical.

Tackling Challenges Of Scalability

While a microfluidics-based platform provides a great deal of flexibility in scale, one of the major challenges it faces is producing a commercial-scale supply for large patient populations. Due to the size of a single microfluidic manufacturing unit, and the volume of reagents that can be handled in a microfluidic system, a further specialized process will be required to produce greater quantities of an RNA product. To address this obstacle, researchers are currently developing next-generation processes that accommodate larger-scale production.

Reenvisioning RNA Manufacturing

As the medical field advances new, innovative RNA therapies, it is necessary to be open to rethinking our approach to traditional processes — including basic elements such as manufacturing. In addition to saving drug developers time and money, innovations in RNA manufacturing help to get new therapies to patients sooner. With the use of microfluidics creating scalability, speed, and other advantages, this approach to manufacturing RNA therapeutics is an important step in providing researchers and pharmaceutical companies more flexibility in creating their RNA products.

About the Authors:

About the Authors:

Sung-Hye Grieco is the former vice president of mRNA process development at Nutcracker Therapeutics. For more than 20 years, she has worked in process development for protein therapeutics, gene and cell therapy, and mRNA vaccines. During her career, she has had management and leadership roles at Genentech and Kite Pharma. Currently, she works at ReCode as vice president of CMC.

John Stubenrauch is chief operations officer at Nutcracker Therapeutics overseeing manufacturing, supply, quality, and product technical operations. Before Nutcracker, he was a vice president at Gilead Sciences following the acquisition of Immunomedics, where he was senior vice president of manufacturing. He has 25 years of experience in the biopharma industry supporting the manufacture of ADCs, biologics, vaccines, and synthetic peptides and molecules. Before Immunomedics, he worked at AstraZeneca and Merck. Stubenrauch earned a Ph.D. in chemical engineering from the University of Pennsylvania and an MBA from the Wharton School of Business.

John Stubenrauch is chief operations officer at Nutcracker Therapeutics overseeing manufacturing, supply, quality, and product technical operations. Before Nutcracker, he was a vice president at Gilead Sciences following the acquisition of Immunomedics, where he was senior vice president of manufacturing. He has 25 years of experience in the biopharma industry supporting the manufacture of ADCs, biologics, vaccines, and synthetic peptides and molecules. Before Immunomedics, he worked at AstraZeneca and Merck. Stubenrauch earned a Ph.D. in chemical engineering from the University of Pennsylvania and an MBA from the Wharton School of Business.