Accelerate LNP Manufacturing With Automated And Templated Process Development Services

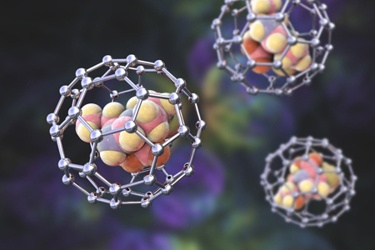

Manual, operator‑dependent steps have long defined lipid nanoparticle (LNP) formulation, but this approach brings a level of variability that is difficult to control. Real‑time adjustments to flow rates and other parameters introduce inconsistencies that can affect critical quality attributes, including particle size, distribution, and encapsulation efficiency. Even small fluctuations can lead to reduced yields and, for programs using costly nucleic acid payloads, substantial financial loss. As LNPs move from early development into clinical manufacturing, these challenges become even more pronounced—scaling up only increases the pressure to maintain tight control over CQAs.

Understanding the risks associated with manual processes is essential for teams aiming to confidently advance their programs to the clinic.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.