Improving Governance And Compliance With Knowledge Management

By Irwin Hirsh, Q-Specialists AB

Knowledge management and knowledge sharing provide powerful levers for removing obstacles to business success.

Here, in the final installment of our four-part series on knowledge management, I want to raise awareness of how knowledge management supports the demands of compliance and governance. As before, CMC process development and quality risk management (QRM) will be used for illustrative purposes, but I maintain knowledge management supports all aspects of the business.

Customer-Centric, Yes, But Who Is Your Customer?

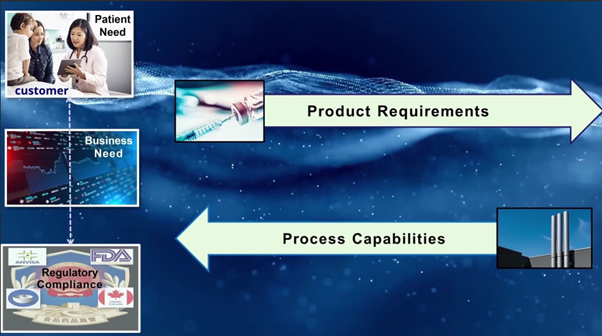

When working in a regulated industry, one would like to think that there is a direct connection between business excellence and compliance. This is not always the case. Too often, the lack of connection is due to an adversarial relationship between the business-minded and the quality-minded. To resolve this conflict, at least within my purview, I like to shift focus and priority to my customer. As discussed previously, I follow a three-customer model:

- the patient

- the business

- the regulatory authorities

Figure 1: Three-customer model

When there is a dilemma or a lack of clarity about justifications for actions or decisions, collecting the protagonists and performing suppliers, inputs, process, outputs, and customers (SIPOC) mapping will clarify which customer is the “first among equals” and help drive decision-making.

The routine and systematic application of quality risk management (QRM) during CMC development provides clarity about how to proceed in a practical manner without undue risk to the patient. Ambiguity is eliminated during the interplay of risk assessments and experiments (including the clinical trials) through which we continuously refine the connection between process parameters and product quality attributes.

Process Level And System Level Governance

Process level

When I audit any process, my questions follow this pattern:

- Please show me how this process is documented.

- Please show me evidence that the documented process is followed.

- What metrics on the performance of the process are collected?

- How are metrics used in the continuous improvement of the process?

Failure to answer any of these questions can usually be explained by one or a few of the “top 10 reasons your process is broken” discussed in the first article. When critical processes are assigned process owners dedicated to process maturation, all four questions above eventually can be answered and the focus of the business will shift from compliance to productivity, delighting customers and sparking innovation.

If you are part of a large organization and own high-level processes, you most likely delegate responsibilities to many people across the organization. However, delegation does not mean abandonment. Process owners must both empower and challenge their process delegates to mature the process. The process owner must ensure that processes bring direct, measurable, and positive results toward achieving the goals of the business.

This may require that you train your delegates in the fundamental tools of process mapping and process knowledge management. Will you do this yourself? What kind of signal does this send if you do not? Are you capable? If not, can you show humility and join them in the learning process? What kind of signal do you think that will send?

System level

For a business to run well, its processes must function together as a system to achieve common goals. It is simply not enough that processes are run well; they must be designed and implemented as part of a system that is used to achieve the stated business and quality objectives. In the language of Lean this is called Hoshin Kanri or, more commonly, strategy deployment.

A simple Google search will present dozens of books on Hoshin Kanri and strategy deployment.

When I asked ChatGPT for a simple outline, it provided a seemingly straightforward process:

- Top management crafts a strategic plan (like an annual road map) that focuses on a small number of critical issues.

- These goals express the company’s intent for growth and improvement.

- Middle management then translates these strategic goals into specific tactics and plans.

- Finally, frontline employees execute these plans in their day-to-day work.

However, in my experience the translation of strategic goals into actionable tasks both clearly understood and embraced by the frontline employees is a formidable challenge for middle managers. We have yet to conquer this challenge, as to this day there are still new books being published on Hoshin Kanri and strategy deployment.

Change Management

A considerable number of cultural and structural obstacles must be overcome for a successful strategy deployment, but a well-communicated X-matrix with easy-to-access digital bowling charts for progress updates will address exactly zero of them!

Figure 2: Hoshin Kanri X-Matrix

Obstacles To Implementation

Here are the top five obstacles I experienced as a middle manager:

- top-down decision-making,

- competing projects, both budgeted and pet projects,

- low levels of process maturity and constant firefighting,

- matrix reporting structures, and

- the disconnect felt by new or entry level workers between what they routinely do for work and strategic level goals.

From a knowledge management point of view, cultural resistance to change is due to a low level of process maturity that leads to a perceived lack of control over one’s work and in many cases a sense of futility or frustration. The shop floor where the work is done may have its own agenda for making changes or simply be running in firefighting mode. This is not the environment where any new strategic goals can be realized, unless the strategic goal begins with an investment in the time and effort to work on mapping and capturing process knowledge.

Process improvement initiatives started on poorly described or understood processes become random acts of Kaizen. In the best case, precious time and resources are wasted, and in the worst case the activity degrades the system and shortens the time to burnout.

Knowledge Sharing

Knowledge sharing, when missing or poorly done, seems to be the second greatest hindrance to strategy deployment.

Most leaders know that constant focus on goals is required to achieve success. However, in a business, the constant communication of goals by leadership becomes tiresome and meaningless if it is devoid of direct involvement by the leadership in the change process. Again, delegation does not mean abandonment.

Mutual Respect

Leaders must respect the people doing the actual work by understanding them. Communicating how the strategic goals are integral to everyone’s success is more meaningful when the pitch-back process of soliciting feedback is done long before the implementation phase has started.

Personnel whose operationally focused work is distinct from the work of big-picture strategic initiatives may feel even more disconnected when seemingly burdensome and suboptimal solutions become the global standard.

In such cases, knowledge management and knowledge sharing are critical to reversing this broken connection and ending its expansion.

Those responsible for the overall process that selected the global standard must inform those being impacted on a regular basis before implementation as well as capture their use case for the soon to be global standard.

The decision makers must also explain how the standard selected, while perhaps suboptimal in certain use cases, was the best overall choice due to the constraints of the business.

Enable Continuous Improvement

It’s important that operators and process users embrace changes because they will perform those processes routinely and thus become the process experts. These frontline workers become critical to continuous improvement and productivity gains. If they do not buy into the change, they will likely perform the process as before the change and/or be horribly inefficient and otherwise challenged with the new global standard. When this occurs, the site will never progress beyond the second audit question. Consequently, the new process will likely flounder and then wither, thus killing productivity and reinforcing disconnects and discontent.

Cross Business Lines

The most important processes in a company run across many different business areas. If any one area tries to own a process without buy-in and close cooperation from the other areas, the process will suffer and thus the business.

Risk management is of great concern for every business. However, you must ask: Who is your customer? Who is it that suffers the hazard should it manifest? The patient, compliance (the regulatory authority), or the business? Maybe even all three, but with different levels of severity?

Take, for example, an accident wherein a worker becomes injured on the production line at a manufacturing site. Because of this accident production is stopped and the batch must be assessed for impacts on quality. In this scenario, at least three different departments must report this into their systems:

- health and safety,

- quality, and

- supply chain.

However, the level of risk acceptance for the same event will be different for each corresponding business unit based upon the focus area(s) of the reporting department. Each group is likely to report the incident to the corporate office (for me, it was always to finance) but with their own point of view. Depending on how clearly the incident was reported, it may not be understood by the corporate function as one incident but rather as three.

A common risk reporting tool with a common language and understanding of risk classifications is required to resolve this challenge. Although this is a corporate-level item that runs across almost all lines of business, the advice given on the tactical level for process

development QRM as explained in the video below is very relevant in that it provides the insights needed to create a common language and understanding of risk.

About the Author:

Irwin Hirsh has nearly 30 years of pharma experience with a background in CMC encompassing discovery, development, manufacturing, quality systems, QRM, and process validation. In 2008, Irwin joined Novo Nordisk, focusing on quality roles and spearheading initiatives related to QRM and life cycle approaches to validation. Subsequently, he transitioned to the Merck (DE) Healthcare division, where he held director roles within the biosimilars and biopharma business units. In 2018, he became a consultant concentrating on enhancing business efficiency and effectiveness. His primary focus involves building process-oriented systems within CMC and quality departments along with implementing digital tools for knowledge management and sharing.

Irwin Hirsh has nearly 30 years of pharma experience with a background in CMC encompassing discovery, development, manufacturing, quality systems, QRM, and process validation. In 2008, Irwin joined Novo Nordisk, focusing on quality roles and spearheading initiatives related to QRM and life cycle approaches to validation. Subsequently, he transitioned to the Merck (DE) Healthcare division, where he held director roles within the biosimilars and biopharma business units. In 2018, he became a consultant concentrating on enhancing business efficiency and effectiveness. His primary focus involves building process-oriented systems within CMC and quality departments along with implementing digital tools for knowledge management and sharing.