Optimizing Filling Technology To Minimize API Loss

By Samuel Chia, Director of Aseptic Manufacturing, Pharmaceutics International, Inc.

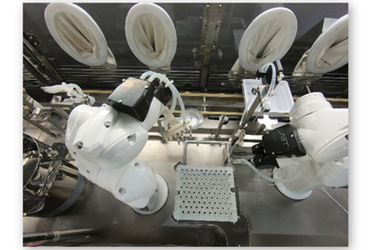

The paradigm shift in today’s manufacturing landscape toward smaller batches for more targeted patient populations is dramatically impacting how drugs are developed and manufactured. With active pharmaceutical ingredient (API) values continuing to climb as batch sizes go down, upstream production costs are increasing significantly. This means even the smallest loss of API at the fill/finish stage can waste thousands of dollars and potentially result in a lower-yielding manufacturing lot. It can also lead to under-dosed finished product and annul the beneficiary therapeutic effects for the patient. Fortunately, new advances in filling technology offer solutions that can minimize lost API and eliminate sources of risk while still meeting the regulatory requirements for testing and quality assurance.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Bioprocess Online? Subscribe today.