Automating Time-Consuming Water Quality Tests

By Jason Dickens and Mike Ponstingl

Custom Sensors & Technology (CST) was established in 1980 and has provided process monitoring products and solutions across various industrial sectors such as petroleum, chemical, food processing, pharmaceutical, and biotherapeutics. CST is uniquely positioned to service the water quality industry with its portfolio of products and technologies. Several of its current and emerging technologies have been applied to water quality and similar applications. CST leverages its 42 years of across industry experiences to tailor its technologies for rapid, robust, and fit for purpose real-time monitoring and control.

In recent years, CST has embodied its rich background and established technology leverage to continue to innovate and develop an autonomous monitoring solution of trace metal cations and anion applications for the water quality industry. This innovative product, NARWHAL, utilizes established and regulated methods to individually determine copper, iron, silica, manganese, aluminum, calcium, and other analytes of interest thereby affording a mitigation approach to costly and time-consuming laboratory methods such as titration, atomic absorption (AA) to inductive coupled plasma mass spectroscopy (ICP-MS).

Continuous innovation, product adaptation and a consistent portfolio of establish product offerings is Custom Sensors’ future vision for the industries it serves to ensure rapid, robust, and fit for purpose analyzers or sensors for real-time monitoring and control.

CST technologies are underpinned by photometric detection along with either automated sampling or in situ (in-line) analysis. CST photometric products enable UV-vis absorption, fluorescence, and near infrared detection for reliable real-time analysis of various constituents or analytes of interest. CST products are developed, manufactured, and evaluated under the intended process and environmental conditions to ensure reliable real-time operations. For example, certain products have been vetted under harsh processes and environmental conditions such as high pressure, temperature, or flow. This rich experiential background positions CST to provide product solutions that are fit for purpose from the initial costumer inquiry to final product delivery.

Introducing NARWHAL

NARWHAL automates time-consuming lab-based tests for an array of water quality applications. Setting up is simple, and the 7” intuitive touch screen allows for easy customization and data monitoring – including real-time indication of process conditions. With faster turnaround, higher testing volume, and increased precision and reproducibility, NARWHAL makes a splash both in reducing human error and increasing productivity in the lab.

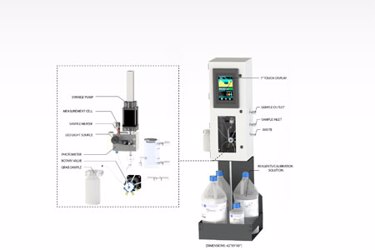

NARWHAL is designed to perform fully automated colorimetric measurements and deliver the product of the chemical reaction to an analysis cell in a process setting. The system first retrieves a known volume of sample from a stream and mixes it with up to three reagents in succession. After each reagent addition, a mixing cycle is performed followed by a variable reaction delay.

Once the reagent addition process is complete, the final solution is transported to measurement cell where the compound of interest can be determined via an absorbance measurement. NARWHAL is designed to be mounted near the pipeline containing the sample of interest which is retrieved from the pipeline via a fast loop. NARWHAL also utilizes a grab sample chamber to make analyzing small sample volumes quick and easy.

About Custom Sensors

Since our establishment in 1980, Custom Sensors & Technology (CST) has provided customers with robust integrated process monitoring equipment and accessories. Our years of experience designing sample handling systems and photometric instruments for industries such as food/beverage, pulp/paper, pharmaceutical/bio-processing, and chemical/petrochemical allow us to tackle the next set of process analytical challenges. CST is a full-service provider offering application engineering and development, opto-mechanical-chemistry integration design/fabrication, factory acceptance testing, custom installations, customer support, and in-house repair and calibration. We have a strong commitment to continued development of new products as evidenced by our patent portfolio and long-term historical sustainability.

Custom Sensors & Technology commits itself to providing our customers with products that ensure profitability, respect for our planet and the safety of staff and community. We pride ourselves on our ability to devise innovative process monitoring solutions for difficult applications that are simple and safe to use and implement. Our goal is to create products that add value to your process, and we stand behind our workmanship.

About the Authors

Mike Ponstingl, president and founder, Custom Sensors and Technology

Mike Ponstingl founded Custom Sensors and Technology in 1980 along with a group of scientists and engineers from Monsanto and has built the company up into a world-class engineering and process instrumentation company serving global customers. With 41 years of industry experience behind him, Mike has led the company on a journey of strategic growth through his impressive entrepreneurial vision and determination. Mike spent his first 10 year working for Rockwell International, Radian Corporation, and Beckman Instruments before founding Custom Sensors and Technology.

Jason Dickens, PhD, Technical Consultant

Jason Dickens provides technical consultation to Custom Sensors and Technology based upon 20 years of biopharmaceutical process development experience across disparate biotherapeutic modalities and associated biomanufacturing processes. He has also successfully led various advanced process control initiatives within the sector that have enabled innovative GMP process control and real-time release capabilities, as well as enhanced process understanding. His industrial experience includes technical leadership roles at Eastman Chemical Co., GlaxoSmithKline, Biogen, Metabolon, and the Duke Human Vaccine Institute.