SINGLE-USE TECHNOLOGY FEATURED ARTICLES

How Can You Mitigate The Risks Of Single-Use Bags?

How Can You Mitigate The Risks Of Single-Use Bags?

The loss of product as a result of bag failure isn’t just an annoyance; it’s an expense, and a costly one at that. However, Chuck Hart, director of manufacturing at Prolong Pharmaceuticals, says with proper fitting and handling, these concerns can be mitigated.

-

Standardized Extractables Testing Advances Single Use Adoption

The Standardized Extractables Testing Protocol For Single-Use Systems In Biomanufacturing written by BPOG members last year establishes a foundation from which to create a standardized approach to extractables testing. However, since its release, there have been some questions and discussions about how to effectively implement the protocol.

-

Single-Use Standardization: Is It Holding Back The Biopharma Industry?

The data from BioPlan Associates’ 12th Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production speaks to the industry’s ongoing desires for standardization in single-use devices. As usage of these disposable devices increases, the gap between the importance of standardization and end-users’ satisfaction with their supplier’s standardization efforts has steadily been worsening.

-

Top Single-Use Suppliers Make Standardized Equipment A Reality – Part 2

Industry experts offer the benefits of standardized single-use equipment to both suppliers and users, as well as how it addresses some of the biggest objections to equipment standardization, as well as offer insight from the eyes of a user.

SINGLE-USE TECHNOLOGY WHITE PAPERS & CASE STUDIES

-

Determination Of kLa Values Of Single-Use Bioreactors

Because single use bioreactors offered by manufacturers vary in parameters critical for oxygen transfer, they are often not comparable to each other and to conventional glass and stainless steel vessels.

-

Effect Of Sterilization On Mechanical Properties Of Silicone Rubbers

Silicone rubber is widely used in the pharmaceutical industry where sterilizability is an essential requirement for all fluid transfer equipment. Pharmaceutical products must be sterilized frequently and repeatedly by high level energy and/or chemical vapor in order to eliminate bacterial surface contamination.

-

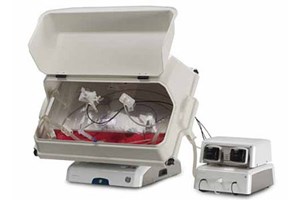

Biological Contamination Events In Isolators: What Lessons Can Be Learned?

Microbiological deviation and biological contamination events have been observed in pharmaceutical isolators including those used in production, sterility test and pharmacy aseptic services. By James Drinkwater, Bioquell UK Process & Compliance Director

-

Protein A Alternatives: Mixed Mode Resins For High Throughput mAb Feedstocks

Mixed mode resins can serve as an alternative to protein A in intermediate processing. Implementation of mixed mode resins can reduce water required for filtration and time for column loading.

-

Sani-Tech® Ultra White Paper

For several years, pharmaceutical manufacturing professionals have increasingly stated concerns about material leachables and extractables and their impact on the products they produce. Fluid transfer systems that include flexible tubing have been at the forefront of this discussion.

-

Guidelines For Proper Filtration And Delivery Of Samples To On-Line Process Analyzers

Increasingly precise process control strategies, often linked to computer control, have accelerated the use of sophisticated on-line chemical composition analyzers in plant applications. Instruments such as gas and liquid chromatographs, ion chromatographs, laser optic instruments, atomic absorption instruments and specific ion analyzers, which were rarities in laboratories ten years ago, are now found routinely in plant settings. By Ken Perrotta, Division Engineering Manager