ABOUT MILLIPORESIGMA

The growing demand for new therapies, persistent pressure to reduce costs, and the clinical success of novel modalities are driving the biopharmaceutical industry to adopt new strategies to increase the speed, efficiency, and agility of manufacturing. A variety of approaches are available to address these imperatives.

Monoclonal antibodies (mAbs) and recombinant proteins have templated production workflows. Here, the focus is on exploring and integrating strategies defined by Biopharma 4.0 – the digital transformation to intensified, closed, connected, or continuous processing. For these companies, the key question is: “Where do I begin?”

In contrast, relatively new modalities such as mRNA and cell and gene therapy present different challenges. Cell and gene therapies are highly complex, lack a manufacturing template, and innovators must operate in a regulatory environment that continues to evolve. When developing and manufacturing mRNA-based therapeutics, among the most pressing objectives are to improve process efficiency and mRNA product stability.

For innovators of these novel modalities, access to new technologies and a breadth of expert services are critical success factors as they ask: “How can I improve my process?”

MilliporeSigma, the life science business of Merck KGaA, Darmstadt, Germany, empowers you to optimize and streamline your development and manufacturing processes. Whether you are producing mAbs and recombinant proteins, or highly complex, novel modalities, we will help you meet your goals for speed, efficiency, and agility.

We offer a convergent end-to-end portfolio of advanced, closed processing-ready technologies with extensive documentation for upstream and downstream operations, process analytical technologies (PAT), data analytics, automation and control software, contract testing and analytical development services, non-GMP environment labs, and CTDMO services for mAbs, high potency active pharmaceutical ingredients (HPAPIs), antibody drug conjugates (ADCs), mRNA, and lipid nanoparticle (LNP) formulation.

VIDEOS

HOT PRODUCTS

-

Perfusion at process development scale

The Mobius® Breez Microbioreactor is a 2 mL automated single-use perfusion cell culture platform designed to support gentle, adaptable, and reproducible cell processes.

-

Designed to purify biologics at clinical and process scale, the Mobius® FlexReady Solution with Smart Flexware® Assemblies is flexible, allowing you to have a single system for tangential flow filtration (TFF) at various scales.

-

Bio4C Orchestrator™ connects to individual unit operations from a centralized “orchestration layer” for complete visibility, monitoring, and management of regulatory-compliant biomanufacturing systems and processes. The software's consolidated control optimizes processes improving quality and compliance while reducing human errors and operating costs.

-

To ensure optimum equipment uptime and regulatory compliance while mitigating risks, MilliporeSigma has developed System Service Reliance Plans; a complete range of services for your systems and equipment. These comprehensive service and support packages allow you to select a coverage level that best fit your needs

-

MilliporeSigma’s Mobius® single-use mixing solutions deliver advanced technology for mixing pharmaceutical ingredients from intermediate to final drug products and for the preparation of process solutions, such as buffers and media. Unlike traditional stainless-steel mixers, single-use mixers reduce downtime due to CIP, SIP, cleaning validation, and process engineering. Mobius® single-use mixing solutions also offer operational flexibility as they can be up and running in less than five minutes. They are capable of mixing speeds up to 1000 RPMs meeting the broadest range of mixing production requirements. Mobius® flexibility offers you a choice of just the right filter, connector, tubing options for your specific application and environment, including sterile interfaces, from fermentation to final fill. Sizes range from 10 L to 3000 L.

-

You’re developing lifesaving gene-modified cell therapies and need to manufacture lentiviral vector as quickly as possible. But scale-up and regulatory hurdles make the path to the clinic slow and labor intensive.

We're here to help.

-

From your bioreactor to final sterile filtration, the new NovaSeptum® GO sampling system lets you sample processes the way you want. Flexible formats and volumes adapt to your process for robust, reliable monitoring and quality assurance.

-

Cell culture media are important for process efficiency and mAb quality. Production media support initial cell growth and production, while the feeds replenish depleted nutrients required for cellular function and maintain and extend the production phase in fed-batch mode.

-

Cellvento® CHO media are designed to support growth and maintenance of specific CHO cell lines in suspension cell culture for expression of monoclonal antibodies and recombinant proteins. The new Cellvento® 4CHO-X Expansion Medium supports cell expansion including N-1 perfusion for Chinese Hamster Ovary (CHO) cell lines.

-

In recent years, the development of media used to expand and mature adult stem cells has greatly increased the success rate of adult stem cell therapy and the breadth of potential stem cell-based therapies. To obtain enough cells, ex vivo expansion has been utilized to ensure successful engraftment and economize the manufacture of both allogeneic and autologous therapies.

BROCHURES

- An NGS-Based Platform To Streamline Your Genetic Stability Testing

- ADC And Bioconjugation Center Of Excellence

- Comprehensive ADC And Bioconjugation Services For Targeted Therapies

- Novel Enzyme For Nucleic Acid Removal At High Salt Concentrations

- Endonucleases With High Purity And Activity For Any Application

- CTDMO Services To Fast-Track The Advancement Of mRNA-Based Drugs

- Granulated Materials

- A Versatile And Modality-Agnostic Aseptic Autosampling Solution

- Expert Partnership Contract Testing Services

- A 2 mL Automated Perfusion Cell Culture Platform

WEBINARS AND PODCASTS

PRODUCT GUIDES, DATA SHEETS & APPLICATION NOTES

- Simplifying CHO Cell Line Genetic Stability Testing

- AAV Process Intensification Using High Salt Lysis And Salt Tolerant Endonuclease

- Novel Enzyme For Nucleic Acid Removal At High Salt Concentrations

- Characterization Of Host Cell Proteins By Liquid Chromatography - Mass Spectrometry

- A Versatile And Modality-Agnostic Aseptic Autosampling Solution

- Scalability And Performance Of Mobius® iFlex Bioreactors

- Viscosity-Reducing Excipients For Protein Formulation

- Viscosity Reducing Excipients For Filtration Process Improvement

- Automated Aseptic Sampling For Upstream Bioprocessing

- A 2 mL Automated Perfusion Cell Culture Platform

NEWS

- MilliporeSigma Announces Support Of SaudiVax In Becoming First Developer And Manufacturer Of Halal Vaccines And Biotherapeutics In Saudi Arabia

- MilliporeSigma To Manufacture Next-Generation Biotherapeutics For Alteogen

- MilliporeSigma Announces Organizational Transformation To Strengthen CDMO Offering And Accelerate Future Growth

- MilliporeSigma’s Bio4C Orchestrator™ Software Optimizes Processes, Improves Compliance And Time To Market

- MilliporeSigma Advances Bioprocessing Capabilities With Raman Technology Sensor Acquisition

- MilliporeSigma Accelerates Readiness Of Bioprocessing Facility Of The Future

CONTACT INFORMATION

MilliporeSigma

400 Summit Drive

Burlington, MA 01803

UNITED STATES

Phone: 978-762-5100

NAVIGATING THE EMERGING BIOTECH ECOSYSTEM

FEATURED ARTICLES

-

Here, we describe the use of whole genome sequencing to perform a comprehensive assessment of genetic stability in clonally derived CHO cell banks using the Aptegra™ CHO genetic stability assay.

-

Discover a genetic stability assay that is fully validated to GMP quality standards and outperforms traditional testing methods with its enhanced speed and accuracy.

-

By addressing the complex needs of cell culture from the start, organizations can take steps to optimize their process, ensuring they are maximizing productivity and product quality.

-

Explore specific examples of challenges commonly encountered in the process and analytical development of next-generation conjugates as well as corresponding solutions for each.

-

In the production of adeno-associated virus (AAV) vectors, cell lysis involves challenges addressed through high salt concentrations and a salt-tolerant endonuclease, enhancing titer and infectivity.

-

Examine how intensifying AAV production with high salt lysis and Benzonase® Salt Tolerant endonuclease enhances viral yield and infectivity while ensuring DNA removal for patient safety.

-

Explore process and analytical development capabilities that can help you advance your formulation to GMP Manufacturing.

-

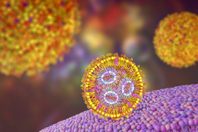

Lipid selection impacts the final LNP drug product and the LNP process. Review critical quality considerations for lipids and the process requirements for successful commercial-scale manufacturing.

-

Explore the differences between research-use-only oligonucleotides and those manufactured in compliance with GMP 21 CFR 820.

-

Explore an established liquid chromatography – tandem mass spectrometry (LC-MS/MS) method for characterization of residual HCPs in monoclonal antibody (mAb) products.

-

Explore approaches for the capture and separation of capsids, upstream strategies for reducing the level of empty and partially filled capsids, trends in AAV capsid design impacting purification, and more.

-

Utilizing single-use bioreactors in intensified fed-batch and perfusion processes can help manufacturers produce a high-quality drug supply while reducing facility footprint and production costs.

-

In this study, industry experts share their perspectives and plans related to the implementation of fully closed processing. Explore the drivers and challenges of fully closed processing and more.

-

When it comes to determining the appropriate analytics to inform early development, there are a number of variables to consider surrounding cost, operator expertise, and throughput.

-

Explore the viscosity-reducing abilities of excipients and excipient combinations, the impact of protein viscosity on injection force, and much more.

-

We demonstrate two filtration methods evaluating the effect of the excipients in the Viscosity Reduction Platform on ultrafiltration processes used to produce a highly concentrated mAb formulation.

-

Explore PAT, the use of automated sampling technology to accelerate analytical and quality control methods, the benefits of automated sampling in upstream process development, and more.

-

The emerging trends in the biopharmaceutical industry are driving an even greater need for modular facilities and closed processing. Learn about the progression toward closed processing and more.

-

With continuously evolving gene therapy regulations and guidance and limited time during development for testing, here are four points to consider when planning product-release testing of your gene therapy product.

-

The COVID-19 pandemic underscored the vulnerability of global supply chains. Explore lessons learned from the pandemic, the concept of supply chain resilience, what to look for in a supplier, and more.