Untapped Potential Of Protein A To Be Highlighted At BPI Conference

By Trisha Gladd, Editor, Life Science Connect

According to a recent McKinsey report, biopharmaceuticals are the fastest-growing part of the pharmaceutical industry. They currently have an annual growth rate of eight percent, which is double that of traditional pharma. As companies find more success in new areas of opportunity, such as biosimilars and cell therapy, that growth will undoubtedly continue. However, as science and technology advance, the need to do things better, faster, and cheaper remains, which is what some of the industry’s top experts will discuss when they meet in Boston this October for the 2015 BioProcess International (BPI) Conference.

Pete Gagnon, group manager for downstream processing at the Bioprocessing Technology Institute in Singapore, is one of these experts. His presentation, Protein A: the Fine Print, is one of several scheduled during the pre-conference symposia track, Innovation in Process and Product Development Technologies for Biopharmaceutical Development. He recently sat down with me to talk about what his presentation will cover as well as where he and his team find inspiration for new ideas.

Trisha Gladd: What is the Bioprocessing Technology Institute?

Pete Gagnon: BTI is one of 21 research institutes administered by the Singaporean Agency for Technology and Research (A*STAR). It is a non-commercial entity that is about 50 percent publicly funded, with the remainder coming from industrial collaborations. BTI, with a staff of about 120, is configured like a small biopharma company to facilitate interactions with industrial biopharma and solution providers. The Downstream Processing Group includes 20 team members dedicated to developing profound improvements in downstream.

Gladd: What can the audience expect you to cover in your presentation, New Technologies in Bioprocess Development?

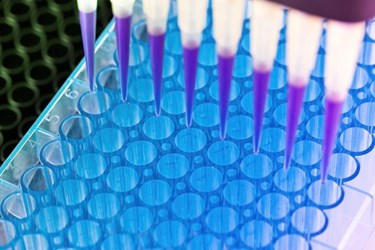

Gagnon: One of our major contributions to date has been the discovery that dead cell contents do not break down fully during cell culture, and a composite class of partially degraded contaminants imposes major performance deficiencies on all purification methods. That contaminant class is chromatin heteroaggregates. With protein A, they depress capture capacity, inflate contamination, promote aggregate formation, and reduce IgG recovery. If you remove them in advance, it provides you with the experimental controls to look at protein A and other fractionation methods at a level of detail that has never been possible before – because those details were previously masked by chromatin heteroaggregates. This presentation will summarize major new findings about the way protein A really works and show people how to use it much more effectively.

Gladd: What trends are going on in the industry that inspired new technologies?

Gagnon: We were actually more inspired by areas lacking trends. For example, the performance of protein A affinity chromatography has been far below what it should be capable of for decades, but it has worked well enough to get products to market so there has been little motivation to address the limitations. We concluded that if protein A performance could be dramatically improved, it might be possible to eliminate polishing steps and go the further step of also improving product quality.

Gladd: What do you think the biggest challenges are in today’s development processes and what does the industry need to do to overcome them?

Gagnon: The biggest challenge is inertia. Increasing pressure to reduce costs unfortunately tends to lock obsolete technology in place. That in turn discourages solution providers from developing more effective alternatives. Regulators try to promote innovation through process analytical technology (PAT) and quality by design (QbD), but it is up to the industry to take a stand and ask the question: What is really possible? The potential is there. The industry just needs to make it happen.

Gladd: Where do you see the most growth of innovation in biopharma? Where do we need to see it but don’t?

Gagnon: It depends on how you define innovation. If you include packaging (disposables) and automation (simulated moving bed chromatography), there is plenty going on in downstream, but really, those advances are more in the nature of engineering and optimization than basic innovation. Improvements like this are necessary, welcome, and very valuable, but we are overdue for advances that fundamentally change the way people think about how to get the job done.

Gagnon’s presentation is scheduled for Monday, October 26th, at 3:30 PM. For more on the other presentations scheduled for this track, download the entire agenda here.