Jet Feed Injector (Powder to Liquid) System

The PST system can be operated in batch or continuous way. A set of valves allows the discharge or the re-circulation of the mixture. The powder characteristics and the flow capability will define whether a longer sucking time is required.

- Allow to mix powders into liquids using the Ventiry principle

- Homogeneous mixing without lumps or agglomerates

- Dust free operation

- Mobile or fix units

- Easy to use

- High flexibility

- Quick dissolving & mixing

- No parts in movement

- Sterile execution

- Easy to clean

- Small residual quantities in case of recipe change

- Low energy consumption

- Explosion proof execution

- Jacketed (coolable or heatable) execution depending on product requirement

- Large capacity range

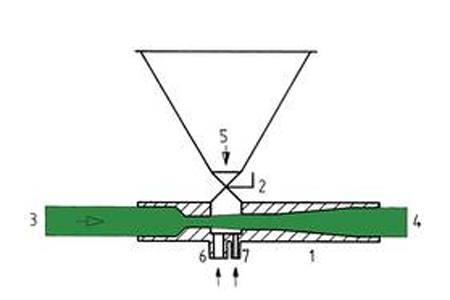

The pump transfers the liquid (3) to the inlet of the Large jet feed injector. 2,5 bars are sufficient to create the vacuum effect in the injector. When the valve for powder infeed is open, the powder is immediately dissolved (particles by particles) into the liquid. The valves (6) and (7) allows the addition of small quantities of powders or liquids.

1 Large jet feed injector

2 Valve for solids

3 Flow direction

4 Output of mixture

5 Input of solids

6 Input of liquid

7 Input of small quantities