Antibody-Drug Conjugate

EirGenix provides client-oriented contract development and manufacturing services for biologics, especially monoclonal antibodies and biosimilars. Combining the capabilities of EirGenix’s strategic partner, Formosa Laboratories, Inc, a high potency API manufacturer, we offer integrated services for Antibody Drug Conjugate (ADC) development and manufacturing.

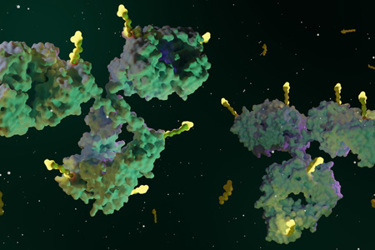

ADC Introduction

Antibody drug conjugates are now a viable and effective therapy for some diseases including cancer and hematological diseases. Four drugs have already been approved and there are more than 60 others in the clinical trial pipeline. The major approach is to target cancer cells directly by linking high potency chemicals (eg. derivatives of toxins) onto monoclonal antibodies. This approach enhances potency and reduces toxic side effects by targeting the monoclonal antibody to specific cells. There are three key components in developing ADC: a specific monoclonal antibody, a high potency chemical, and an effective linker. EirGenix's major business is to support our clients’ biologics development by providing the best monoclonal antibodies, high potency chemicals, and effective linkers in an integrated service platform.

Monoclonal Antibody Development and Production

The monoclonal antibody plays the carrier role in ADC development with its specific targeting mechanism. Production of monoclonal antibodies is EirGenix's expertise. EirGenix is capable of supporting our clients from cloning a specific DNA to creating stable cell lines for antibody development. We can follow either non-GMP or GMP level production. EirGenix's mammalian cell facility includes a 100-500L stainless steel bioreactor train, and a 50-200-1000L single use bioreactor train. EirGenix's Zhubei facility will have multiple 2000L trains for commercial manufacturing. EirGenix is offering our in-house developed biosimilars for licensing, to shorten client's ADC development time and related resources.

Key equipment includes, but not limited to:

- 100-500L Stainless Steel and 50-200-1000L Single Use Bioreactor trains

- Millipore POD and 3M CUNO filtration system

- 0.5~ 7 m2 MF/UF and 0.1~14 m2 UF/DF Filtration concentration units

- central control system biopharmaceutical manufacturing facility

High Potency Chemicals

Formosa Laboratories is EirGenix's strategic partner, and provides expertise in high potency drug manufacturing. Formosa Laboratories supplies high quality API to the US, EU and significant global markets. With outstanding innovation capability (58 chemists, 9 granted process patents, and 22 patents under review) and 2000L scale of high potency APIs manufacturing capacity, Formosa Laboratories provides our clients with integrated services for research and manufacturing of high potency chemicals used in ADC.

Key equipment includes, but not limited to:

- 50-1000L SS Reactor

- 50-1000L Chromatography Column

- Isolator (glove box)

- 280L Falling Film Evaporator

Linkers

Linkers are a key component in ADC. An effective linker needs to be stable in the circulatory system, but easily broken down in the target cells. EirGenix has partnered with the leading linker development companies. Combined with the capability of EirGenix and Formosa Laboratories, we are the best partner for client's ADC development and manufacturing project.

Small scale facility

- Reactors: 10-60L

- Typical batch size: 50-250g

- Tangential flow filtration

- WFI

- Laminar flow hood

- Isolator for toxin handling

Large scale facility

- Reactors: 100- 600 L

- Typical batch size: 1.5- 3.0 Kg

- Tangential flow filtration units

- WFI, clean steam, CIP

- Aseptic filling (cryovessel or RABS)

- Isolator for toxin handling